22 ©2010 Johnson Level & Tool - Rev. 1

6. Turn the laser 90° and place it on the platform. Position the

laser so the Y-direction is facing the wall. Perform Y-direction

self-check with the same method as X-direction self-check,

and mark point C and point D by turns.

7. If point C and point D are within 1/16” at 25’, the accuracy is

within tolerance.

Accuracy Calibration

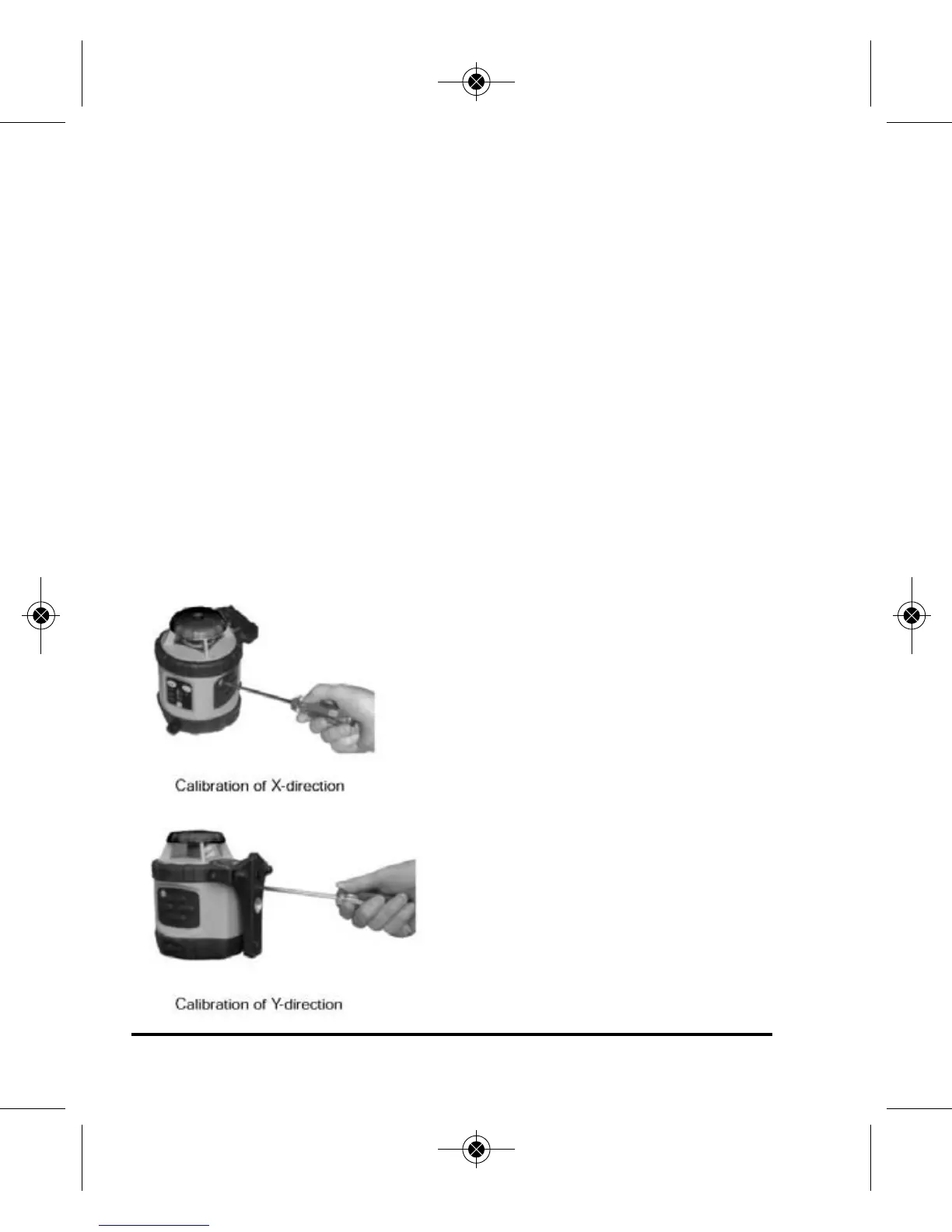

1. As shown in the following figures, screw off the adjustment-hole

bolt with the cross screwdriver, and adjust the fine-adjustment

bolt in the instrument core with a flat head screwdriver until the

laser line in within 1/8” at 50’.

2. Adjust the X-direction and the Y-direction with the same method.

Note: The laser should be turned off and the compensator

must be locked prior to making any

adjustments. If the accuracy is

beyond tolerance, calibrate the

X-direction through the adjustment

hole as shown.

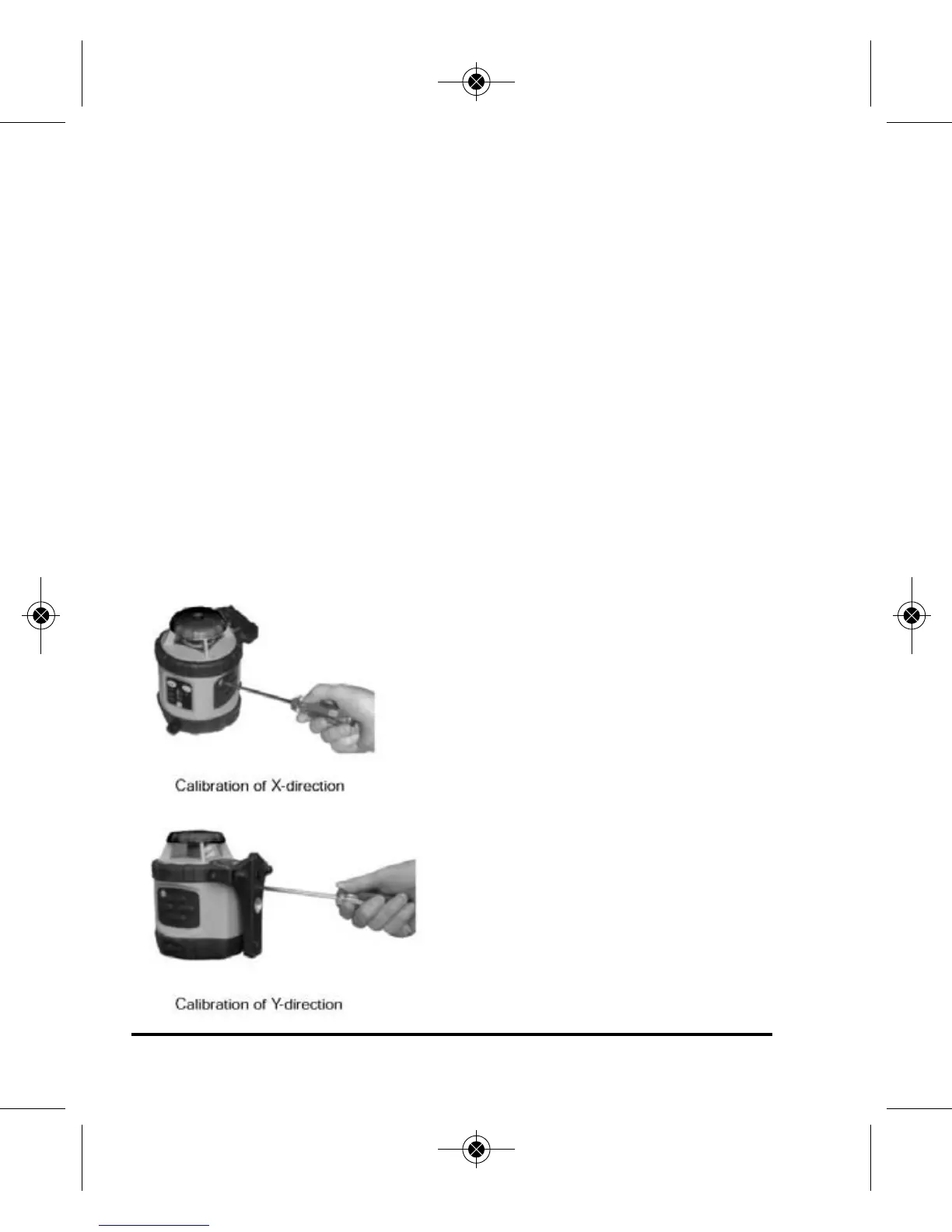

3. After X is calibrated, rotate the

instrument 90º to calibrate the Y-

direction.

Note: The alkaline batteries

must be removed to access the

instrument core with a flat head

screwdriver.

4. Reinstall the adjustment-hole bolt.

3515H_Manuals 6/2/10 9:00 AM Page 22

Loading...

Loading...