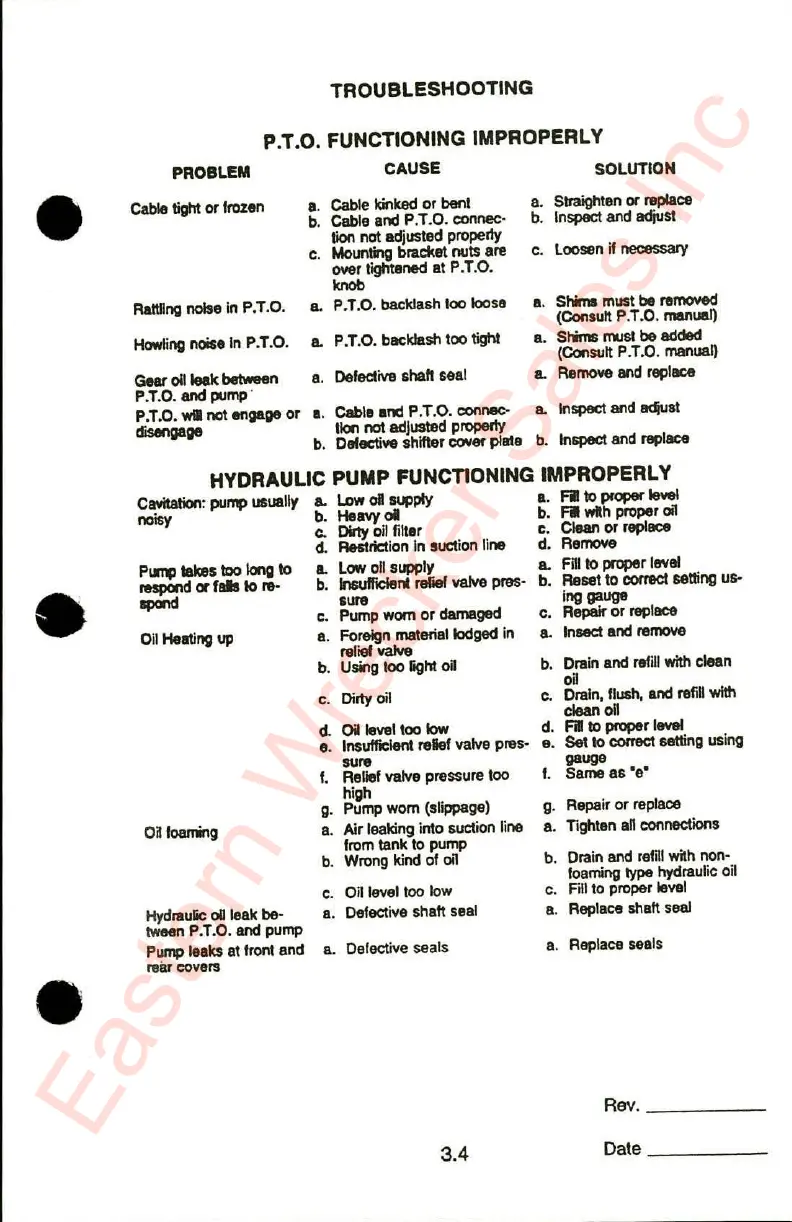

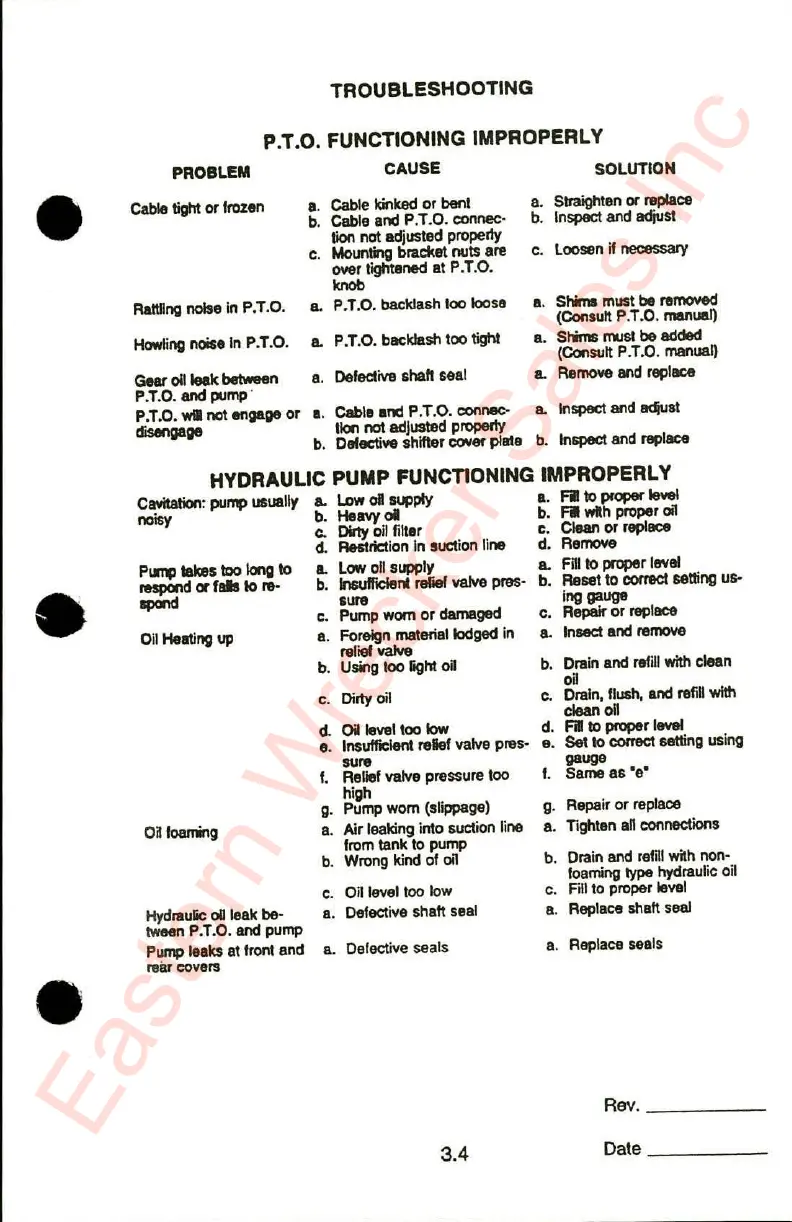

TROUBLESHOOTING

P.T.O. FUNCTIONING IMPROPERLY

PROBLEM

CAUSE

SOLUTION

•

cable tight or Irllzen

a. Cable kinked or bent

a

Straighten

or

replace

b. Coble em p.T.a. connec.

b. Inspect and adjust

lion not adjusted properly

c. Mounting bracket

,..,IS

are

c. loosen

if

necessary

over tightened at P.T.O.

knob

RaIlI1ngnoise In p.T.a.

a.

p.T.a.

backlash 100 klosa

II.

Shims must be

nll'ncwed

(COnsu~ p.T.a. manual)

Howling noise In p.T.a.

a. p.T.a. becklash too tight

a. ShBns ••• st be added

(ConSIJ~ p.T.a. manua~

Gear olIleak_

B. [)efed.ive shafl seal

a. Rel11OY9

and replace

P.T.a. al'<l pump.

P.T.O. wII not Oflgage or e. Coble em p.T.a. oonnec- a. Inspect and adjust

disengage lion not adjusted properly

b. Oefectill8 shtfter cover p1a1e b. inspect and

replace

HYDRAULIC PUMP FUNCTIONING IMPROPERLY

ClWitatlon: pump usually

a. Low oft supply

a. FiI to proper _

no;sy

b. Heavyol

b. FiI wIlh proper

",1

c. Dirty eil filter

C.

ChJan or reptace

d. Restriction In !Iuetion line

d. Remcwe

Pump _.

!DO

long to a. Low on supply

a. FlU10proper level

•

respond

Ol"

'sis

10 reo

b. _ ••• relief valve pres. b. ReGel to correcI selling u••

&pOnd

OUl1l

ing gauge

c. Pump worn or damaged

c. Repair or replace

Oil Heating up

8.

Foreign

materiBllodged in

a. Insect and remove

181;01_

b. Using too j;ght

col

b. Drain and

refill

with clean

oD

c. Dirty CHl

c. Oraln, tlush, end refiUwI1h

clean on

d.

OJ

level too low d. FII to proper level

e. InsufficIent relef valve pres- e. Set 10correct setting using

sure

gauge

f. Retlef vatve pressure 100

t.

Same as -e-

high

g. Pump worn (slippage)

g. Repair or replace

oa Ioening

a. Air leaking into suction line

a.

Tighten

an connections

from tank to pump

b. Wrong!clnd of

col

b. Drain and ratiOwith non.

toaming rype hydraulic o~

c. on level too low

c. Fin to proper level

HydI8Ulic olIleak be.

8.

Defective shaft seal

B. Replace shaft seal

tween P.T.a. al'<l pump

Pump leaks at front and

8.

Defective seals

a. Replace seals

reill' covers

•

Rev. _

3.4

OaI9 _

Eastern Wrecker Sales Inc

Loading...

Loading...