16

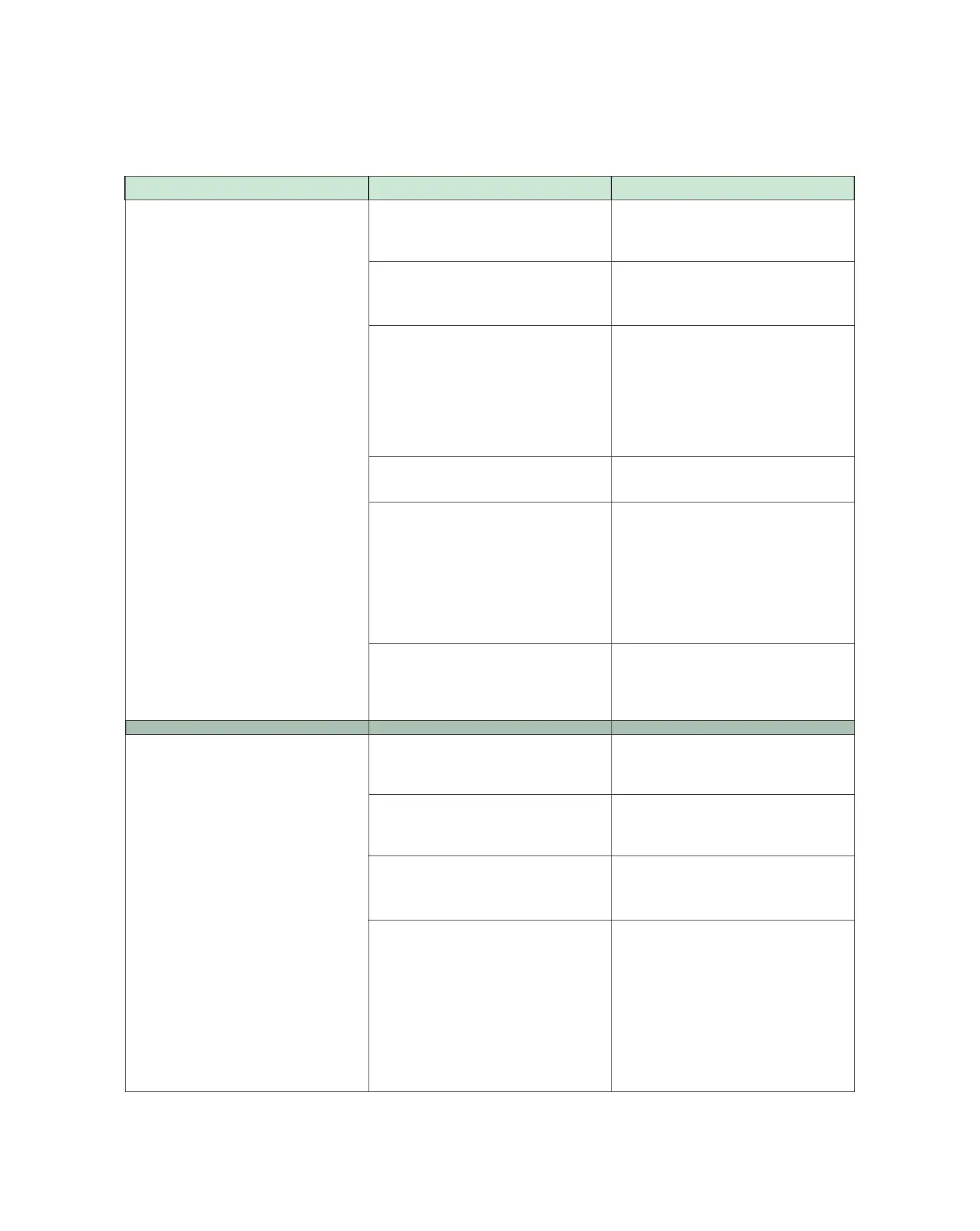

TROUBLESHOOTING

PROBLEM

CHECK

ACTION

Dishes are not clean

Verify that the scrap screens are clean.

Clean the scrap screens. Do not forget

the wash pump filter .

Detergent system may be blocked or

defective.

The detergent filter in the container

may be clogged. Rinse under water.

Check the detergent tube for deposits.

Clean the line if necessary. Peristaltic

hose(s) will have to be replaced

periodically as regular maintenance.

Check for cracks or leaks.

Verify the water level in the wash tank

correct.

Water level should be just under the

opening of the overflow pipe.

Check to see if the wash/rinse arm jets

are clogged.

Clean the jets/nozzles. Be careful not

to lose the o-rings.

Verify incoming water pressure.

The unit requires a minimum incoming

water pressure of 2 BAR. Check that

shut-offt valve fully opened. If incoming

pressure is still low, a pressure-booster

pump to increase the water pressure

may be required.

If the water pressure above 3 BAR, a

Pressure Reducing Valve must be

installed.

Missing Detergent

Replace the containers

Drain pump may be blocked or

defective.

Call for service. Food or debris in the

drain pump is not a warranty issue.

Incoming water pressure may be too

high.

Drain outlet hose may be kinked or

blocked.

Straighten or unblock hose.

If the water pressure above 3 BAR, a

Pressure Reducing Valve must be

installed.

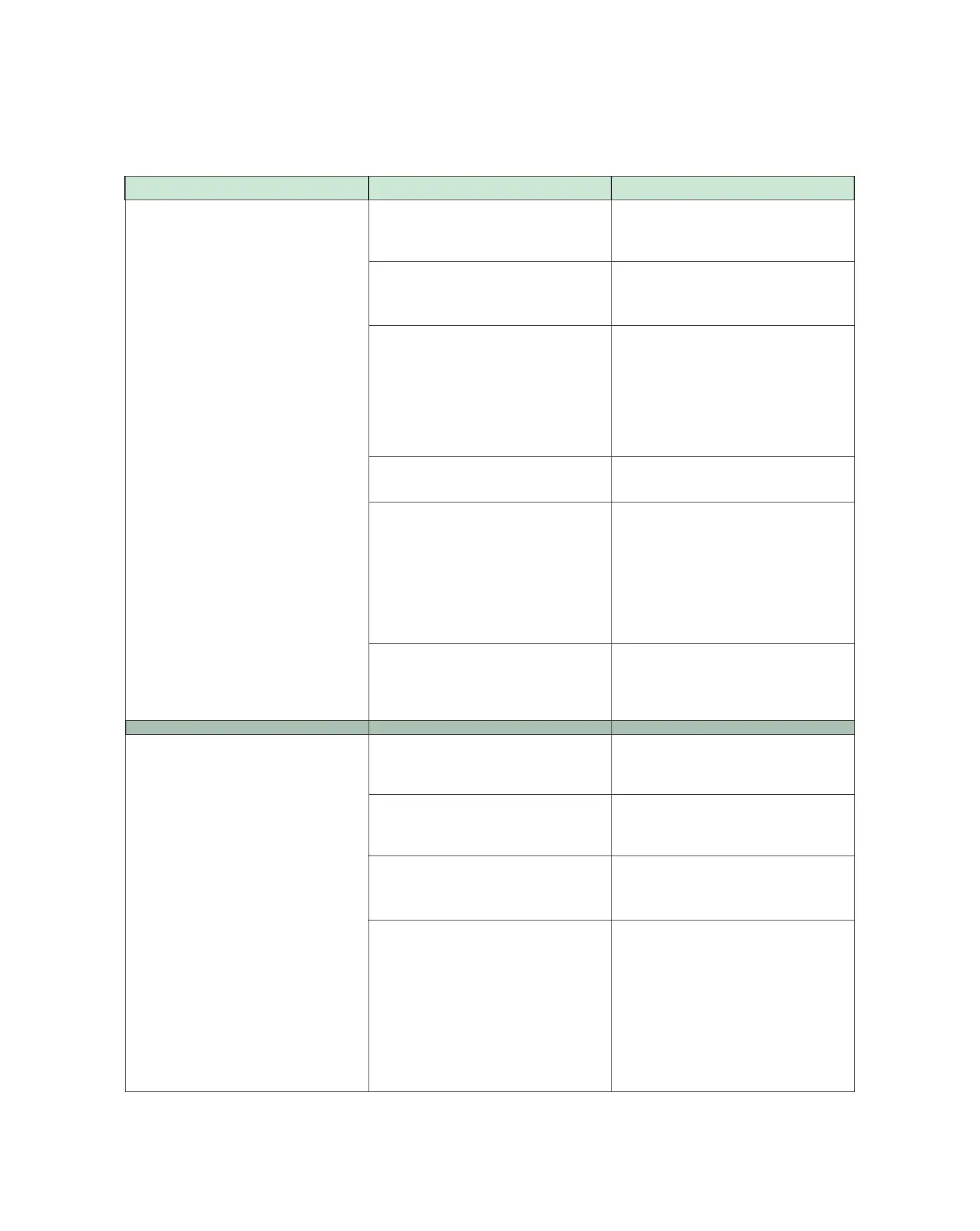

Warewasher overflows

Non-commercial foaming type

detergent may have been introduced

to the wash tank and is causing

excessive suds.

Turn off the washer and drain the

washtank. Remove as much suds as

possible. Do not replace overflow

pipe. Close the door and turn the

power on. Let unit run for 2 to 4

minutes. Turn off unit, replace

overflow pipe, close the door and

refill unit. Try washing. If the problem

reoccurs, repeat above procedure.

Loading...

Loading...