17

Model 763A Gage Pressure Transmitter Section 3

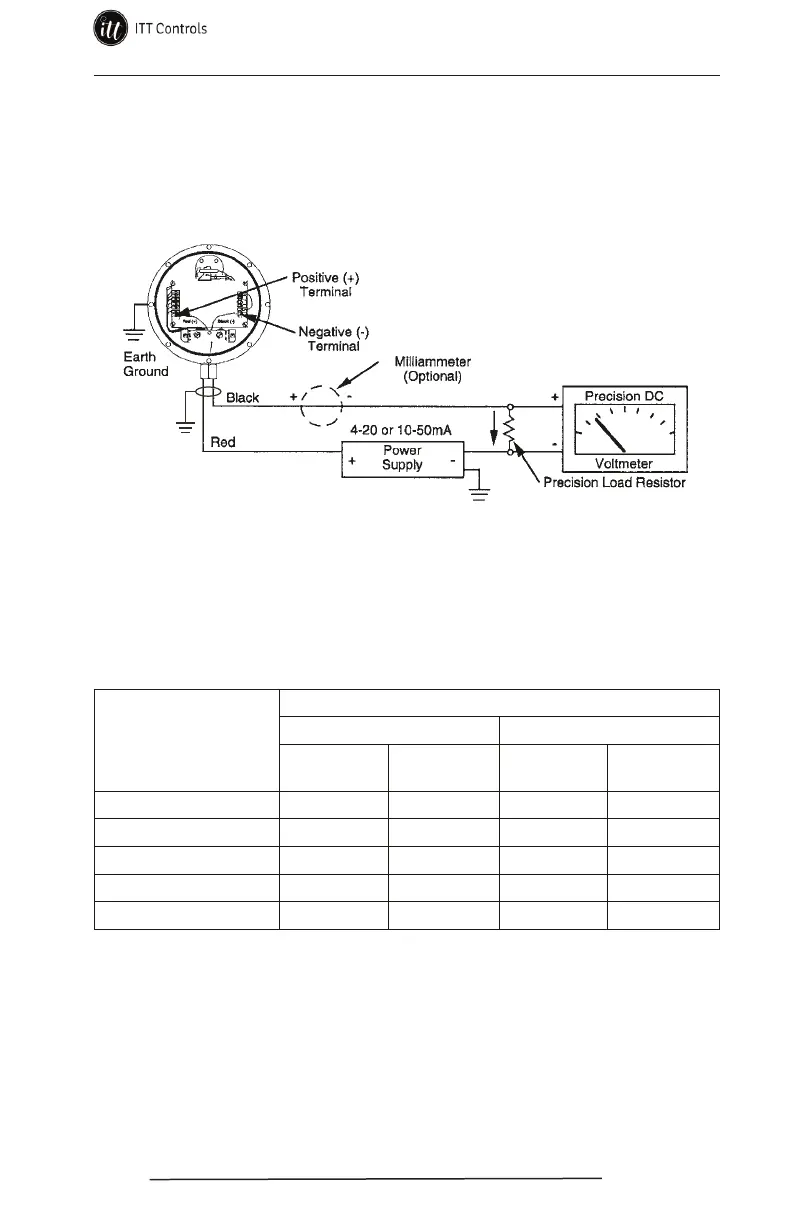

2. Connect the electrical readout device to the transmitter as shown in Fig-

ure 3.5 for either current or voltage readout. If the transmitter is equipped

to an EGS Quick Disconnect connector assembly, secure the two mating

connectors with the bayonet ring (see page 22 for details).

3. With minimum calibration pressure applied, check the output signal.

Figure 3.5—Electrical connections for calibration

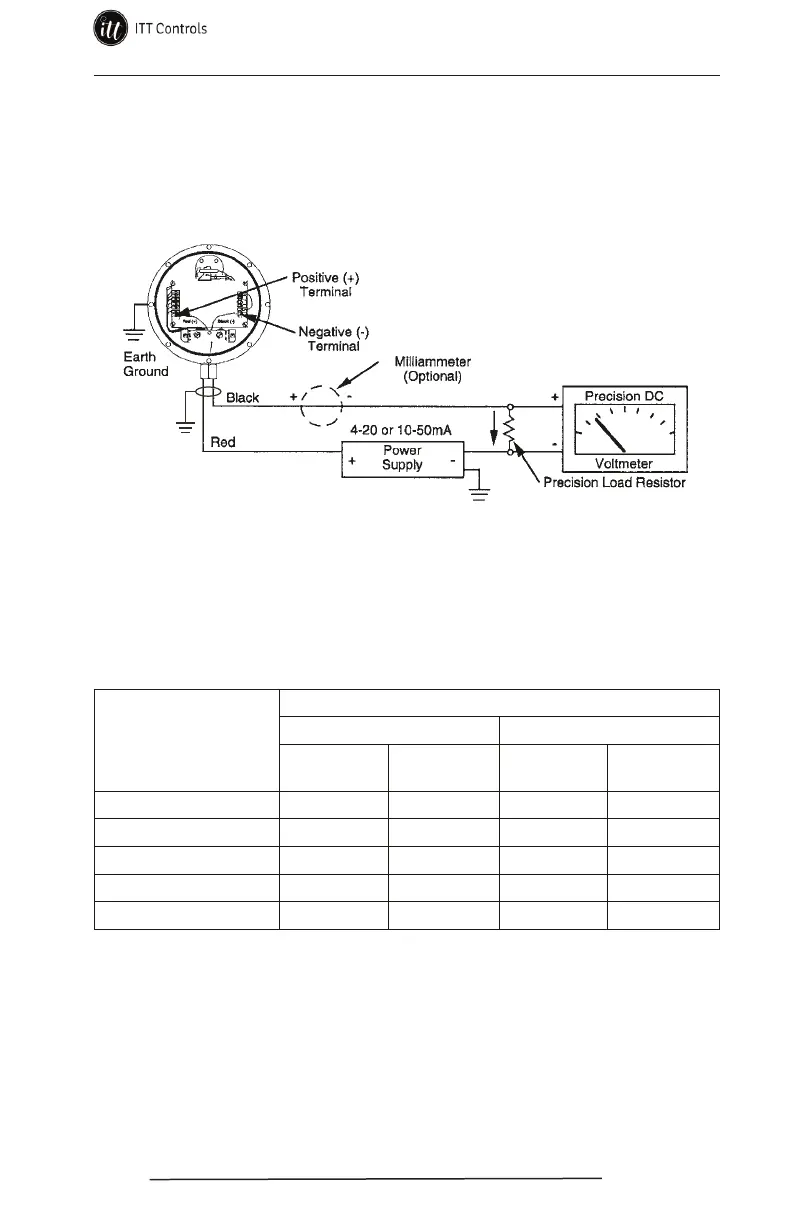

Table 3.1 presents the transmitter output values in current or voltage,

along with the associated tolerance, for both the 4-20 mA and 10-50 mA

variations. If the output signal is not the required reading, adjust the zero

control potentiometer in the compensating direction.

Table 3.1—Calibration Checkpoints

Applied Calibration

Pressure Checkpoint

(% of Full Scale)

Output*

4-20 mA Transmitter** 10-50 mA Transmitter***

Current

(±0.08 mA)

Voltage

(±0.04 Vdc)

Current

(±0.2 mA)

Voltage

(±0.04 Vdc)

0% 4 mA 2 Vdc 10 mA 2 Vdc

25% 8 mA 4 Vdc 20 mA 4 Vdc

50% 12 mA 6 Vdc 30 mA 6 Vdc

75% 16 mA 8 Vdc 40 mA 8 Vdc

100% 20 mA 10 Vdc 50 mA 10 Vdc

*This value includes the effects of conformance (non-linearity), deadband, hysteresis, and repeatability.

**This value was obtained using a 500-Ohm load resistor.

***This value was obtained using a 200-Ohm load resistor.

4. Apply calibration pressure corresponding to maximum output. If the

output signal is not the required reading per Table 3.1, adjust the span

control potentiometer in the compensating direction.

5. Zero and span controls have a minimum of interaction when adjusted;

however, steps 3 and 4 may be repeated as necessary to obtain desired

accuracy.

www.ittcontrols.com contact@ittcontrols.com

Loading...

Loading...