22

FIGURE 28

Assembly Instructions - 60” (cont.)

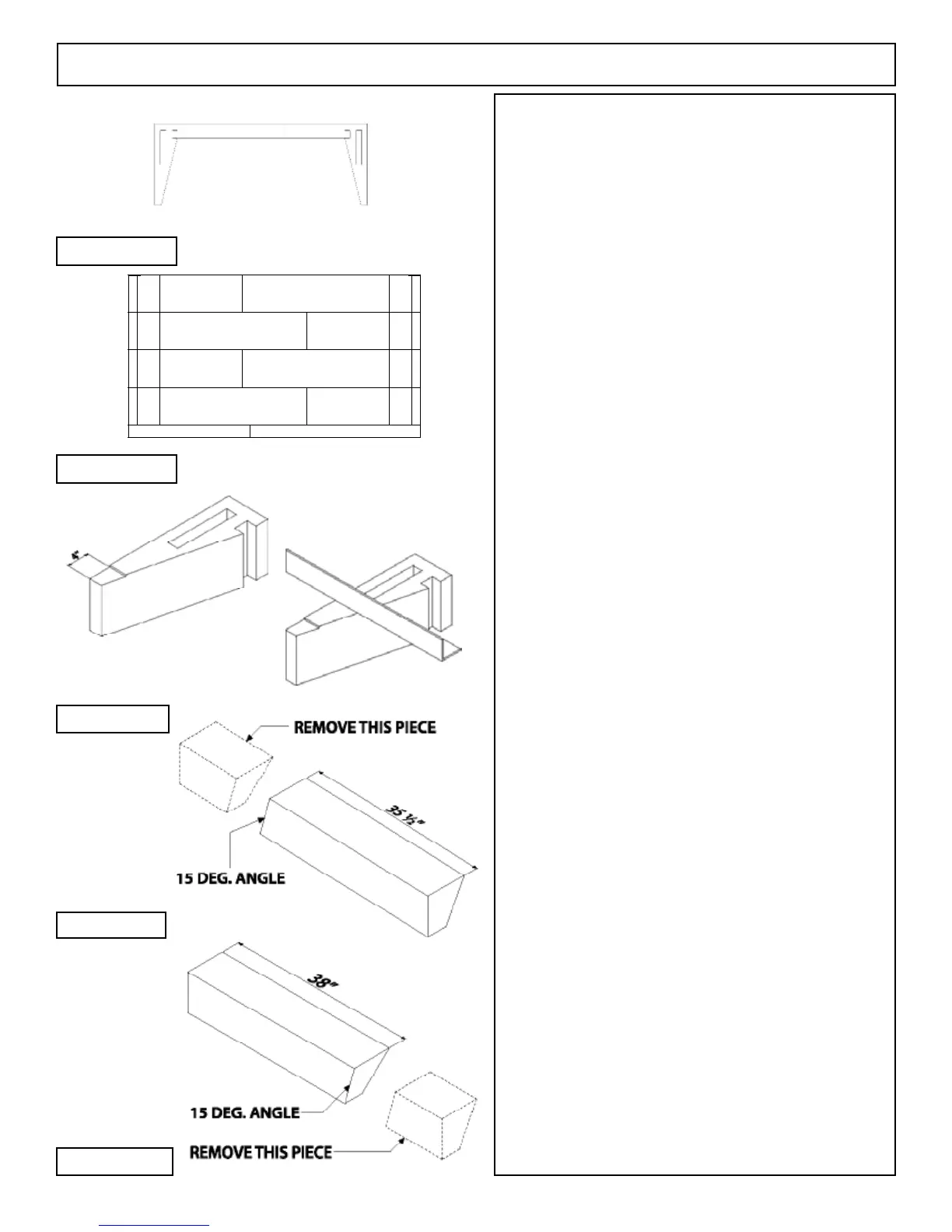

FIGURE 29

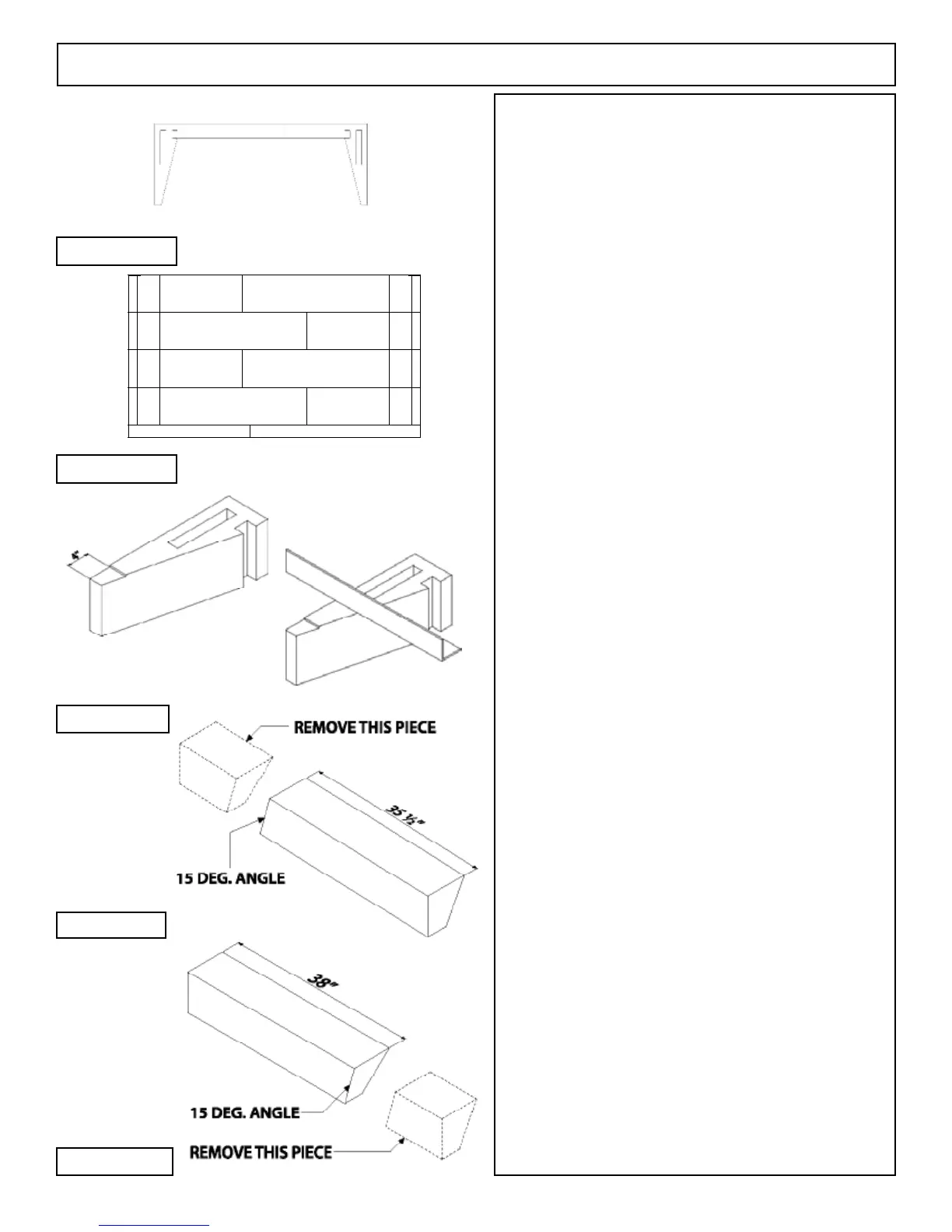

FIGURE 30

FIGURE 31

FIGURE 32

Step 5: Continue stacking the remaining three courses of

back wall. Be sure to reverse the positions of the 38-1/2”

M67 and the 22-1/4” M67 in each successive course.In this

way, the butt joint where the two M67 components meet are

staggered from course to course.

The overall width dimension at the back of the

rebox should be 73-1/2” including the sidewalls.

(Figure 29).

Step 6: Steel angle 4” x 6” x 5/16”, one required,

73-1/2” long which must span the top of the MAGNUM

Model 60 rebox opening.

This steel angle sits on top of the uppermost side

wall component with the four inch leg in the horizontal po-

sition. To avoid a thickness problem with the placement of

the steel angle it is necessary to cut a notch in the top Side

wall component where the angle is to sit. This notch should

be cut approximately 5/16” deep. The notch should start at

the front face of the side wall component (at both the left

and right hand walls) and run to a point 4” back toward the

rebox (Figure 30).

The steel angle sits in this notch. The six inch leg

of the steel angle is in the vertical position and is to be lo-

cated in alignment with the front of the rebox. The ends of

the steel angle should not protrude beyond the outer rebox

side walls (Figure 30).

Mortar between the steel and the notch in the top of the side

wall is not needed.

Step 7: Damper support (front & rear), Part M69, four

required, to be eld cut to t.

Bevel cut one end of each of two M69 damper sup-

ports to 35-1/2” in length from the long point of the bevel

cut to the un-cut square end. (Figure 31). The long point of

the bevel cut is to be at the top of the damper Support

For best results a 15˚ bevel angle is suggested.

Step 8: Bevel cut one end each of two M69 damper sup-

ports to 38” with the long point of the bevel at the bottom

of the damper support. The bevel angle must be at the same

angle – in this case, 15 degrees - to match with the bevel

angle of the other damper supports already cut in Step 7

(Figure 32).

Step 9: Set the cut damper supports along the front and

along the rear of the rebox using one of each of the cut

pieces (one with the long point at the top of the piece and

one with the long point at the bottom of the piece) together

as pairs.

The damper support pair at the front of the rebox

opening will be mortared together and set into the steel

angle from Step 6 (Figure 33).

Loading...

Loading...