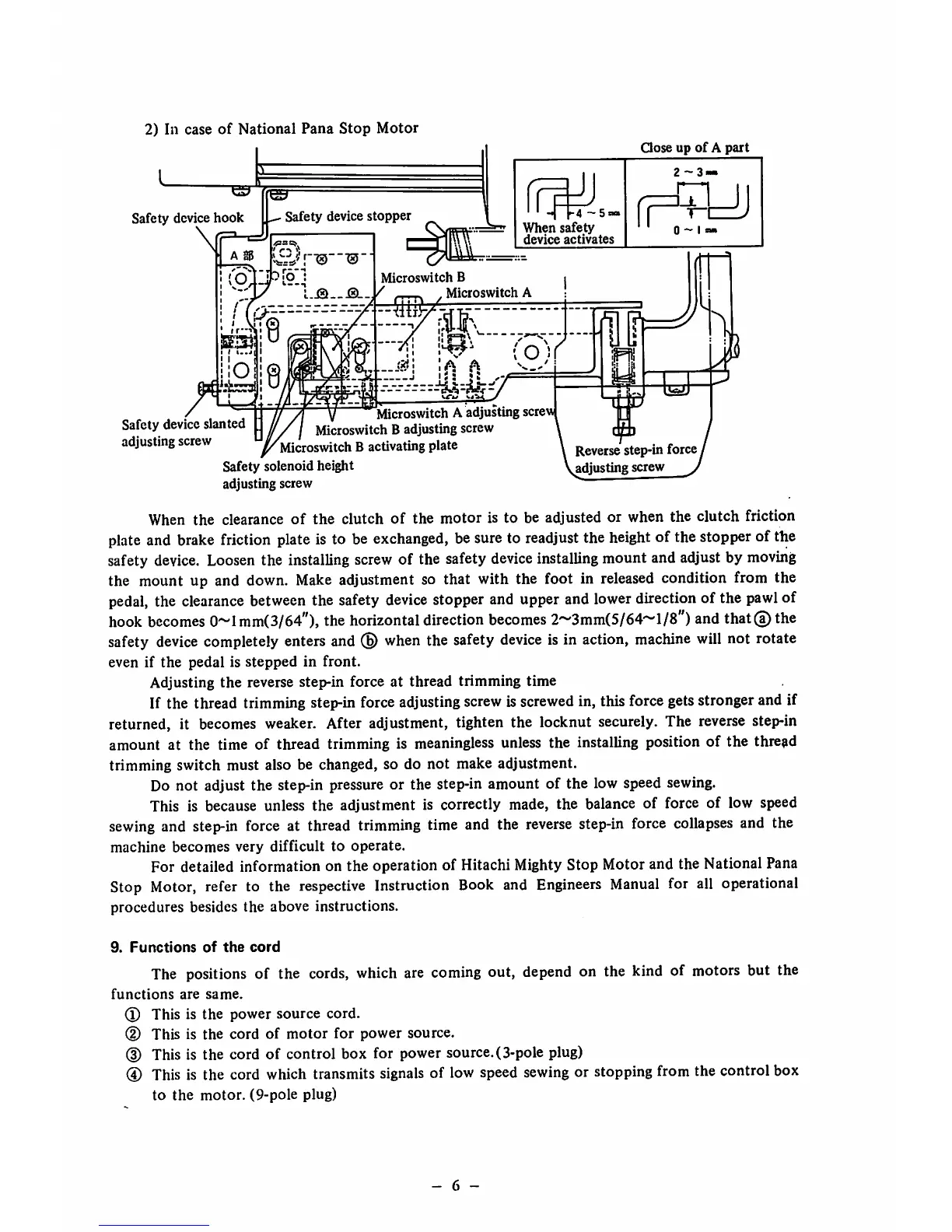

2) In case

of

National

Pana

Stop

Motor

Safety device

hook

\

Safety device slanted

adjusting

screw

Safety

device

stopper

Microswitch

B

Microswitch

A

Qose

up

of

A

part

When

Si

device

s

>-4 — 5 not

ifety

ictivates

2-3.

0 - 1 «

m

Microswitch A adjusting screw

Microswitch B adjusting screw

Microswitch B activating plate

Safety solenoid height

adjusting screw

Reverse step-in force

adjusting screw

When the clearance

of

the clutch of the motor is to be adjusted or when the clutch friction

plate and brake friction plate is to be

exchanged,

besureto readjust the

height

of the stopperof the

safety

device.

Loosen

the installing

screw

of the safety

device

installing mount and adjust by

moving

the mount up and

down.

Make

adjustment so that with the foot in

released

condition from the

pedal,

the

clearance

between

the safety

device

stopper and upper and

lower

direction of the

pawl

of

hook

becomes

0~lmm(3/64"), the

horizontal

direction

becomes

2~3mm(5/64~l/8")

and

that@ the

safety

device

completely enters and

(B)

when

the safety

device

is in action,

machine

will

not rotate

even if the pedal is

stepped

in front.

Adjusting

the

reverse step-in force at thread trimming time

If the thread trimming step-inforce adjustingscrewisscrewedin, this force gets stronger and if

returned, it

becomes

weaker.

After adjustment, tighten the locknut securely. The

reverse

step-in

amount at the time of thread trimming is meaningless unless the installing position of the thread

trimming switch must also be changed, so do

not

make adjustment.

Do not adjust the step-in pressure or the step-in amount of the low speed sewing.

This is because unless the adjustment is correctly made, the balance of force of low speed

sewing

and

step-in

force

at thread trimming time and the

reverse

step-in force

collapses

and the

machine

becomes

very

difficult

to

operate.

For detailed information on the operation of Hitachi MightyStop Motor and the National Pana

Stop

Motor,

refer to the

respective

Instruction

Book

and

Engineers

Manual

for all operational

procedures besides the above instructions.

9.

Functions

of

the

cord

The positions of the

cords,

which are

coming

out, depend on the kind of motors but the

functions

are

same.

(l)

This

is

the

power

source

cord.

(D This is the

cord

of

motor

for

power

source.

(D This is the cord of control box for power source.(3-pole plug)

@ This is the cord which transmits

signals

of low speed

sewing

or stopping from the control box

to the motor. (9-pole plug)

- 6 -

Loading...

Loading...