− 124 −

•Re-enter data after reset operation.

•Set pattern No. and number of stitches.

• Re-enter data after reset operation.

• Correct data of pattern which becomes error.

• Reset operation

• In case of deletion, release the use of pattern

sewing, continuous stitching or cycle stitching

used, and perform again deletion.

• Re-enter data after reset operation.

• Set zigzag width of condensation custom pattern

within max. zigzag width limitation.

• Re-enter data after reset operation.

• Set the position of stitch base line within max.

zigzag width limitation.

• When condensation custom is selected, check

and correct the position of condensation.

• Re-enter data after reset operation.

• Set the position of stitch base line within max.

zigzag width limitation.

• Turn OFF the power.

• Connect the proper panel.

• Turn OFF the power.

• Consist system versions with each other.

•Check the motor signal connector (CN38) for

loose connection and disconnection.

•

Check whether the motor signal cord has broken since

the cord is caught in the machine head or the like.broken

since the cord is caught in the machine head or the like.

•Turn OFF the power.

• Turn OFF the power.

• Disconnection of relay cable of reverse feed

control lever sensor.

• Trouble of reverse feed control lever sensor.

•Check whether the solenoid is short-circuited.

•

Check whether the applied power voltage is higher

than the rated voltage + (plus) 10% or more.

•Check whether 100V/200V changeover

connector is set by mistake.

In the above cases, POWER circuit board has broken.

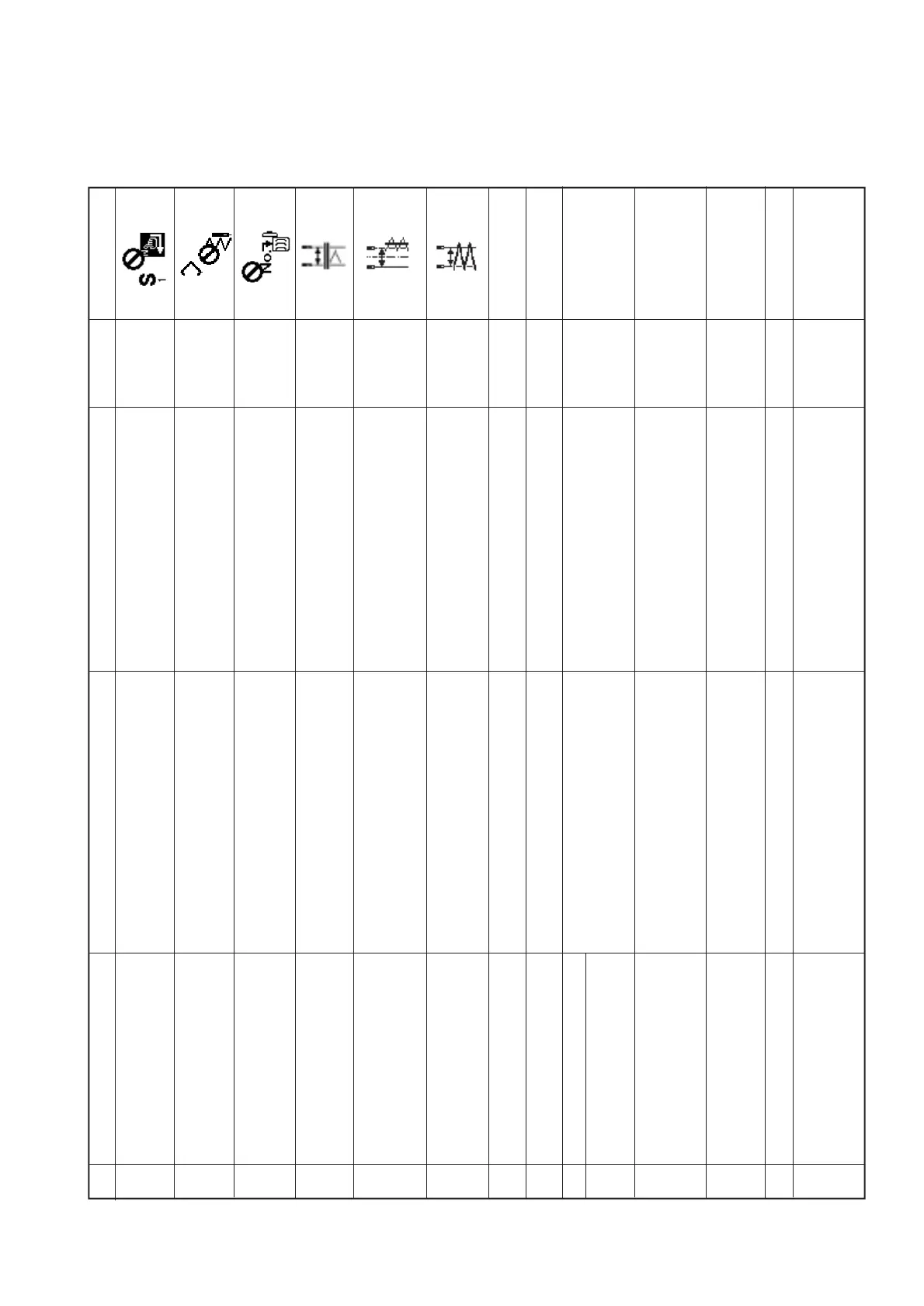

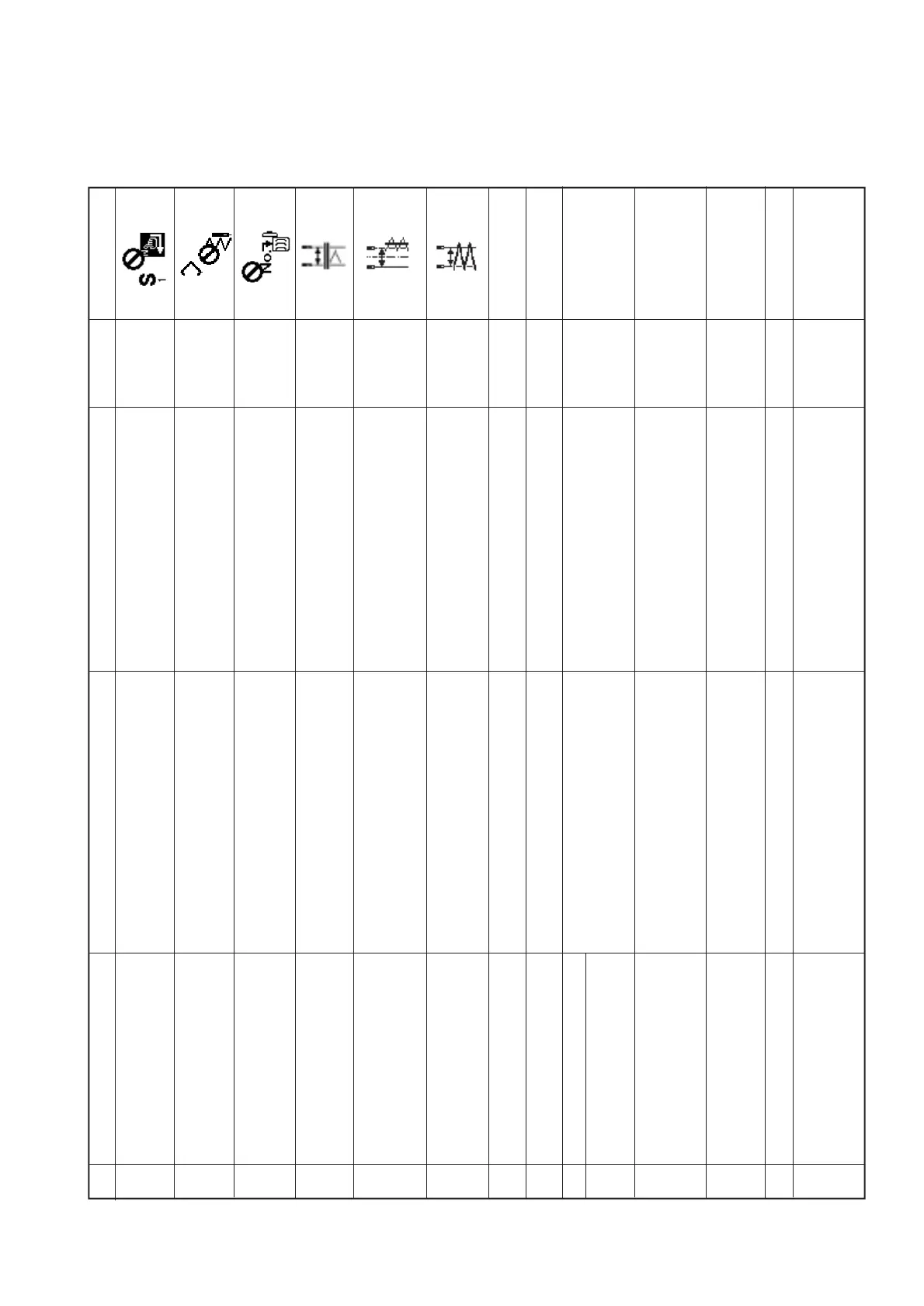

490

491

492

493

498

499

703

704

730

731

733

734

810

811

Pattern setting error of continuous

stitching and cycle stitching

Cycle stitching pattern error

Data deletion impossible

Condensation custom pattern width

error

Position of stitch base line error

Max. zigzag width error

Connection of panel which is not sup-

posed

Inconsistency of system versions

Encoder failure

Motor hole sensor failure

Reverse rotation of main shaft motor

Reverse feed control lever sensor

erroe

Solenoid short-circuit

Overvoltage

•

When pattern No. is not set to continuous stitching.

•

When the number of stitches of 1st step of continuous stitching is

"0".

• When pattern No. is not set to cycle stitching.

• When pattern to be used in cycle stitching becomes

error.

• When data to be deleted is used in pattern sewing,

continuous stitching or cycle stitching.

• When zigzag width of condensation custom pattern

is larger than max. zigzag width limitation.

• When the set zigzag width is within max. zigzag

width limitation, but zigzag position exceeds max.

zigzag width limitation according to the position of

stitch base line.

• When specified zigzag width is within max. zigzag

width limitation, but zigzag position exceeds max.

zigzag width limitation according to the position of

stitch base line.

• When panel connected to the sewing machine is

the kind which is not supposed.

• When system versions are inconsistent.

• When the motor signal is not properly inputted.

• State that the sewing machine is rotating in the

different direction from the normal rotating direc-

tion at 500 rpm or more continues 40 times or more

while motor is running (excluding holding of needle

position).

•

Abnormality of reverse feed control lever sensor

detection.

•

When the short-circuited solenoid is desired to be driven.

• When voltage upper than guaranteed one is

inputted.

• When 200V is inputted for 100V setting.

7 times flash

7 times flash

−

7 times flash

7 times flash

7 times flash

−

−

−

−

−

−

−

No.

Description of error detected

Cause

Item to be checked or corrective measure

Mirror LED flash

Pictograph display

Loading...

Loading...