Cables

Pulleys and cables need no lubri-

cant at any time.

L.P. Gas

System

DO NOT smoke while chang-

ing bottles or any lines.

DO NOT allow any connec-

tion to be loose.

DO NOT use ammonia or

chlorine based cleaners.

At the beginning of each season:

1. Inspect all gas lines for

crimps and road damage.

2. Check all lines and connec-

tions for leakage with soapy

water or leak detector.

3. We recommend that you

have the regulator checked

and adjusted to proper pres-

sure once a year. A gas leak

check should be performed

at least once a year by a

qualified technician.

Winch

The winch should be lubricated

once per year, preferably at the

season’s beginning. Use a small

quantity of light oil on two up-

per shaft bearings and also at each

end of main drum which cable

rolls on.

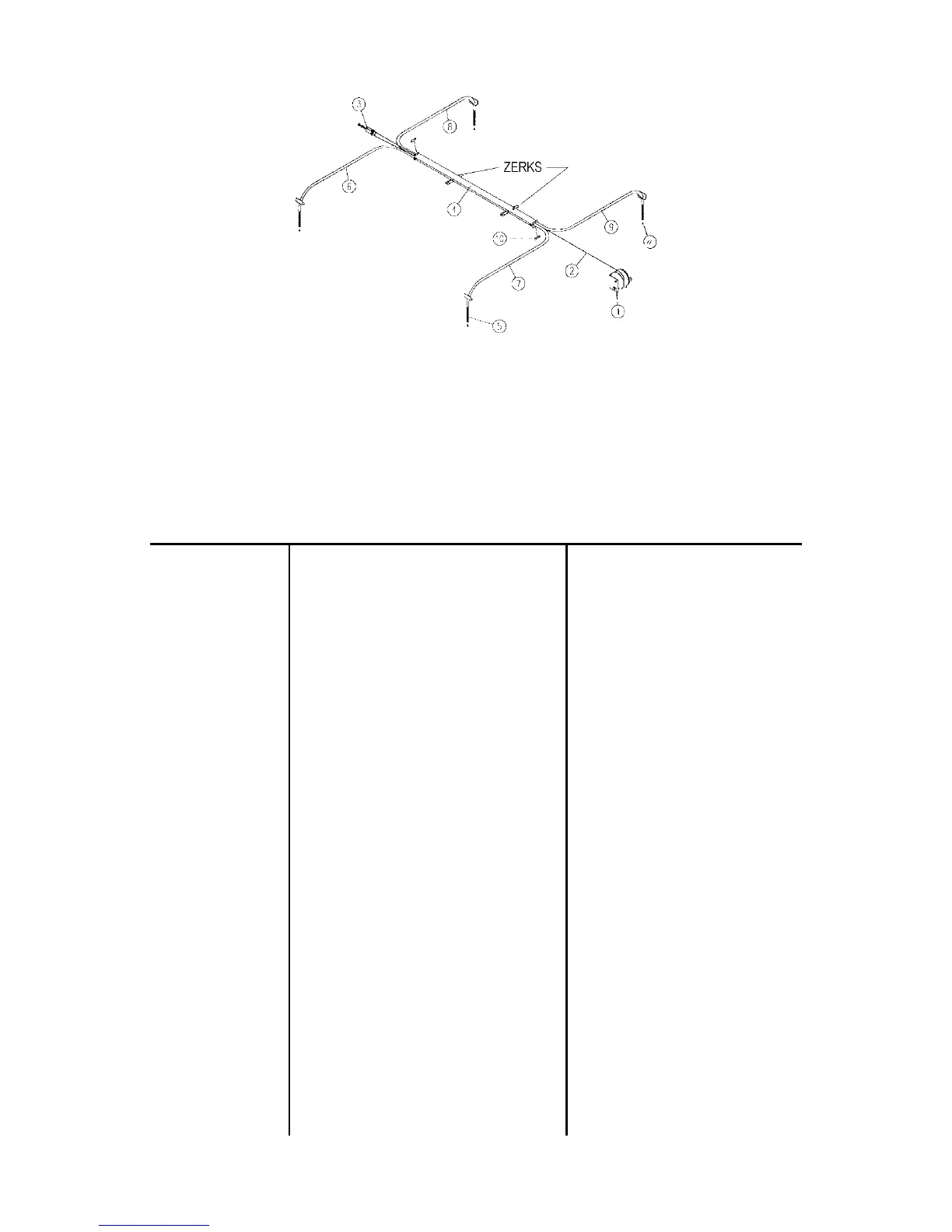

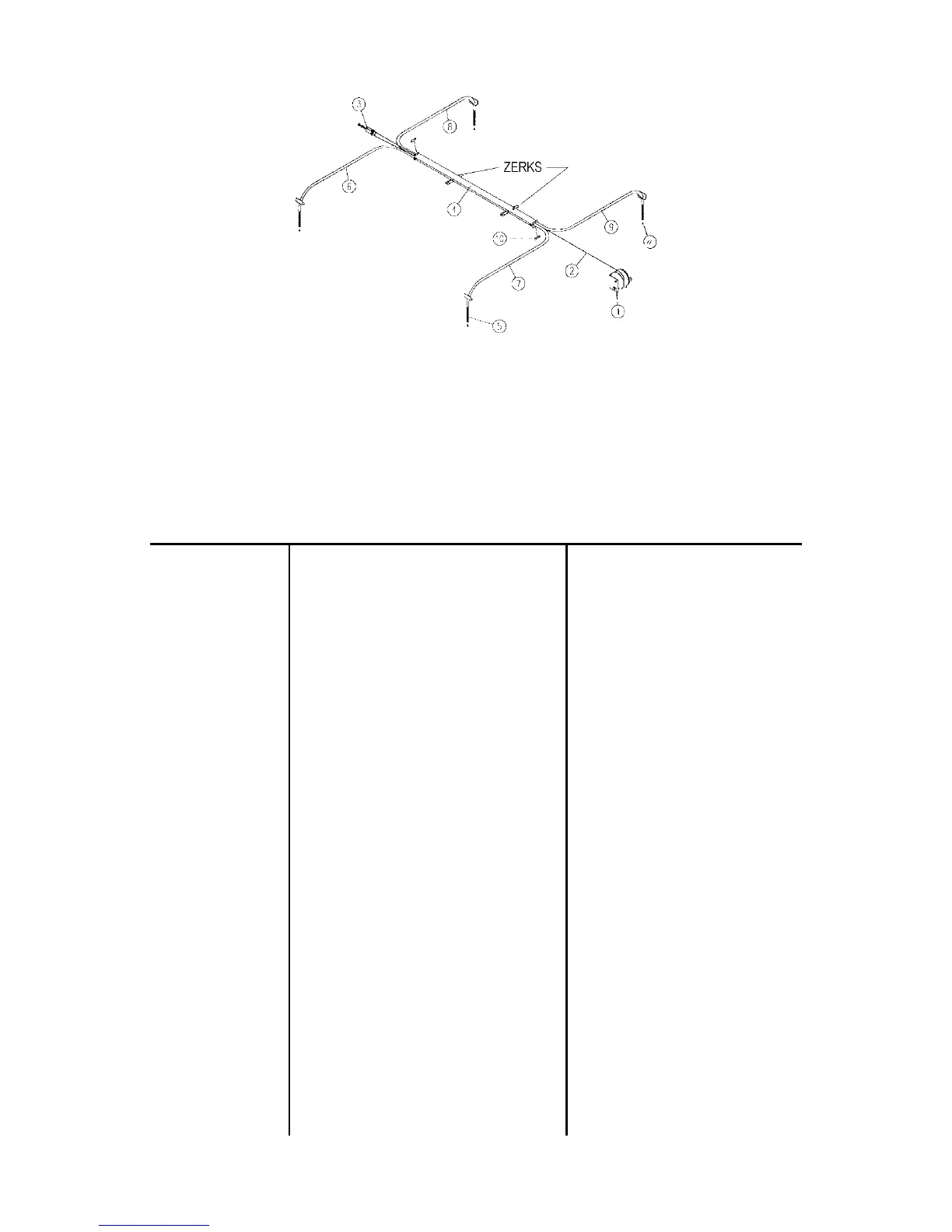

1 = WINCH DLB1200 6 = SPRING TUBE ASS'Y – ODS REAR

2 = CABLE ASSEMBLY 7 = SPRING TUBE ASS'Y – ODS FRONT

(8 QWEST - 184") (10 QWEST - 222") 8 = SPRING TUBE ASS'Y – DS REAR

3 = PULLEY ASSEMBLY 9 = SPRING TUBE ASS'Y – DS FRONT

4 = MASTER TUBE ASSEMBLY 10 = TIE BAR

5 = SPRING PUSH ROD 11 = 5/16 X 3/4 RIVET

(8 QWEST - 108") (10 QWEST - 110")

COMPONENT MAINTENANCE AVOID

66

Loading...

Loading...