2-8

2

Fig.9 X-band

2) Installation procedures

a) Maintain a flat level surface on which to install the antenna.

• Use sufficiently thick steel material and reinforcement material for the antenna's

installation surface (mount base) to reduce vibration and impact. Keep the mount base

flat and smooth.

• If there is a partial gap between the mount base and the antenna chassis's legs, work on

the installation surface so that it becomes flat and smooth. If a gap exists and the

antenna is tightly clamped, the chassis will distort and become damaged by vibration.

b) Avoid using vibration-proof rubber and resin

• Do not insert an elastic body, such as vibration-proof rubber or resin, between the mount

base and the antenna chassis' legs. If rubber or resin is inserted, the amplitude of

vibration increases, resulting in the possibility of damage to the antenna. Furthermore,

if installation bolts become loose due to deterioration of rubber or resin, the antenna

may be damaged or fall from its mount.

3) Installation and clamping method

a) Installation direction

• Installation should be done so that the cable gland is oriented toward the stern.

b) Bolts, nuts and tightening torque to be used

• Use stainless steel bolts for the antenna and uniformly tighten all of the bolts using

double nuts for each bolt so that the antenna will not become loose (Table 2).

• Although the length of the bolt will differ according to the thickness of the mount base,

use a bolt long enough so that more than 4 millimeters of thread protrudes beyond the

double nuts after the double nuts have been tightened.

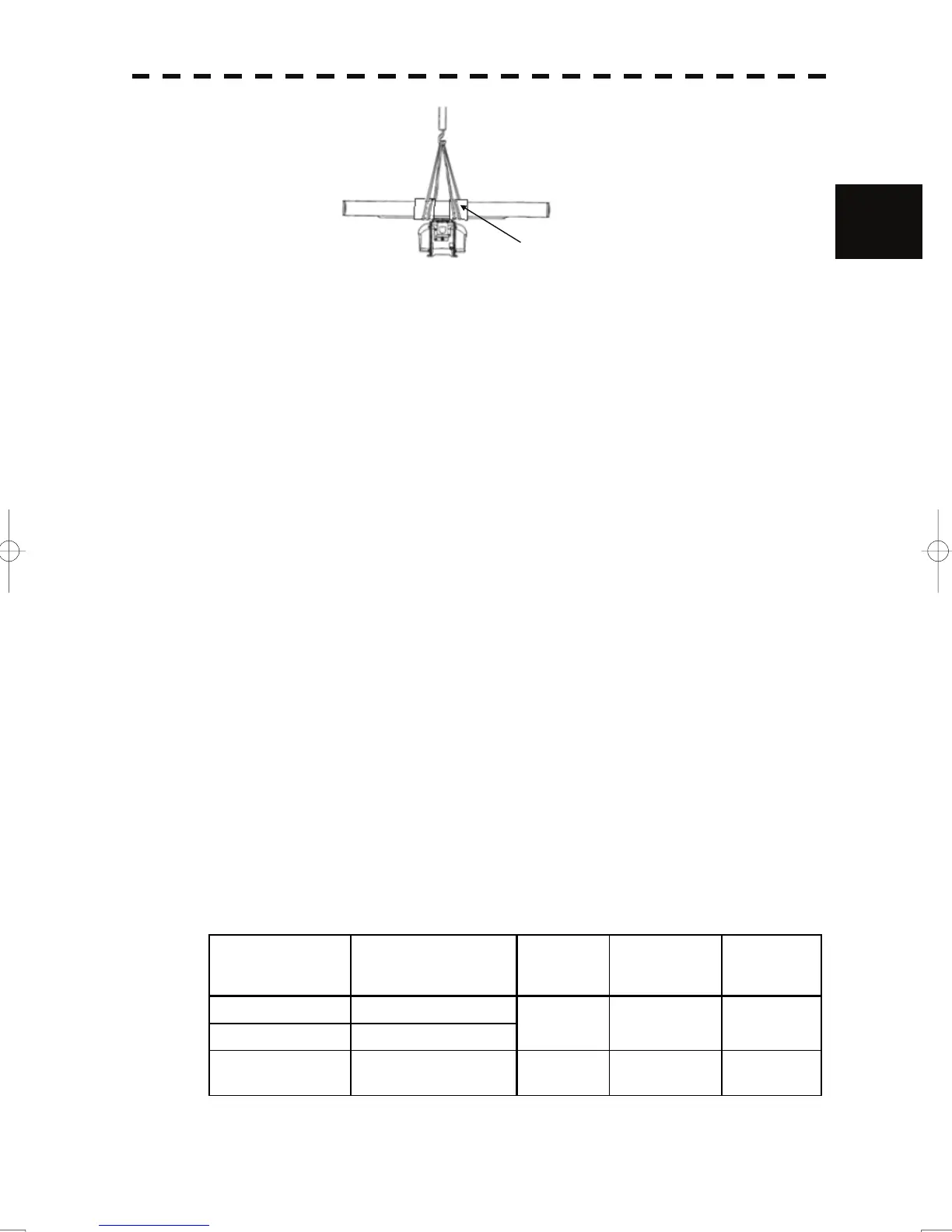

Table 2 Length of antenna mounting bolts and tightening torque

RADAR model Scanner Unit

Thickness of

Mount Base

(mm)

Bolt Torque (N-m)

JMA-5312-6/6HS NKE-2103-6/6HS

12

M10×55(mm)

SUS304

40

JMA-5322-7/9/6HS NKE-2254-7/9/6HS

JMA-5332-12 NKE-1130 19

M12×65(mm)

SUS304

65

Wrap a cloth

Loading...

Loading...