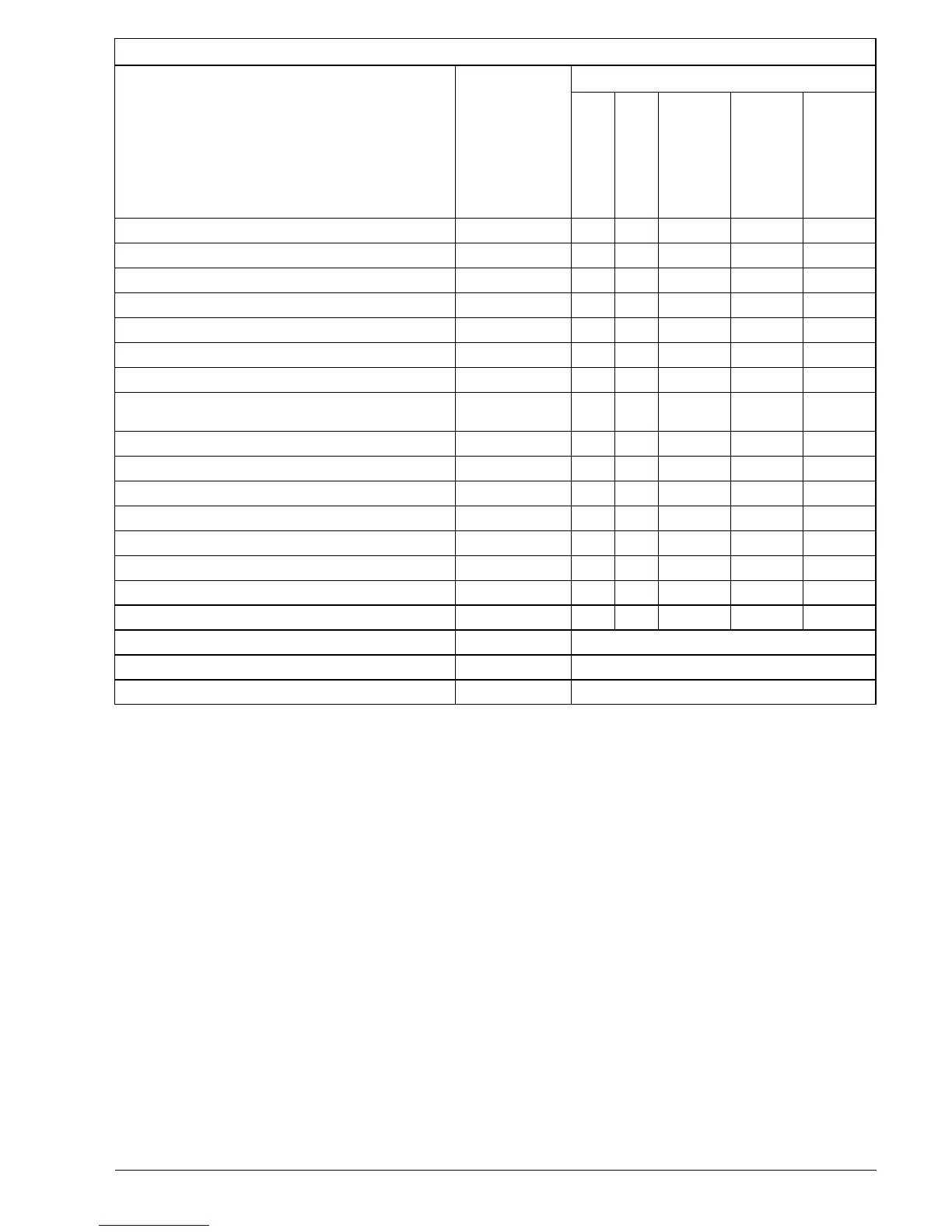

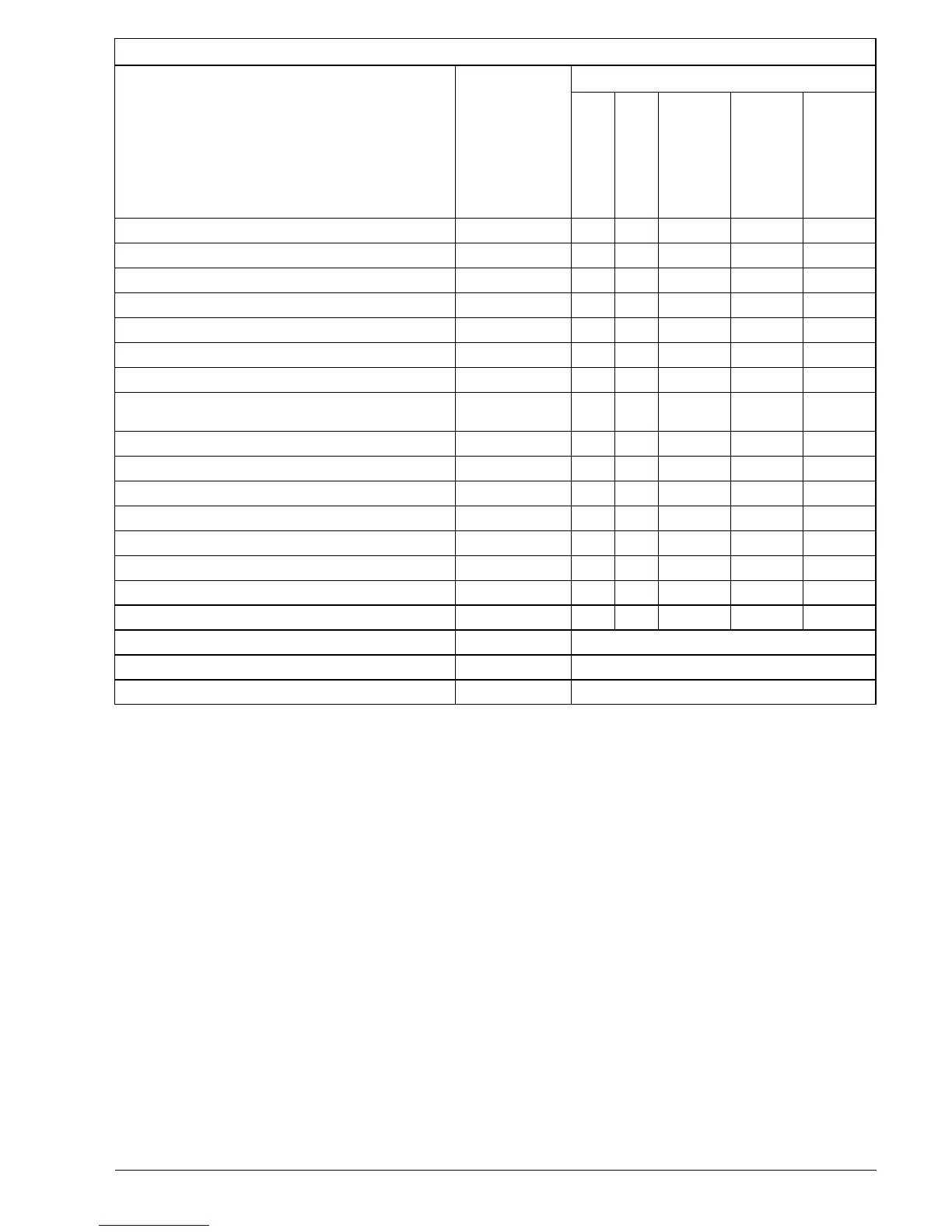

Maintenance - 51

Access

EMM

information, resolve service codes D D

Powerhead synchronization and linkage, inspect

(2)

7D D

Breather line, inspect D D

Crankcase oil, replace

(3)

11 D D

Crankcase oil filter, replace D D

Valve tappet clearance, inspect

(2)

DD

Starter pinion shaft, inspect and lubricate

(4)

9D

Gearcase lubricant, inspect fill level and condition of

lube

5D

Propeller shaft splines, inspect and lubricate 7 D

Spark plugs, replace

(2)

D

Fuel line filter, replace D

Decarbonize 10 D

Driveshaft splines, inspect and lubricate 8 D

Water pump, inspect and replace D

Fuel mixture, check D

Ignition timing, check D

Timing belt, inspect D Every 800 hours or four years

Low pressure fuel filter, replace D Every 400 hours or biannually

High pressure fuel filter, replace D Every 1000 hours

(1) Also recommended at 10-Hour Inspection

(2) Emission-related component

(3) Replace every 100 hours or annually if

Evinrude/Johnson Ultra

4-Stroke synthetic blend oil is not used

(4) Do not use light duty penetrating lubricants

D

Dealer Performed Service

O

Operator Performed Service

4

Evinrude/Johnson

anti-corrosion spray or

Evinrude/Johnson

“6 in 1” multi-purpose lubricant

5

Ultra-HPF

gearcase lubricant

6 Power Trim/Tilt Fluid

7

Triple Guard

grease

8

Evinrude/Johnson Molylube

P/N 175356

9 Starter Bendix Lube Only P/N 337016

10

Evinrude/Johnson

engine tuner

11

Evinrude/Johnson Ultra

4-Stroke

synthetic blend oil

Engine Maintenance and Inspection Schedule

Description

Engine Care

Product

Frequency

Each Use

10-Hour

Inspection

Every 50 Hours

or 6 months

Every 100 Hours

or Annually

Every 200 Hours

or Biannually

Loading...

Loading...