TFP1581

Page 6 of 14

Technical

Data

Approvals

UL and C-UL Listed (2 in. to 6 in. only)

FM Approved

The UL Listing is based on the following

factors:

• Installation requirements referenced in

the Standard for Installation of Sprinkler

Systems, NFPA 13, or the Standard

for Installation of Standpipe and Hose

Valves, NFPA 14, as applicable.

• Inspection, testing, and maintenance

requirements referenced in the

Standard for Inspection, Testing, and

Maintenance of Water-Based Fire

Protection Systems, NFPA 25.

• Filed-setting of the Model PRV-1

A Valve

to provide required outlet pressures and

flows for the given application.

• Testing of the Model PRV-1A Valve after

installation in accordance with NFPA 13

and/or NFPA 14 as applicable.

• Testing the Model PRV-1A Valve

periodically thereafter in accordance

with NFPA 25.

Note: UL/C-UL Approval is based on the

use of the 3/4 in. CLA-VAL Model 55L-60

pressure relief valve.

Maximum Inlet Pressure

300 psi (20,7 bar)

Factory Outlet “Set Pressure”

125 psi (8,6 bar)

Field Outlet “Set Pressure” Range

90 to 175 psi (6,2 to 12 bar)*

* = Sizes 2, 3, 6 and 8 in. are rated to a set pres-

sure of 80 to 175 psi (5,5 to 12 bar)

Pressure Loss With Inlet Pressure

Above “Set Pressure”

The inlet pressure minus the outlet “set

pressure” equals pressure loss. For

example, assuming that the inlet flowing

pressure is 225 psi (15,5 bar) and the field

outlet “set pressure” is 130 psi (9,0 bar),

the pressure loss is 95 psi (6,5 bar).

Pressure Loss with Inlet Pressure

Below “Set Pressure”

See Graphs A to E. These graphs are a

requirement of UL and should be used as

reference only.

Rated Flowing Range

2 in. .................. 25 to 250 gpm

(DN50) ............... (95 to 946 Lpm)

3 in. .................. 25 to 500 gpm

(DN80) ..............(95 to 1893 Lpm)

4 in. ................. 25 to 1000 gpm

(DN100) .............(95 to 3785 Lpm)

6 in. ................. 25 to 1300 gpm

(DN150 ) .............(95 to 4920 Lpm)

8 in. ................100 to 4000 gpm

(DN200) ............(379 to 15141 Lpm)

Note: Rated flowing range is the flow range

tested by the approval agencies. All valves

are leak tight and are capable of operating

at 0 gpm (0 Lpm).

End Connections

• Flanged end connections are available

as drilled per Table A.

• Grooved end connections follow

industry standard groove specifications.

Valve Materials of Construction

See Figure 3

Body

Epoxy-coated ductile iron per ASTM

A536-77, Grade 65-45-12

Diaphragm Cover

Epoxy coated ductile iron per ASTM

A536-77, Grade 65-45-12

Diaphragm

Polyester fabric-reinforced, TEFLON

coated, EPDM rubber per ASTM D2000

Diaphragm Cover Fasteners

Aluminium-zinc coated steel

Trim Materials of Construction

See Figure 7

Pilot Valve

Cast bronze and stainless steel with fabric

reinforced, EPDM rubber per ASTM D2000

diaphragm

Pressure Gauges

3 3/4 in. (95 mm) diameter, UL and FM

listed, 0 to 300 psi (0 to 20,7 bar)

Strainer, Tube, and Fittings

Stainless steel

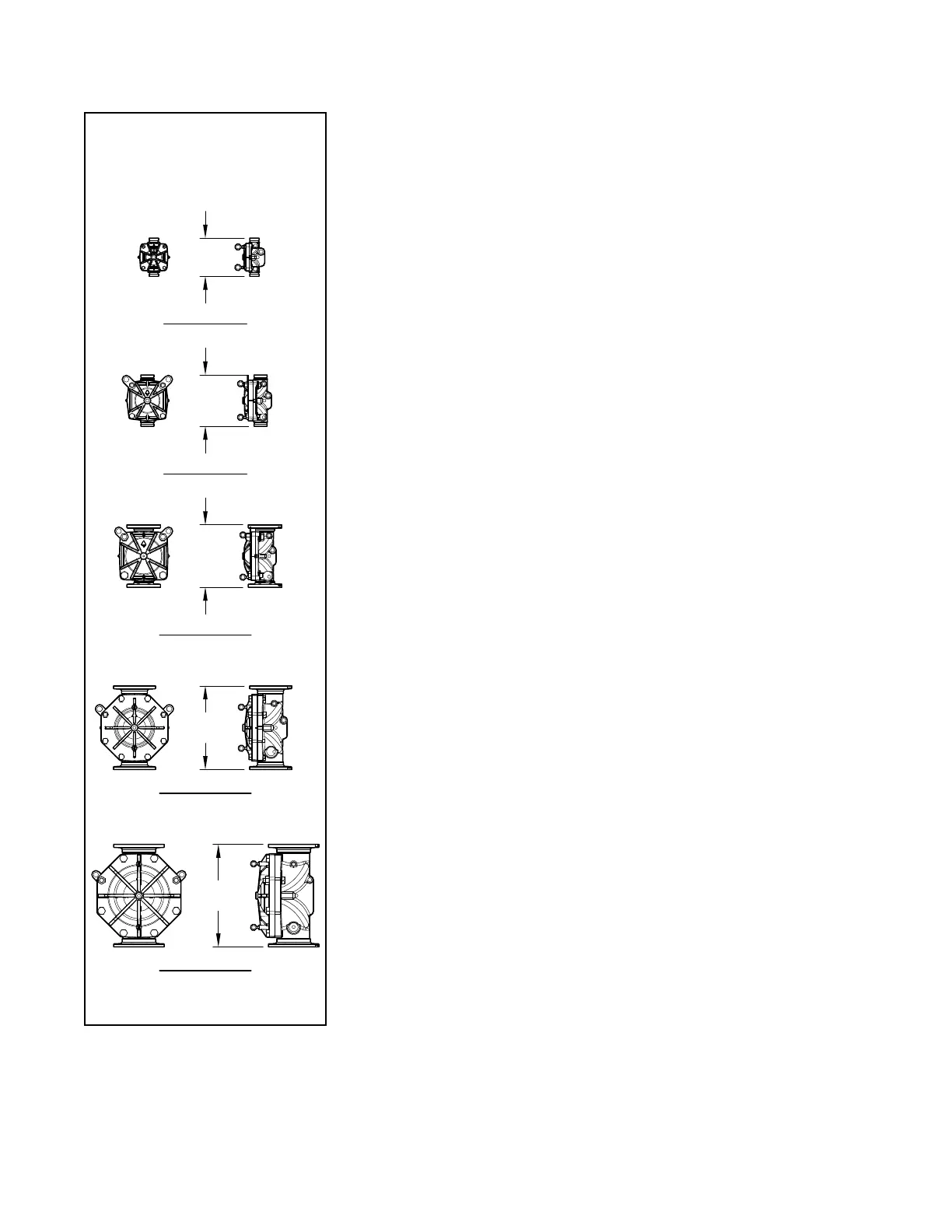

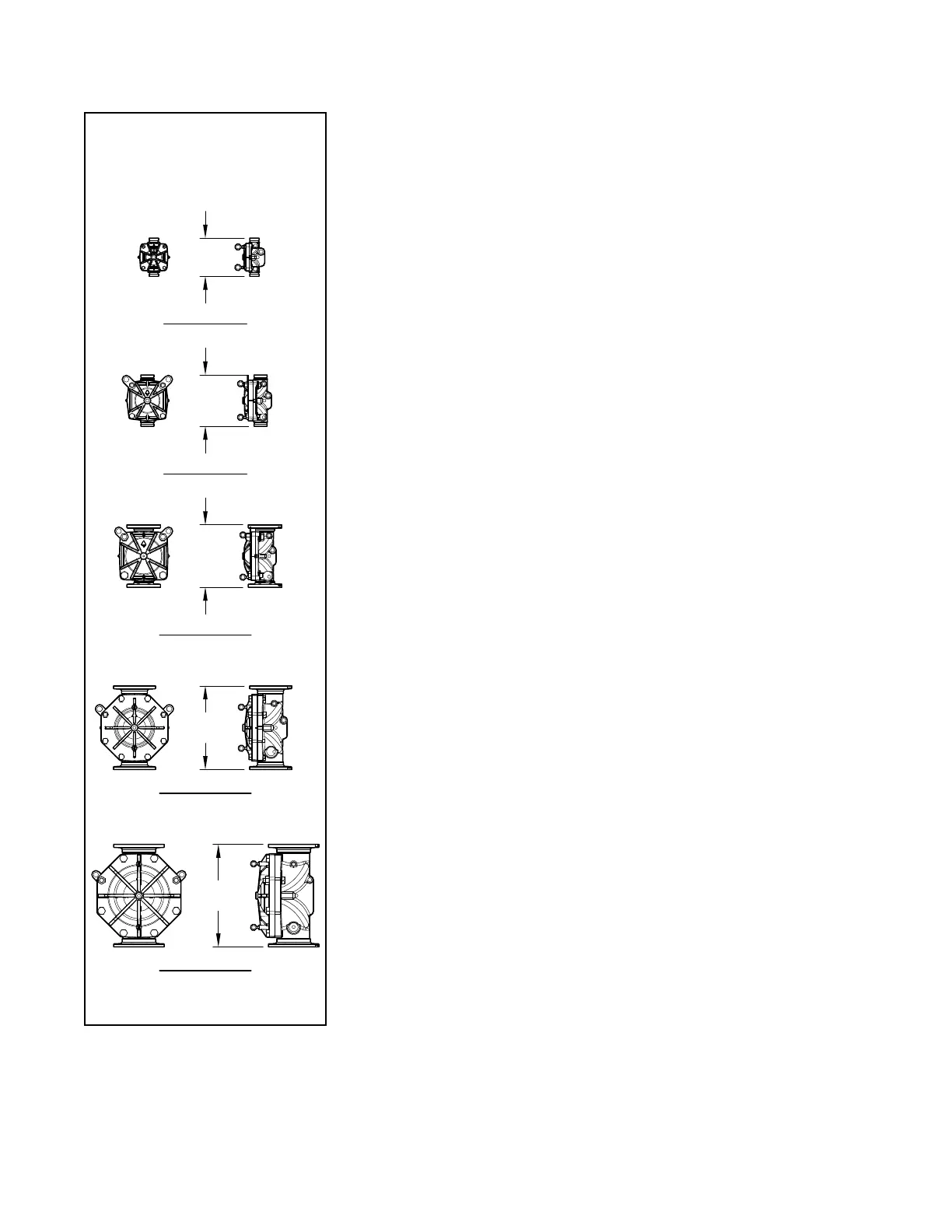

8 Inch (DN200)

6 Inch (DN150)

4 Inch (DN100)

3 Inch (DN80)

2 Inch (DN50)

22-3/8"

(569 mm)

16-3/4"

(425 mm)

13-3/4"

(349 mm)

10-3/16"

(260 mm)

27-7/16"

(697 mm)

ARE APPLICABLE TO

ALL END CONNECTION

CONFIGURATIONS

AVAILABLE PER

VALVE SIZE

FIGURE 6

PRV-1

A VALVE

TAKE-OUT DIMENSIONS

Loading...

Loading...