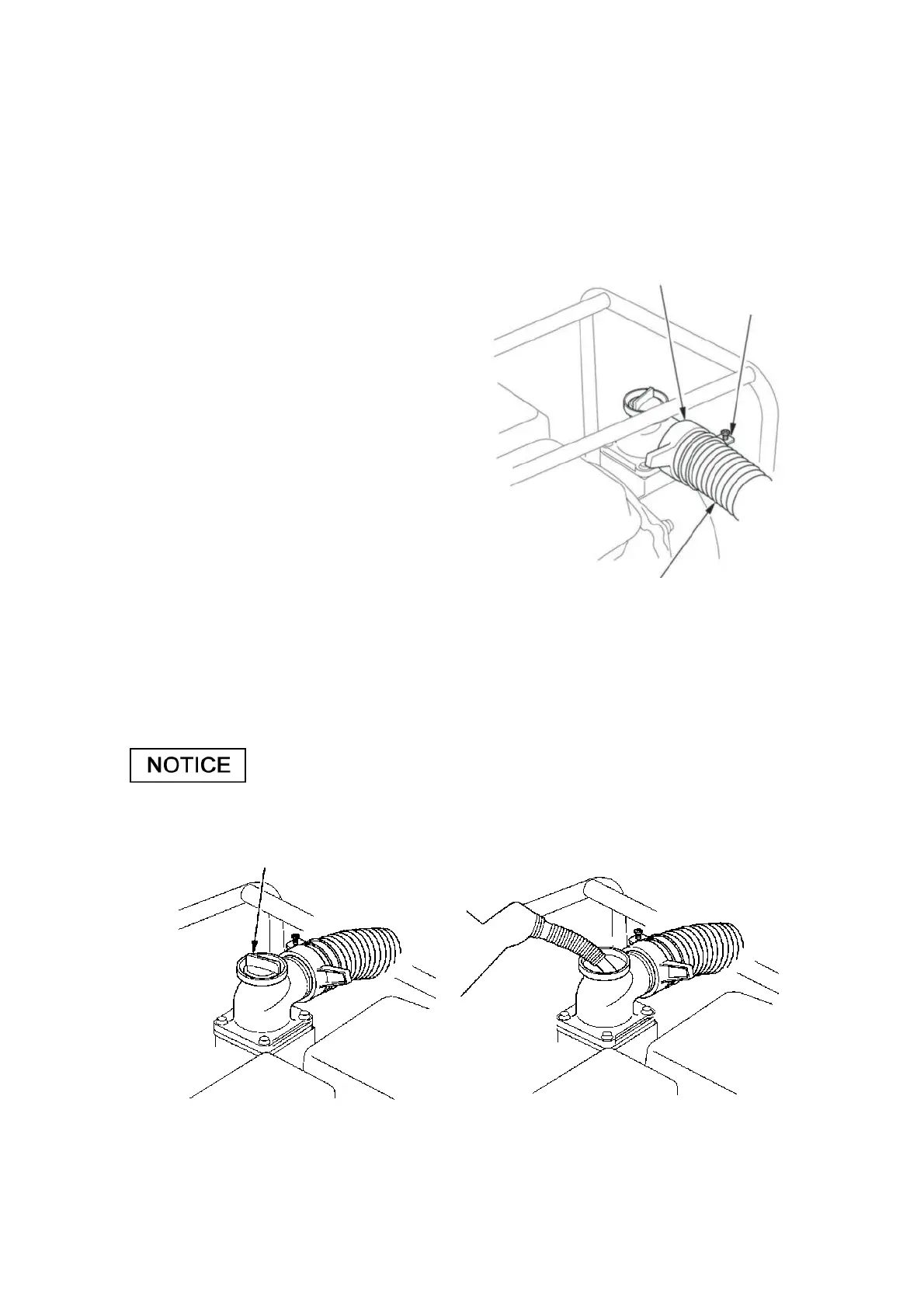

DISCHARGE HOSE INSTALLATION

Use a commercially available hose and hose connector, and clamp provided with

the pump.

It is best to use a short, large-diameter

hose, because that will reduce fluid

friction and improve pump output. A long

or small-diameter hose will increase fluid

friction and reduce pump output.

Tighten the hose clamp securely to

prevent the discharge hose from

disconnecting under pressure.

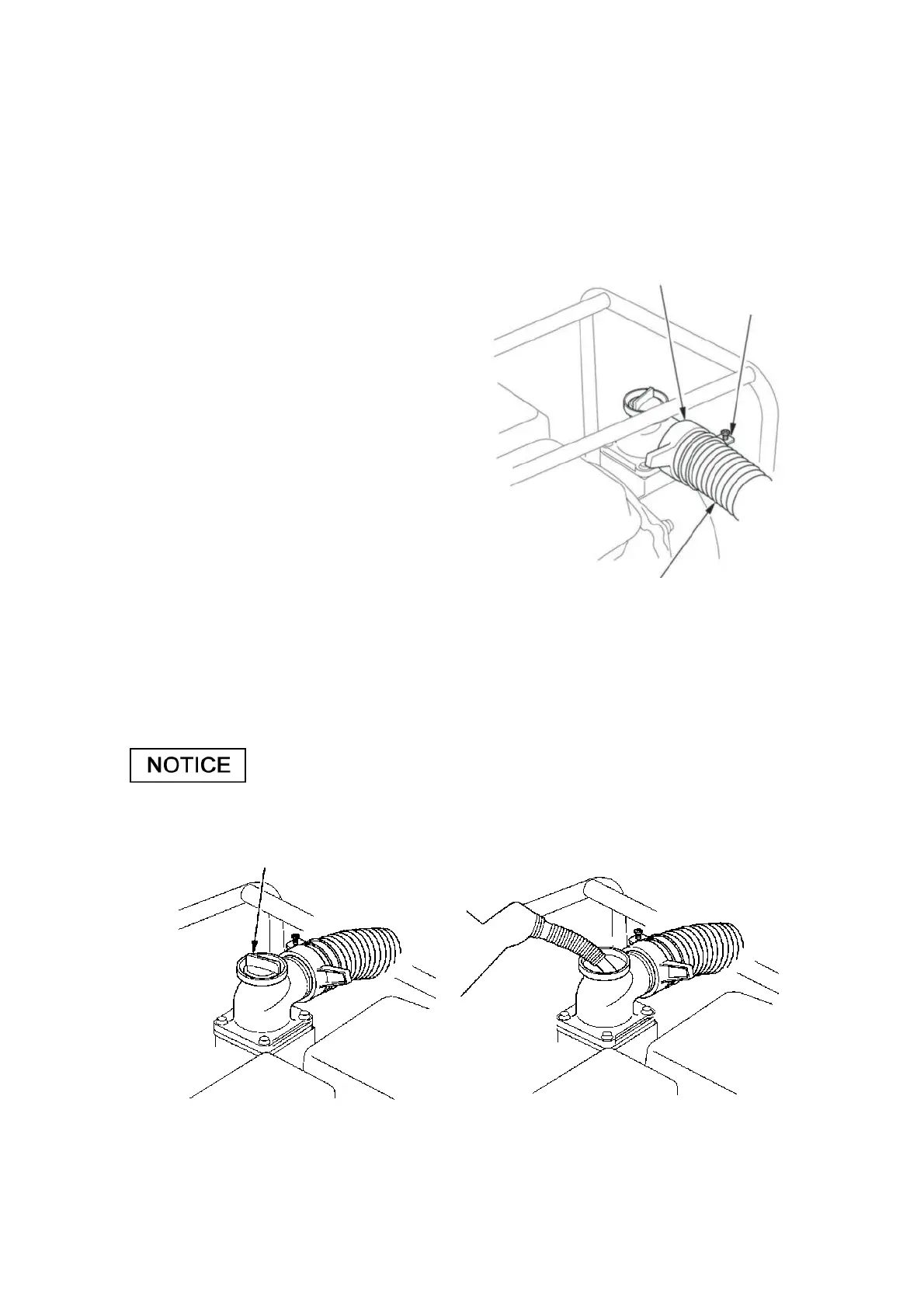

PRIMING THE PUMP

Before starting the engine, remove the filler cap from the pump chamber, and

completely fill the pump chamber with water. Reinstall the filler cap, and tighten it

securely.

Operating the pump dry will destroy the pump seal. If the

pump has been operated dry, stop the engine immediately,

and allow the pump to cool before priming.

DISCHARGE HOSE

PRIMING WATER FILLER CAP

Loading...

Loading...