− 69 −

Caution in disassembling Caution in assembling

4) Loosen setscrews 4 in the needle bar support base shaft bracket

collar. By loosening setscrews 4 in the needle bar support base

shaft bracket collar, connecting shaft 5 slides to the right or left.

5) Perform centering while sliding the needle bar support base shaft to

the right or left, and set the shaft while temporarily tightening setscrews

4 in the needle bar support base shaft bracket.

<Connecting shaft : disassembling and replacement>

1. In order to improve the needle rocking quality, connecting shaft 5 is

classified as the selective part.

Select connecting shaft 5 which smoothly moves without any play.

2. For coupling connecting shaft 5, insert needle rocking link !1 between

connecting shaft 5 and connecting shaft collar 6, and tighten

setscrew !5 in the connecting shaft collar so that there is no play.

13) Adjusting needle rocking "0" position

1. Set the mode to the hook adjusting mode (refer to (12) Adjusting the

needle-to-hook timing and the needle guard) of 3. STANDARD

ADJUSTMENT.), determine needle entry "0", and tighten setscrew

8 in the needle bar support base bracket.

14) Checking the lateral torque of the needle bar support base

Check that the torque of pulling and pushing is less than 10N within

the range of 10 mm of the needle bar rocking.

Measure at A and B sections using the spring balancer as shown in

the figure.

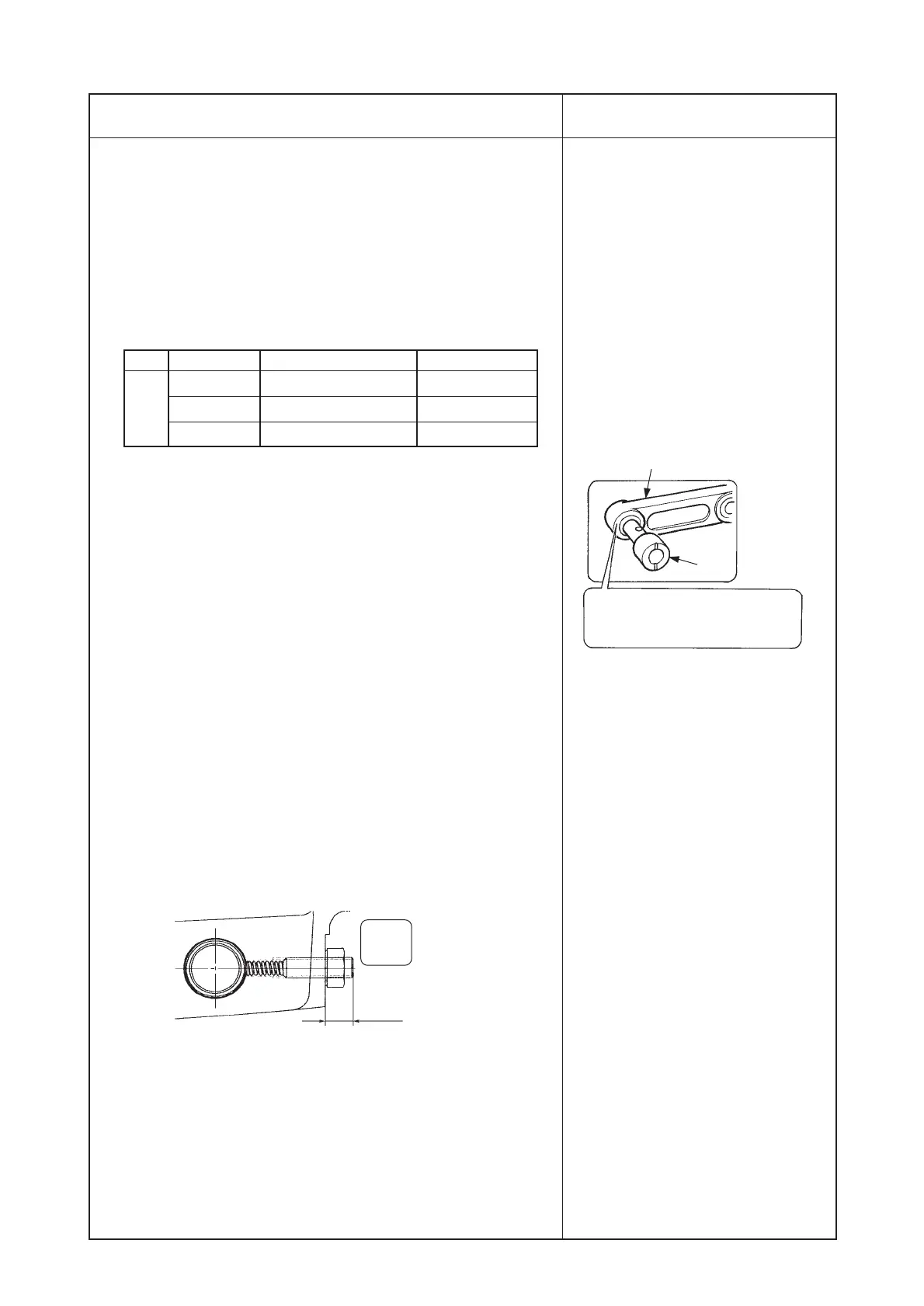

15) Tightening the slide resistance screw

1. Adjust the height of the slide resistance screw so that it becomes the

height of the spring measured in advance (factory-adjusted value) at

5) Releasing the slide resistance screw or the aimed value of pulling

and pushing is 14N to 15N (11N to 18N in the whole region) within

the range of 10 mm of the needle bar rocking at A and B sections

using the spring balancer as shown in the figure.

In addition, the height of the screw can be adjusted to 5.5 ± 1 mm

16) Assembling the outer components

1. Assemble the outer cover removed.

17) Adjusting the hook and the height of the needle bar

1. Perform adjusting of the height of the needle bar, and needle-to-blade

point of the hook in the hook adjusting mode (refer to (12) Adjusting

the needle-to-hook timing and the needle guard of 3. STANDARD

ADJUSTMENT) using timing gauge E.

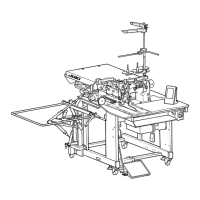

™ When centering is not obtained,

needle bar support base bracket 7

moves, and the lateral needle

rocking torque becomes heavy

when tightening screw 8 in the

needle bar support base bracket in

the next process, resulting in step-

out.

™ When tightening setscrews 4 in the

needle bar support base shaft

bracket collar, be careful so as not

to damage sensor slit 9 or origin

sensor !0.

™ When the torque becomes more

than 10N within the range of 10 mm

of needle bar rocking, perform re-

adjustment from step 12).

™ When the machine is operated with

the abnormal torque, worn-out or

step-out will be caused.

™ When the adjustment is performed

with the value other than the

specified value, problems such as

step-out, deterioration of sewing

performance, worn-out, etc. can be

considered. Be sure to use the

machine with the specified value.

No. Part No. Name of part Shaft diameter

40008119 Connecting shaft A Large

40008120 Connecting shaft B Medium

40008118 Connecting shaft C Small

Dimension of height of

screw

5.5 ±

1 mm

Apply exclusive grease to the

grooves of the holes in connecting

shaft 5 and needle rocking link !1.

5

!1

5

Loading...

Loading...