− 143 −

19. T stitch pattern is dirty.

20. Material falls (is caught in).

21. Step-out of motor occurs.

19-1) “0” position is slipped.

19-2) Stitch tightness is not good.

20-1) Clearance between throat plate and

feed dog is too large.

21-1) Assembling torque of feed mechanism

is too heavy.

1-A) State of feed dog is different from the

standard state.

Make it the standard state.

Perform compensation and input of feed amount “0”.

(Feed amount may be different from the input value due to the slide characteristic of material

or the like.) ... Refer to the Instruction Manual.

Adjust the feed amount. (Return the mechanical adjustment value to the standard.)

Refer to 3-(1)-2) Adjusting the feed amount.

Replace the thread tension with 2-disk type thread tension of lockstitch type.

Part No. : 40017095

Replace the feed dog with that adjusted to the feed pitch used. (Make minimum the clearance

between throat plate and feed dog.) ... Standard delivery gauge is for 5 mm feed.

Re-adjust the feed mechanism torque at the time of assembling the feed stepping motor unit.

Refer to 3-(3)-2) Adjusting the feed amount.

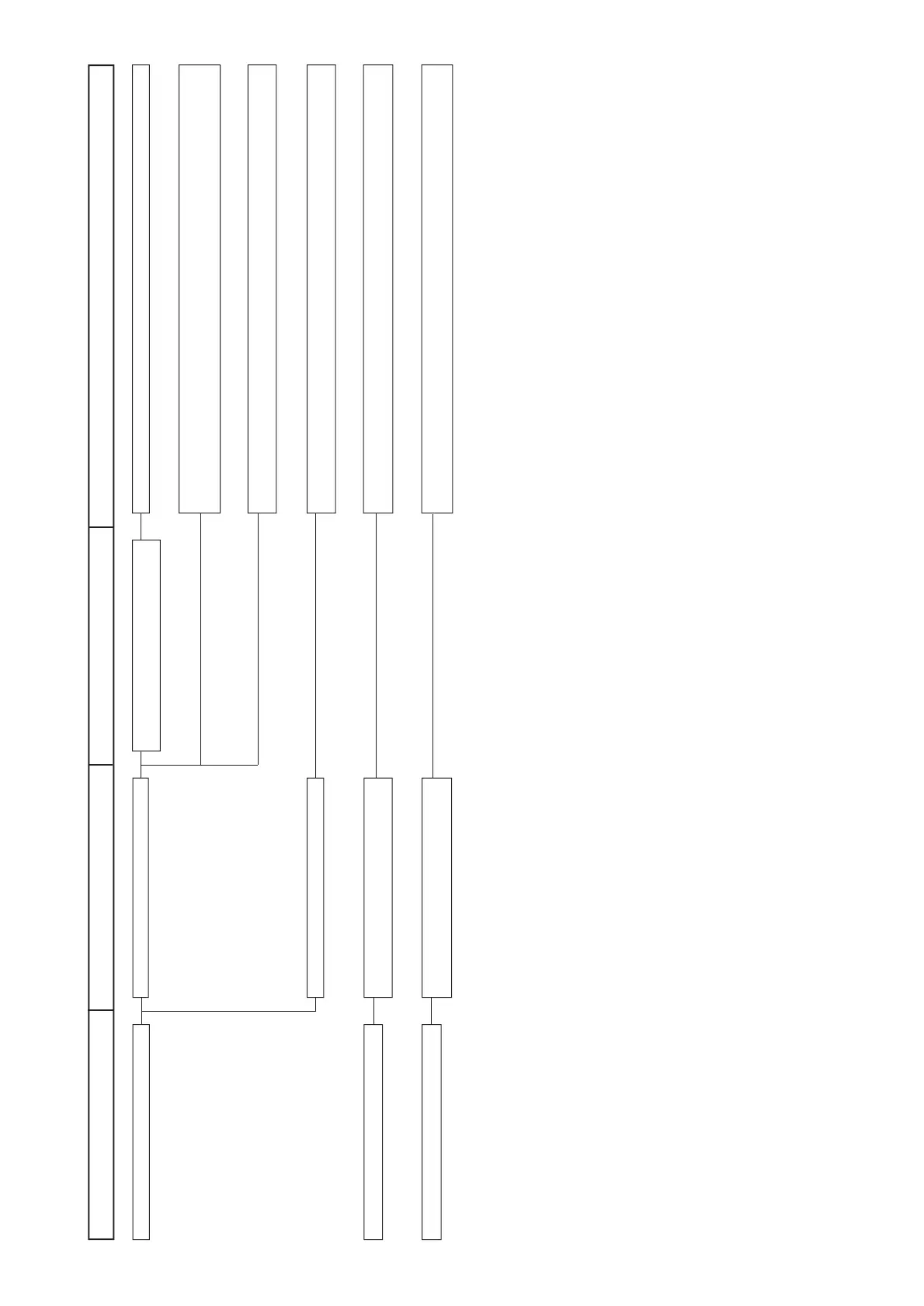

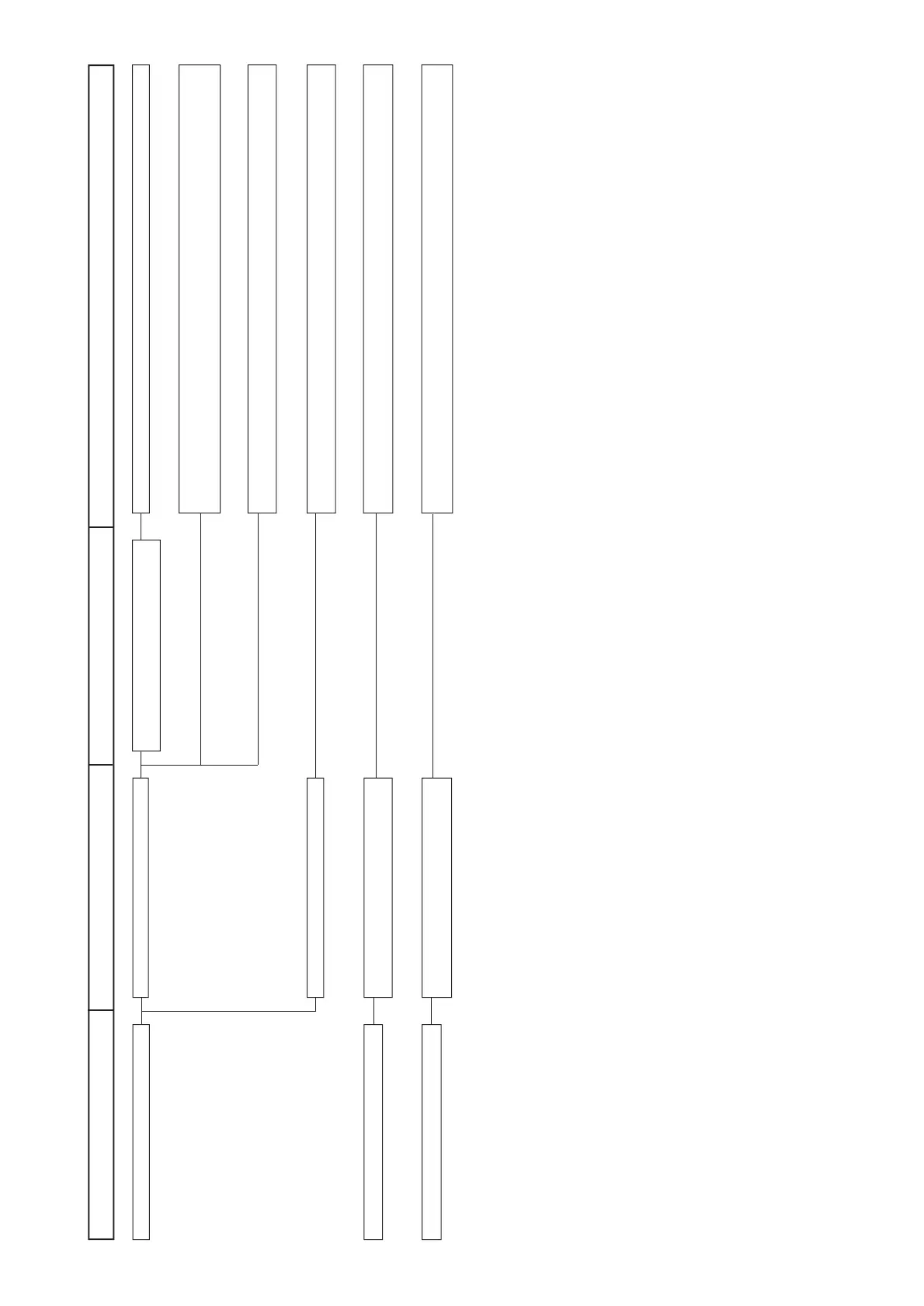

Trouble Ca1use 1 Cause 2 Corrective measure and adjusting procedure

Loading...

Loading...