8/51

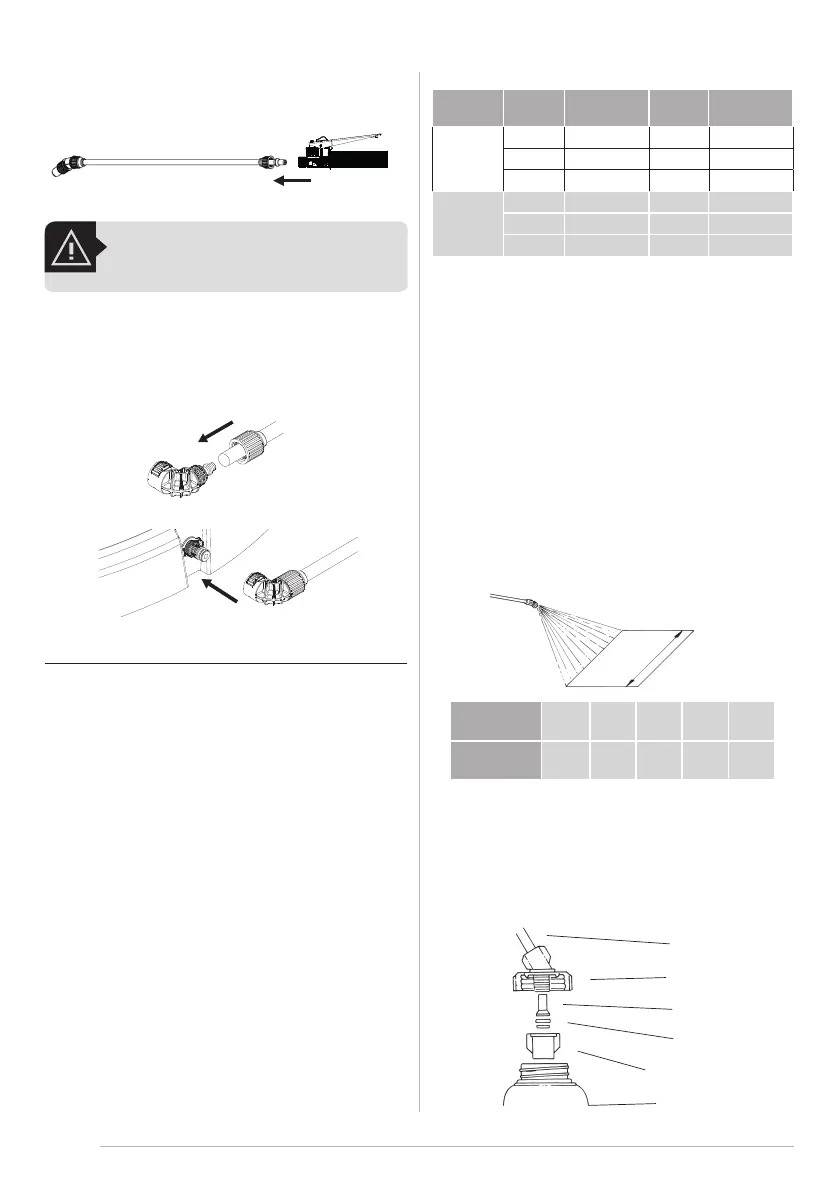

8.2. Assembling the lance to the trigger valve

Fit the lance into the trigger valve and thread enough so that there is no leakage,

as shown in the image below:

WARNING!

Do not overtighten the screw cap.

8.3. Assembling the hose to the sprayer

• Fit the hose through the S-20 nut, attach it to the connector and thread it.

• Plug the connector into the quick coupler and press until it clicks.

9. Operating Instructions

The following steps describe how to safely use the sprayer.

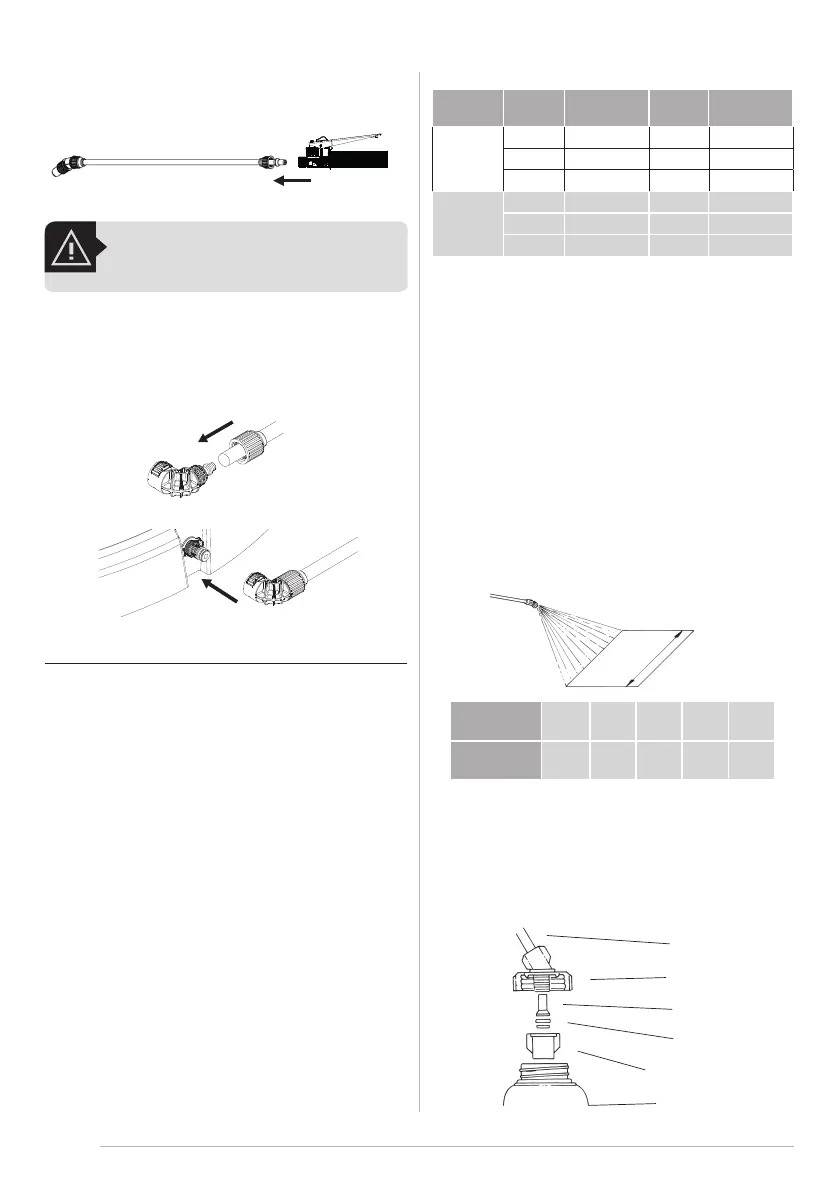

9.1. Choosing nozzle type

Three nozzles are supplied with the equipment. Each one is designed for a specic

use, according with the user need.

Pest Control nozzles:

• Blue adjustable cone nozzle - It allows the adjustment of the spray to ne

drops in the shape of a cone pattern and to a jet stream from short to long

distances (about 6 meters).

• JEF 8002 yellow nozzle - A uniform at fan nozzle with good application

range with an 80 ° opening angle, ne droplets for optimum coverage and a

ow rate of 0.8 L / min at 45 psi - ideal for perimeter and full area applications.

Disinfection nozzle:

• JEF 8001 orange nozzle - A uniform at fan nozzle with good application

range with an 80 ° opening angle, very ne droplets for optimal coverage and

ow rate of 0.4 L / min at 45 psi - ideal for indoor applications that require low

volume with excellent distribution.

9.3. Calibration of battery powered knapsack sprayer

PROCEDURE

1. USING CALIBRATOR BOTTLE (OPTIONAL)

2. Hold the lance at the working height and spray to measure the applica-

tion band width.

3. Based on the band width, calculate the total walking distance required to

spray the desired area. Use the chart as shown next.

Band

width

Lance

Cover

Filter

Nozzle

Nozzle cap

Calibrator

bottle

Attach the calibrator bottle to the lance as shown:

• Remove the cap, nozzle and lter.

• Mount the calibrator cover to the lance.

• Reinstall the lter, nozzle and cap.

• Screw the calibrator onto the cover.

Band width

(m)

0.5 0.7 1.0 1.2 1.5

Distance to

walk (m)

50.5 35.7 25.0 20.8 16.7

NOTE*: The values above may vary as to the wear, clogging and variation of the

nozzles, the density and viscosity of the liquid to be applied, the temperature and

relative humidity of the environment, the altitude and consequent atmospheric

pressure of the site, the height of the lance spraying, etc.

NOTE**: The minimum working nozzle pressure should always be observed, so

we do not recommend spraying at pressures below 15 psi for fan nozzles and

below 45 to 60 psi for conical nozzles depending on the model. In addition, we

do not recommend using ISO standard nozzles of brown color (05 gal/min at 3

bar pressure).

Nozzle Level Pressure (psi)

Flow rate

(L/min)

Autonomy

(h)

01

(ORANGE)

Min. 30 0,38 13,0

Med. 46 0,44 8,9

Max. 61 0,50 5,6

02

(YELLOW)

Min. 15 0,58 14,6

Med. 27 0,72 8,5

Max. 39 0,84 5,6

9.2. Pressure, flow rate and autonomy of each nozzle

type

Loading...

Loading...