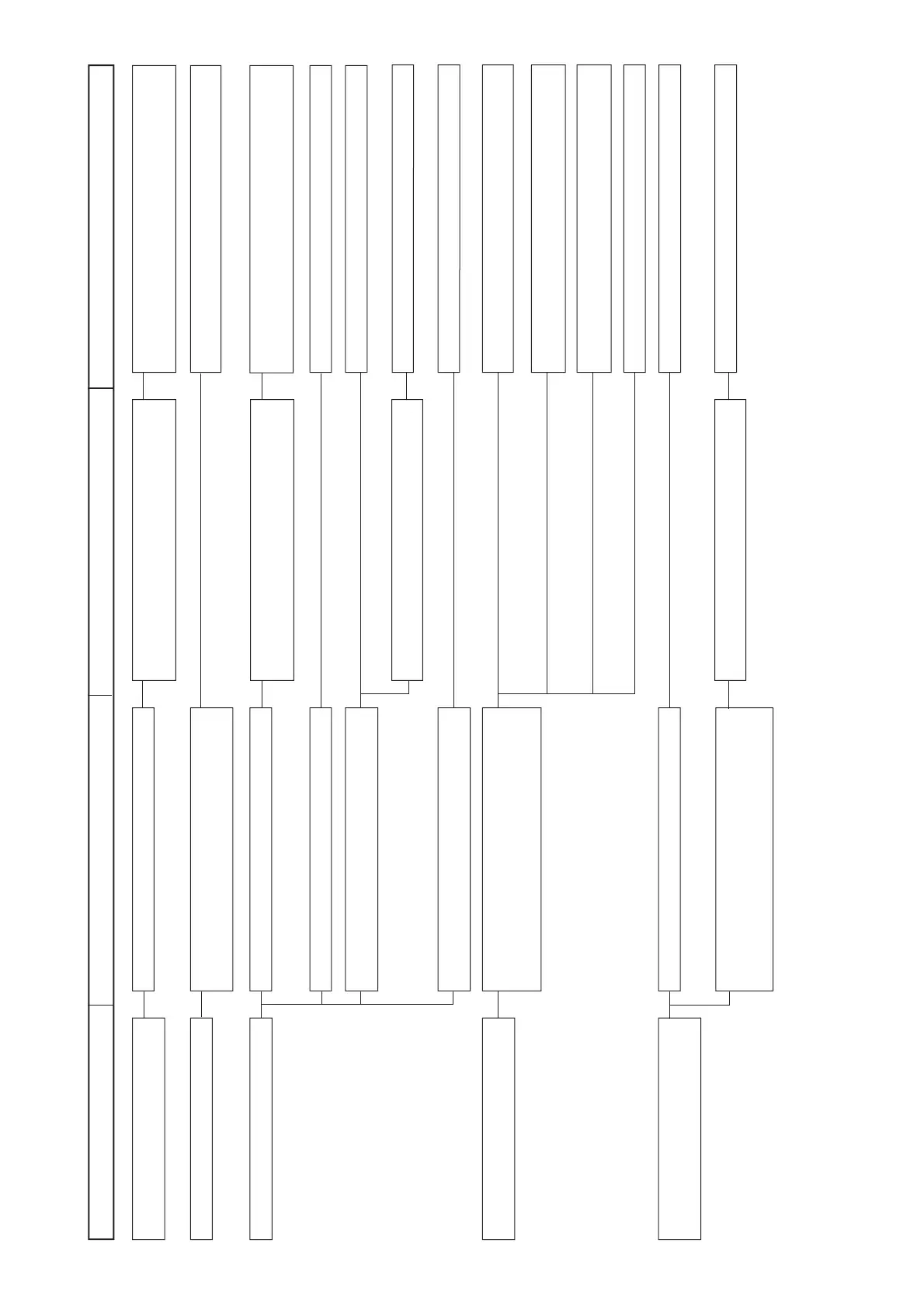

− 136 −

7. Needle thread is not trimmed at the time of

idle stitching.

8. Wiper fails to sweep thread.

(Bird's nest prevention type)

9. Defective needle thread clamp

10.Air pressure is decreased, suction force

is decreased and thread is not sucked.

11.Air pressure is decreased and thread is

not sucked since dust bag clogs with too

much thread waste.

Stroke of the thread take-up spring is too large.

When sewing product is thin and needle thread tension is

low, thread draw-out amount is excessive and wiper fails

to sweep the thread.

Remaining length of needle thread is too short.

Position of the wiper is improper.

Air pressure is decreased, suction force is decreased and

thread is not sucked.

Air pressure is decreased and thread is not sucked since

dust bag clogs with too much thread waste.

When remaining amount (thread take-up lever) of needle

thread after completion of needle thread clamp is small,

bobbin thread is brought to the position above the cloth at

the first stitch of the start of sewing.

Knife built in the cloth presser has become dull.

Needle thread holding is weak and thread on the needle

thread holding side is drawn out at the time of needle thread

trimming. As a result, remaining length of needle thread is

lengthened.

Rough motion of needle thread occurs at the time of

thread trimming and knife misses needle thread and does

not trim it.

Thread is swept with the wiper and brought to the suction

port. However, needle thread is too short and comes off

the wiper on the way or fails to be sucked.

Air consumption in the factory is increased and the

pressure is decreased.

Clamping force is decreased due to the decrease of air

pressure.

Decrease the stroke of thread take-up spring.

(When decreasing the stroke, be careful of the isolated idling

loops.

Adjust the needle thread draw-out unit so that the needle thread

draw-out amount is reduced.

Adjust the length of remaining thread so that the length of needle

thread after thread trimming is adjusted to approximately 15

mm of suction amount.

Place the wiper at the proper position.

Adjust to the standard pressure, 0.6MPa.

Install more air compressors.

Remove thread waste or the like in the dust bag.

Adjust the needle thread draw-out unit to increase the needle

thread draw-out amount.

Perform thread tension release at the start of sewing. (Function

setting No. 100)

Make needle thread draw-out motion again after needle thread

clamping. (Function setting No.18 : 2.)

Make function both function setting No. 100 and No. 18 : 2.

Replace the needle thread trimming knife.

Adjust air pressure to 0.6MPa.

Trouble Cause 1 Cause 2 Corrective measure and

Loading...

Loading...