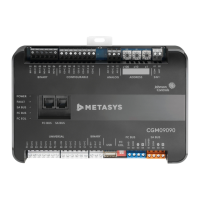

Metasys System FEC1611 and FEC1621 Field

Equipment Controller Installation Guide

Application

The FEC16 Field Equipment Controller (FEC) is part of

the Metasys

®

system Field Equipment Controller family.

The FEC16 controller runs pre-engineered and user-

programmed applications and provides the inputs and

outputs required to monitor and control a wide variety of

HVAC equipment.

The FEC controllers can communicate using either BACnet

MS/TP or N2 communications protocols. These controllers

used as MS/TP devices operate on an RS-485 BACnet

®

MS/TP Bus as BACnet Application Specific Controllers (B-

ASC) and integrate into Johnson Controls

®

and third-party

BACnet systems.

With Release 10.1, you can use the Controller

Configuration Tool (CCT) 13.0 and later software to switch

the FEC to use the N2 protocol.

The FEC16 controller is available with or without an

integral LCD and push-button user interface.

Communications protocol

The Metasys

®

system FEC Family Controllers and network

sensors communicate using either the standard BACnet

protocol, based on the ANSI/ASHRAE 135-2008, or the

BACnet/IP protocol. The BACnet protocol is a standard

for ANSI, ASHRAE, and the International Standards

Organization (ISO) for building controls.

FEC, VMA16, VMA18, and most IOM field controllers are

BTL-listed as BACnet Application Specific Controllers

(B-ASCs). FAC field controllers and the VMA1930 Field

Controller are BTL-listed as BACnet Advanced Application

Controllers (B-AACs).

Release10.1 and later of the Controller Configuration Tool

(CCT) can be used to switch Field Bus communications

protocol in supported FAC, FEC, and VMA controllers to be

either the standard BACnet MS/TP or the N2 protocol. All

new controllers use either BACnet MS/TP as the default

communications protocol, or BACnet/IP. Switchable

communications protocols in the MS/TP models provide

a cost-effective upgrade and modernization path for

customers with existing N2 controllers.

North American emissions compliance

United States

This equipment has been tested and found to comply with

the limits for a Class A digital device pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

this equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area may cause harmful

interference, in which case the users will be required to

correct the interference at their own expense.

Canada

This Class (A) digital apparatus meets all the requirements

of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la Classe (A) respecte toutes

les exigences du Règlement sur le matériel brouilleur du

Canada.

Installation

Observe these guidelines when installing a field controller:

• Transport the controller in the original container to

minimize vibration and shock damage.

• Verify that all parts shipped with the controller.

• Do not drop the controller or subject it to physical

shock.

Parts included

• One field controller with removable terminal blocks

• One installation instructions sheet

Materials and special tools needed

• Three fasteners appropriate for the mounting surface

(M4 screws or #8 screws)

• One 20 cm (8 in.) or longer piece of 35 mm DIN rail and

appropriate hardware for DIN rail mount (only)

• Small straight-blade screwdriver for securing wires in

the terminal blocks

Mounting

Observe these guidelines when mounting a field

controller:

• Ensure the mounting surface can support the

controller, DIN rail, and any user-supplied enclosure.

• Mount the controller horizontally on 35 mm DIN rail

whenever possible.

• Mount the controller in the proper mounting position

(Figure 1).

• Mount the controller on a hard, even surface whenever

possible in wall-mount applications.

• Use shims or washers to mount the controller securely

and evenly on the mounting surface.

• Mount the controller in an area free of corrosive vapors

and observe the Ambient Conditions requirements in

Table 10.

*2410143136N*

Part No. 24-10143-136 Rev. N

2019-10-18

(barcode for factory use only)

MS-FEC1611-1, MS-FEC1621-1, MS-

FEC1611-1ET