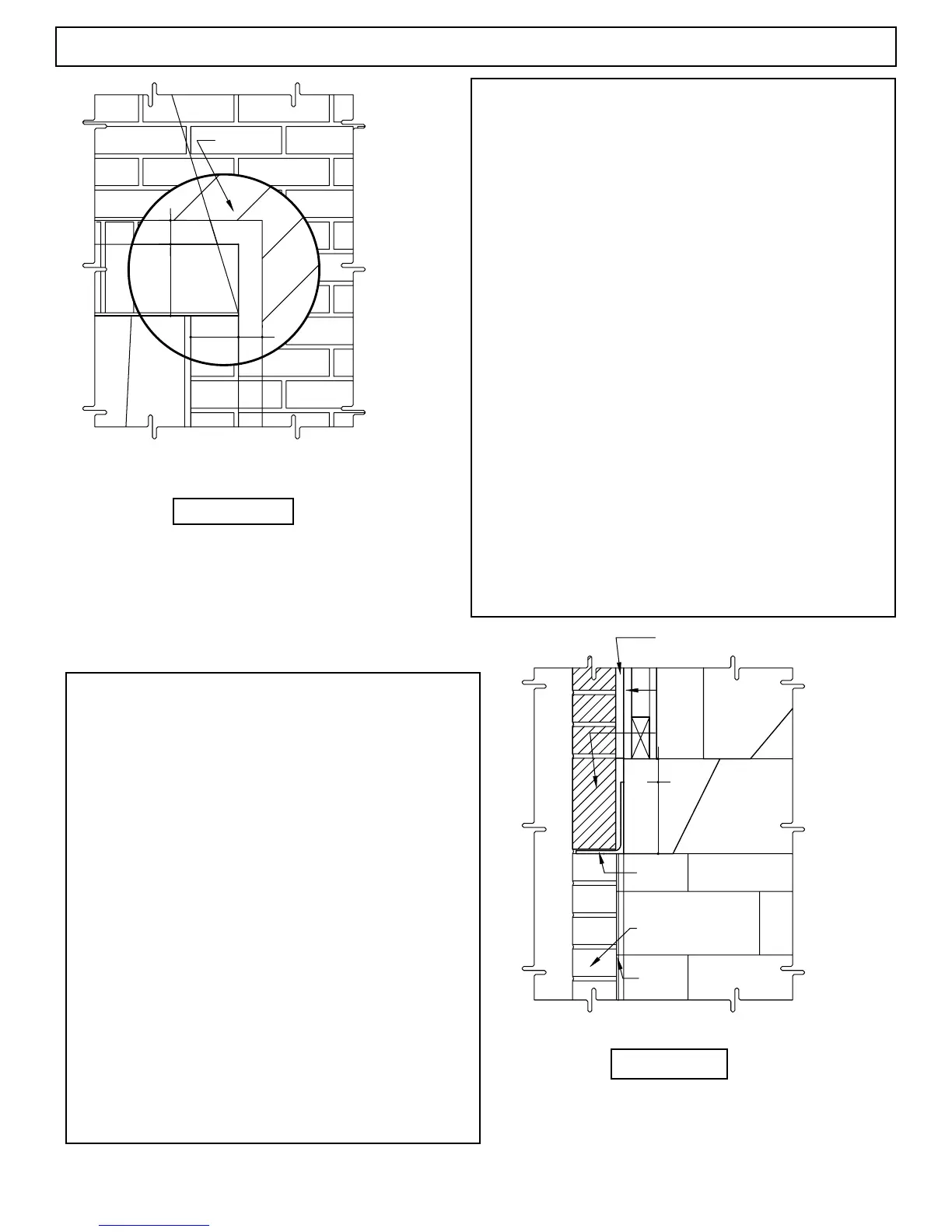

2"6"

4" 2"

BEARING

2"6"

WOOD (FLAMMABLE)

SHEATHING

MIN. CLEARANCE

MIN. CLEARANCE

BRICK

VENEER

WOOD (FLAMMABLE)

SHEATHING

MASONRY VENEER

4x6 STEEL L

MASONRY BEYOND

AIR SPACE

MORTAR JOINT

38

Masonry Veneer Construction Details

Brick, stone or other masonry veneer nished fronts to

MAGNUM replaces are possible. Special attention is required

with regards to:

(1) the placement of the proposed masonry

veneer facing and its interface with the MAGNUM re brick lin-

ing, and

(2) the masonry veneer and clearance to combustible framing and

sheathing from any steel “L” support used in the masonry veneer

around the front of the MAGNUM unit behind the veneer facing.

Any proposed brick, stone or other masonry veneer

facing must have sufcient foundation to support the full weight

of the veneer work. This may require review by a local structural

engineer prior to construction.

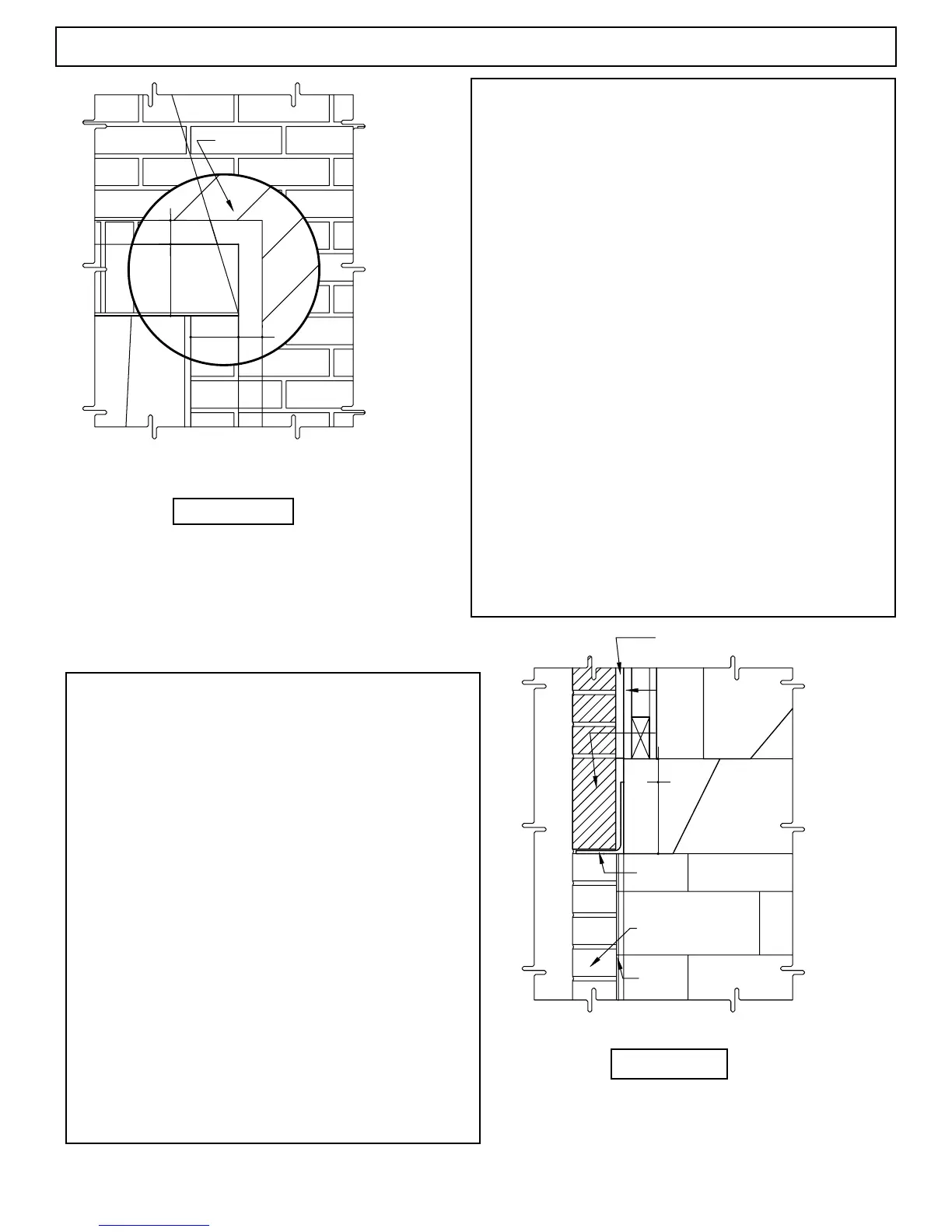

The veneer facing, when installed, must present a tight

seal with the leading edge - the room edge - of the MAGNUM

re brick lining at the sides of the MAGNUM rebox opening.

(Figure 83)

A steel “L” will need to span the top of the nished

replace opening to carry the masonry veneer as it spans over the

MAGNUM rebox opening. (Figures 80 & 81)

By code requirement this steel “L” must have a mini-

mum four inch (4”) end bearing. This bearing surface area shall

be provided in the veneer work. (Figure 80) It is important that

the steel “L” is set tight against the MAGNUM’s damper beam

front and set in a mud joint to avoid creating a “false chimney”

between the back of the steel “L” and the MAGNUM’s damper

beam front. (Figure 81)

Steel “L” or “angle” used to support masonry veneer

as it spans the MAGNUM’s rebox opening must, in all

cases, have a two inch (2”) minimum clearance to all combus-

tible materials. The vertical leg of the steel “L” cannot exceed

six inches (6”) in height.

Note: Properly placed combustible sheathing is kept a mini-

mum of eight inches (8”) away from the MAGNUM rebox

opening sides and top.

Important: Combustible framing members, normally set at

one and one-half inch (1-1/2”) clearance to the sides of the

MAGNUM rebox must be moved to at least two inch (2”)

clearance to the rebox sidewalls to maintain minimum two

inch (2”) clearance to the steel “L” to avoid a potential re

hazard.

Moving framing members two inches (2”) away

from the rebox side walls will maintain the minimum re-

quired two inch (2”) clearance from the steel “L” and, at the

same time allow full four inch (4”) end bearing required for

the steel “L”. (Figure 82)

FIGURE 81

FIGURE 80

Loading...

Loading...