Air bleeding from fuel (automatic air-bleeding system)

1. For the automatic air-bleeding system

When the starter switch is set to “OPERATION”, the

electromagnetic pump is activated to force-feed fuel

to the fuel pipe and the leak-off pipe, and air in the

fuel system is automatically bled.

2. For non-automatic air-bleeding system

While sending fuel by means of the force of the elec-

tromagnetic pump, the fall from the fuel tank or the

feed pump lever, bleed air out of the fuel pipe eye

bolt of the No. 1 cylinder injection pump, the leak-off

pipe eye bolt of the injection nozzle and the air-

bleeder plug of the fuel filter, starting with the one

installed the lower most and upward.

1. Operate the engine to warm-up until the coolant

temperature reachs to 75°C (167°F).

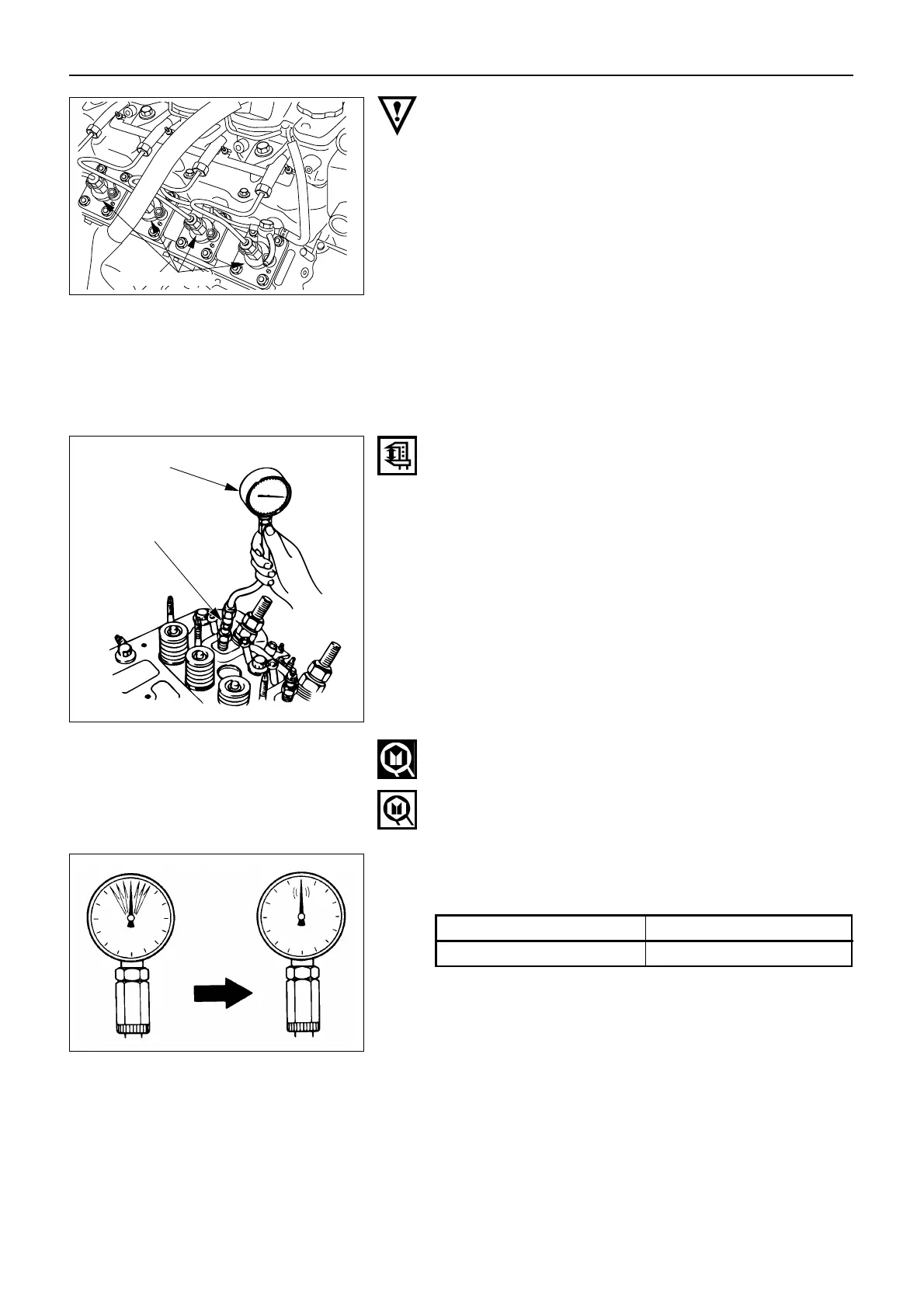

2. Remove all of the glow plugs and the injection

pipes.

3. Attach a compression gauge to the No. 1 cylinder

glow plug installation threads.

Note:

Compression pressure may be measured starting at any

cylinder and in no particular cylinder order. However, it

is very important that the compression pressure be

measured in each cylinder.

Therefore, start at the No. 1 cylinder and work back. In

this way, you will be sure to measure the compression

pressure in each cylinder.

Compression Gauge 5-8840-2675-0

Compression Gauge Adapter 5-8840-9029-0

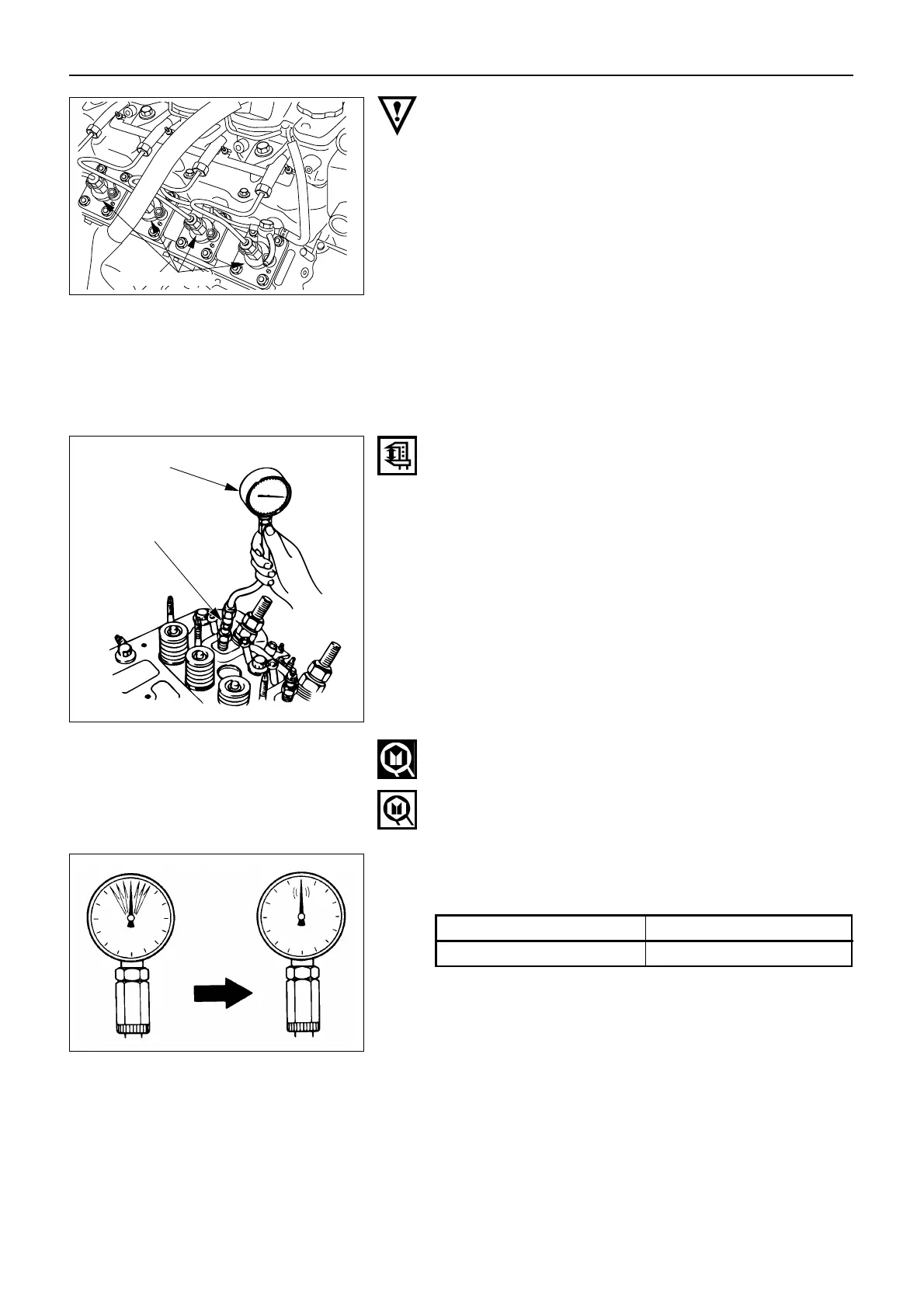

4. Crank the engine with the starter motor and take the

compression gauge reading.

MPa (kgf/cm

2

/psi) at 250 min

-1

Standard Limit

3 (31/440) 2.5 (26/370)

5. Repeat the procedure (.Steps 3 and 4.) for the

remaining cylinders.

Compression pressure should be approximately the

same for each cylinder. A variation exceeding 200

kPa (2.0 kg/cm

2

/.28 psi.) is unacceptable.

If the measured value exceeds the specified limit,

the related parts must be checked.

Loading...

Loading...