15. Stand sleeve on its base and slide seal assembly over sleeve until seal

faces touch.

16. Install lubricated O-ring into ID groove of sleeve adapter or pumping ring.

17. Slide sleeve adapter over sleeve, aligning pins of adapter with pins of

sleeve. Push down to engage “drive flats” until adapter stops at step

of sleeve.

18. Carefully slide snap ring over the end of sleeve. Using assembly tool,

push the snap ring in place inside the sleeve adapter until it snaps in

place. Be careful not to scratch the sleeve adapter.

19. Install lubricated O-ring into OD groove of outboard mating ring.

20. Slide mating ring over sleeve, align pins and press in place.

21. Install lubricated O-ring into OD groove of outboard retainer.

22. Place spring inside retainer.

23. Insert drive ring in retainer with tabs facing opposite of spring. Align

notches with dents in retainer.

24. Insert anti X-ring in retainer.

25. Install lubricated O-ring on the primary ring. Push down until seated on

the step of the OD of primary ring.

26. Align notches on primary ring tail with drive ring tabs and press into bore

of retainer. Make sure primary ring is engaged into tabs and moves freely.

27. Place gland plate onto table with O-ring side up.

28. Insert seal assembly in gland plate, align pins and press in place. Turn

gland plate over and confirm that retainer is flush with end of gland plate.

29. Clean faces of primary and mating rings with denatured alcohol and a

lint-free cloth.

30. Insert O-ring in face groove of gland plate.

31. Making sure seal face does not fall out, slide gland plate over sleeve

until seal faces touch.

32. Carefully rotate gland plate until holes in sleeve are lined up with the

collar set screws.

33. Carefully press down on gland plate and install snap ring over the end

of sleeve. Do not over compress gland plate or this may damage

the seal.

34. Tighten set screws until they start to enter the sleeve ID.

35. Uniformly tighten cap screws on spacers.

36. Install gasket and sleeve O-ring.

37. Pressure test according to John Crane standard QA-5-0569.

38. Plug gland pipe taps as noted with metal plugs provided.

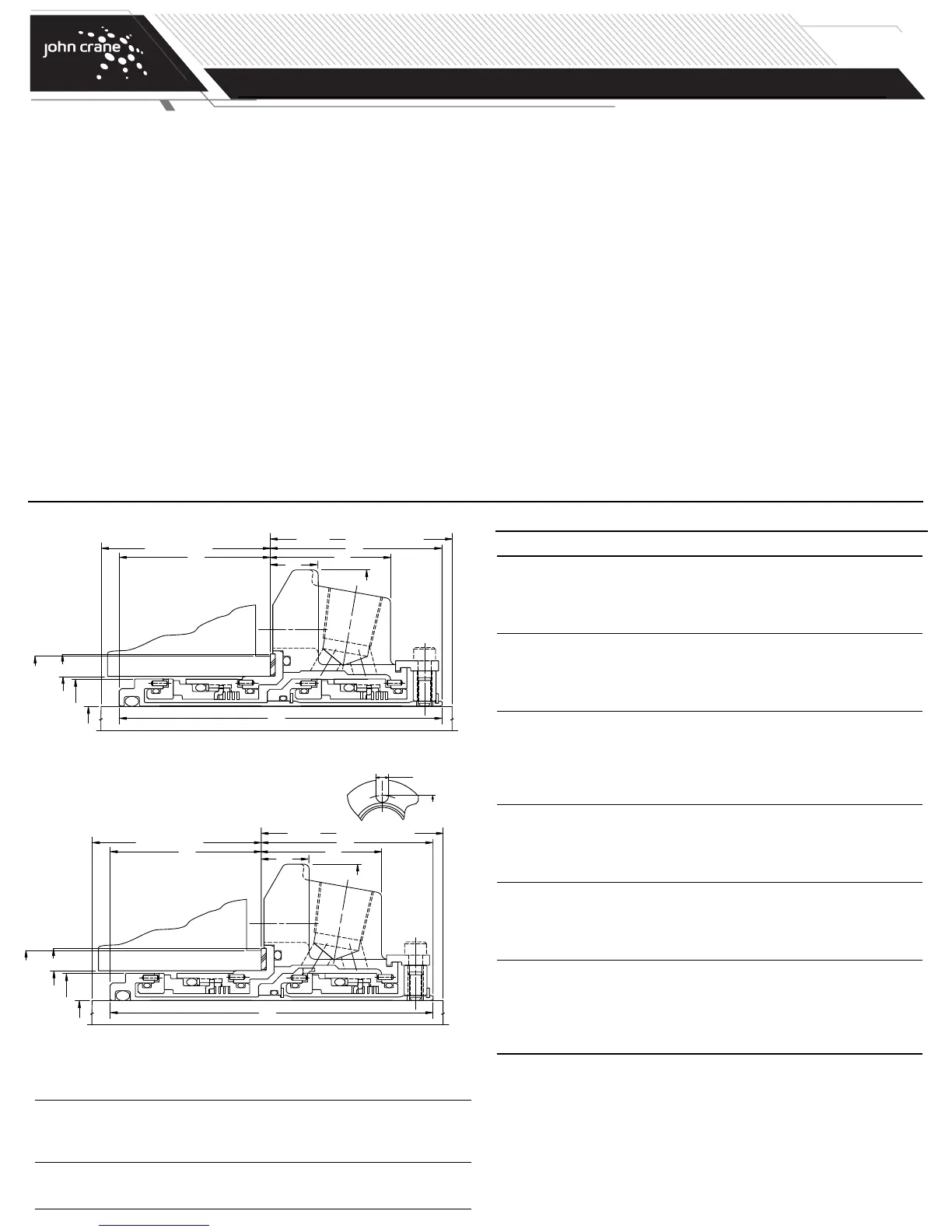

Type 5620 Installation Dimensions

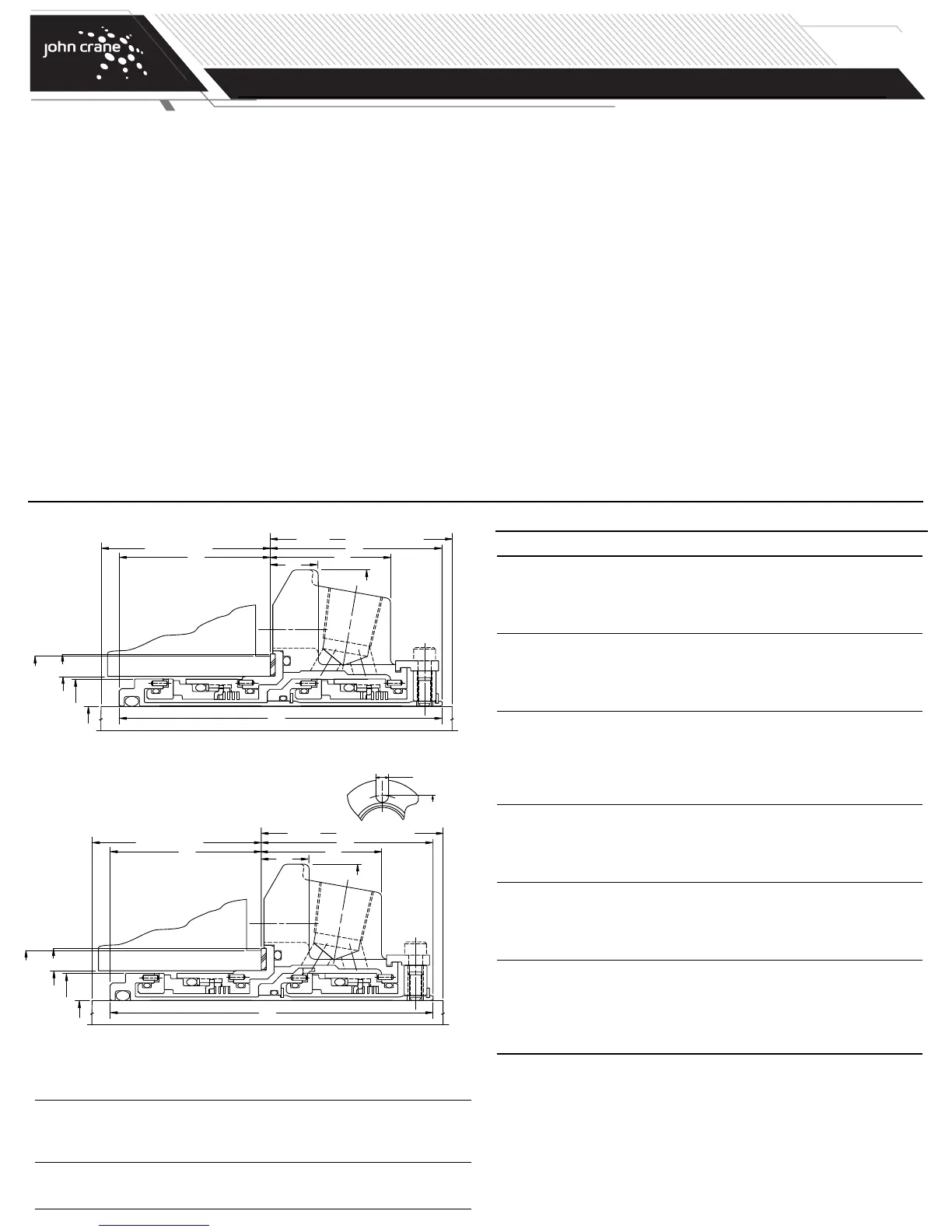

Type 5620P Installation Dimensions

1.000 1.564 1.625 1.889 4.000 3.705 1.353 1.954 0.531 2.000 1.876 1.751 0.525 2.805

1.125 1.689 1.750 2.015 4.125 3.851 1.446 2.062 0.531 2.125 1.914 1.789 0.525 2.933

1

.250 1.812 1.875 2.294 4.250 3.851 1.446 2.062 0.531 2.125 1.914 1.789 0.525 3.213

1.375 1.939 2.000 2.421 4.375 3.851 1.446 2.062 0.531 2.125 1.914 1.789 0.525 3.338

1.500 2.187 2.250 2.680 4.875 3.995 1.487 2.125 0.593 2.187 1.995 1.870 0.525 3.599

1.625 2.312 2.375 2.812 5.000 3.995 1.487 2.125 0.593 2.187 1.995 1.870 0.562 3.766

1.750 2.406 2.480 2.918 5.250 3.995 1.487 2.125 0.593 2.187 1.995 1.870 0.563 3.875

1.875 2.549 2.625 2.918 5.250 3.995 1.487 2.125 0.593 2.187 1.995 1.870 0.563 3.875

2.000 2.673 2.750 3.015 5.500 4.355 1.601 2.312 1.063 2.375 2.167 2.042 0.562 4.000

2.125 2.798 2.875 3.360 5.859 4.355 1.601 2.313 0.593 2.375 2.167 2.042 0.687 4.469

2.250 2.923 3.000 3.485 6.500 4.355 1.601 2.312 0.593 2.375 2.167 2.042 0.687 4.566

2.375 3.048 3.125 3.610 6.500 4.545 1.717 2.466 0.625 2.825 2.204 2.079 0.687 4.719

2.500 3.301 3.375 3.891 6.750 4.545 1.717 2.563 0.625 2.625 2.107 1.982 0.687 5.000

2.625 3.551 3.625 4.062 6.750 4.594 1.625 2.500 0.625 2.562 2.219 2.094 0.687 5.170

2.750 3.551 3.625 4.062 6.750 4.594 1.625 2.500 0.625 2.562 2.219 2.094 0.687 5.170

2.875 3.614 3.750 4.186 7.000 4.594 1.725 2.500 0.625 2.562 2.219 2.094 0.687 5.312

3.000 3.864 4.000 4.469 7.750 4.594 1.787 2.562 0.685 2.625 2.157 2.032 0.812 5.720

3.125 4.022 4.125 4.600 7.875 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 5.845

3.250 4.022 4.134 4.600 7.437 4.687 1.593 2.510 N/A 2.635 2.302 2.177 0.812 5.845

3.375 4.246 4.375 4.850 8.125 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 6.095

3.500 4.371 4.500 4.975 8.250 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 6.220

3.625 4.500 4.625 5.100 8.375 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.687 6.250

3.750 4.625 4.724 5.199 8.750 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.687 6.770

3.875 4.750 4.875 5.375 8.750 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 6.636

4.000 4.875 5.000 5.500 9.000 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 6.761

4.125 5.000 5.125 5.625 9.000 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 6.886

4.250 5.125 5.250 5.750 9.250 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 7.011

4.500 5.375 5.500 6.000 9.500 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 7.261

4.750 5.625 5.750 6.313 10.375 4.687 1.593 2.562 N/A 2.687 2.250 2.125 0.812 7.574

5.000 6.125 6.760 7.260 12.000 5.515 1.749 3.043 N/A 3.168 2.598 2.473 0.812 10.000

5.250 6.375 7.010 7.510 12.250 5.515 1.749 3.043 N/A 3.168 2.598 2.473 0.812 10.250

5.500 6.625 7.500 8.000 12.687 5.515 1.749 3.043 N/A 3.168 2.598 2.473 0.937 10.500

L39L91 MIN. BOX DEPTH

L92

L90 MIN. NEAREST OBSTRUCTION

D3

L56

D26

D4

D1 +.000"

-.002"

D30

*

MIN.

TURN

DIAM.

L12

L23

L39L91 MIN. BOX DEPTH

L92

L90 MIN. NEAREST OBSTRUCTION

D3

L56

D26

D4

D1 +.000"

-.002"

D30

*MIN.

TURN

DIAM.

L12

L23

Type 5620/5620P Dual Cartridge Dimensional Data (inches)

Seal D4

Size/D1 D3 Min. Max. D26 L12 L23 L39 L56 L90 L91 L92 M N

Type 5620 Dual O-Ring Cartridge Seal Assembly (cont.)

*Oversize bore seals only

*Oversize bore seals only

Type 5620/5620P Oversize Bore Dual Cartridge

Dimensional Data (inches)

Seal D4 Min.

Size/D1 D3 Min. Max. D26 L12 L23 L39 L56 L90 L91 L92 M N Turn Diam.

1.375 1.939 2.875 3.023 5.375 3.851 1.446 2.062 0.625 2.125 1.914 1.789 0.562 4.062 3.268

1.750 2.406 3.500 3.925 6.500 3.995 1.487 2.125 0.656 2.187 1.995 1.870 0.687 5.093 3.885

1.875 2.549 3.625 3.734 6.500 3.995 1.487 2.125 0.656 2.187 1.995 1.870 0.687 5.093 4.006

2.125 2.798 3.875 4.250 7.250 4.355 1.570 2.282 0.749 2.407 2.198 2.073 0.687 5.687 4.264

2.500 3.301 4.750 5.078 8.000 4.545 1.788 2.563 0.749 2.625 2.107 1.982 0.687 6.062 5.000

2.625 3.551 4.625 4.740 8.000 4.594 1.788 2.500 0.749 2.562 2.219 2.094 0.687 6.062 5.000

2.750 3.551 4.750 4.875 8.000 4.594 1.697 2.407 0.656 2.532 2.312 2.187 0.687 6.062 5.139

TYPE 5620/5620P

DUAL O-RING CARTRIDGE SEAL

Installation, Operation & Maintenance Instructions

PAGE

3

Loading...

Loading...