AMS-215D, 221D, 215D P TYPE, 221D P TYPE (September, 2003) 3/3

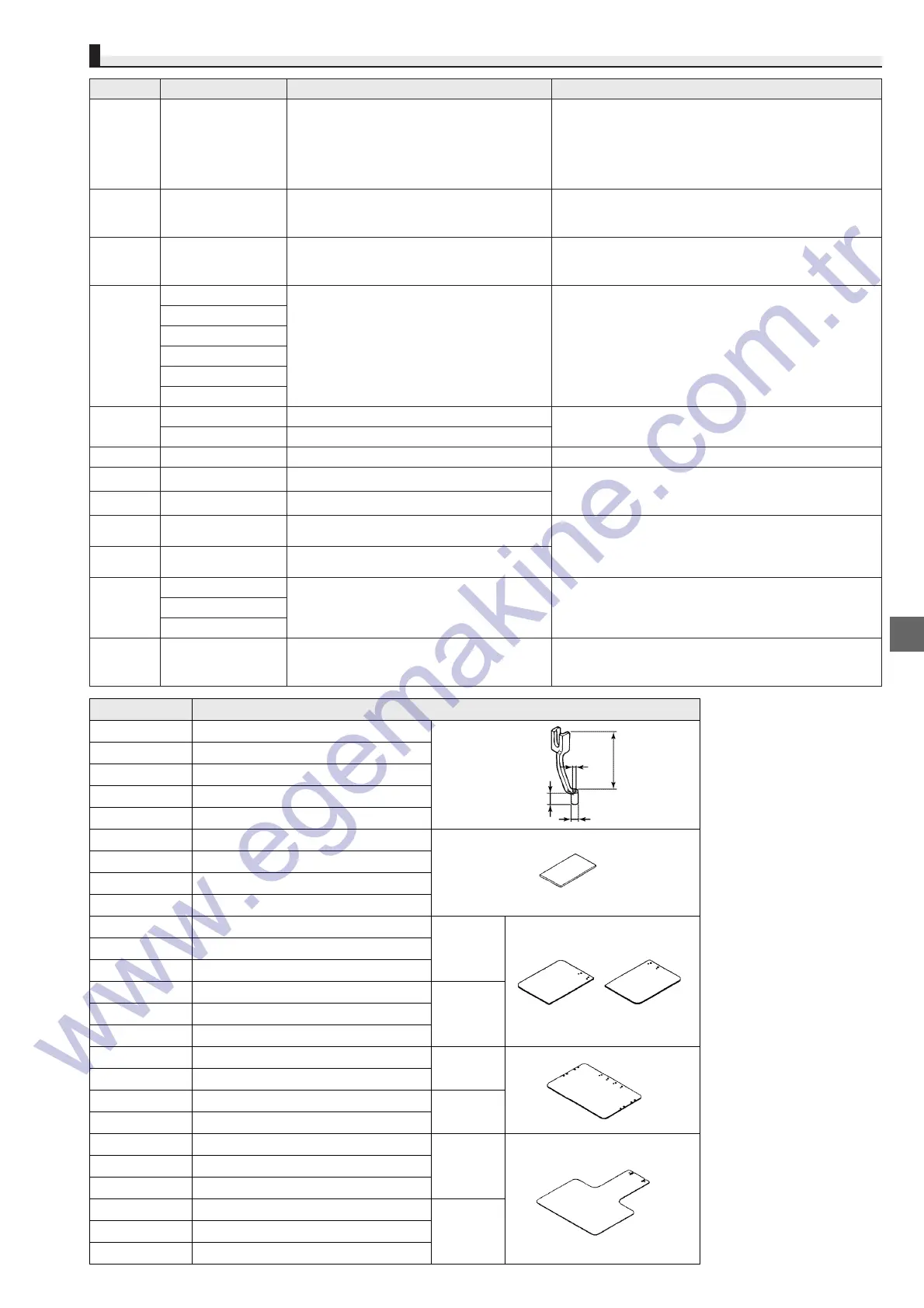

φA

φB

R

L

φA×φB×R×L

OPTIONS

―

―

―

B5019-222-0B0

PV-150209000

142-04754

PX-500014000

SS-6152212SP

WP-0612516SD×2

B2120-215-0A0

B4150-210-DA0

B4720-221-DB0

―

―

B2581-221-DA0

B2582-221-0A0

B2640-215-0B0

B2641-215-0A0×2

SS-6150610SP×4

M8607-580-AA0

Programming software for computer-controlled

sewing machines

Programming software for computer-controlled

sewing machines

Pneumatic inverted clamp device

Thread tension controller No.3

Needle thread clamp device

Junction cord

Needle cooler

Milling unit (for AMS-215D)

Milling unit (for AMS-221D)

Cassette holder fixing base (asm.)

Cassette holder (asm.)

One-touch utility clamp

I/O expansion unit

This software is to input and edit sewing data of JUKI's latest

sewing machines. Its versatile input functions allow to

input sewing data of each electronic sewing machine model

easily, accurately, and quickly. It supports high quality

production with high added value by utilizing and creating

original data for specific designs and applications.

The PGM-20 is provided with many different input functions

to permit interactive data creation, free from difficulties,

using a general-purpose personal computer or digitizer.

The device is designed for installation on the machine

provided with a double-stepped stroke feeding frame

(specification: L).

The tension controller unit is used to partially change the

needle thread tension during the sewing of a pattern.

This device prevents the thread from tangling at the start of

sewing.

―

The milling unit can be installed on the machine to allow

the operator to easily machine a feeding frame or feed

plate.

The next material to be sewn can be placed between the

top and bottom plates of the cassette holder while the

machine is still engaged in the sewing of the currently set

material.

The feeding frame and the feed plate can be quickly

changed without any tools.

The machine is provided with external input/output ports

that are very convenient when re-modeling the machine

with accessory devices attached.

Model Part No. Description Feature

Part No. Description

B1601-210-D00A Intermediate presser A 2.2×3.6×6×29.5

B1601-210-D0BA Intermediate presser B 2.7×4.1×6×29.5

B1601-210-D0CA Intermediate presser C 2.7×5.5×6×29.5

B1601-210-D0E Intermediate presser E 1.6×2.6×6×29.5

B1601-210-D0FA Intermediate presser F 2.2×3.6×9×29.5

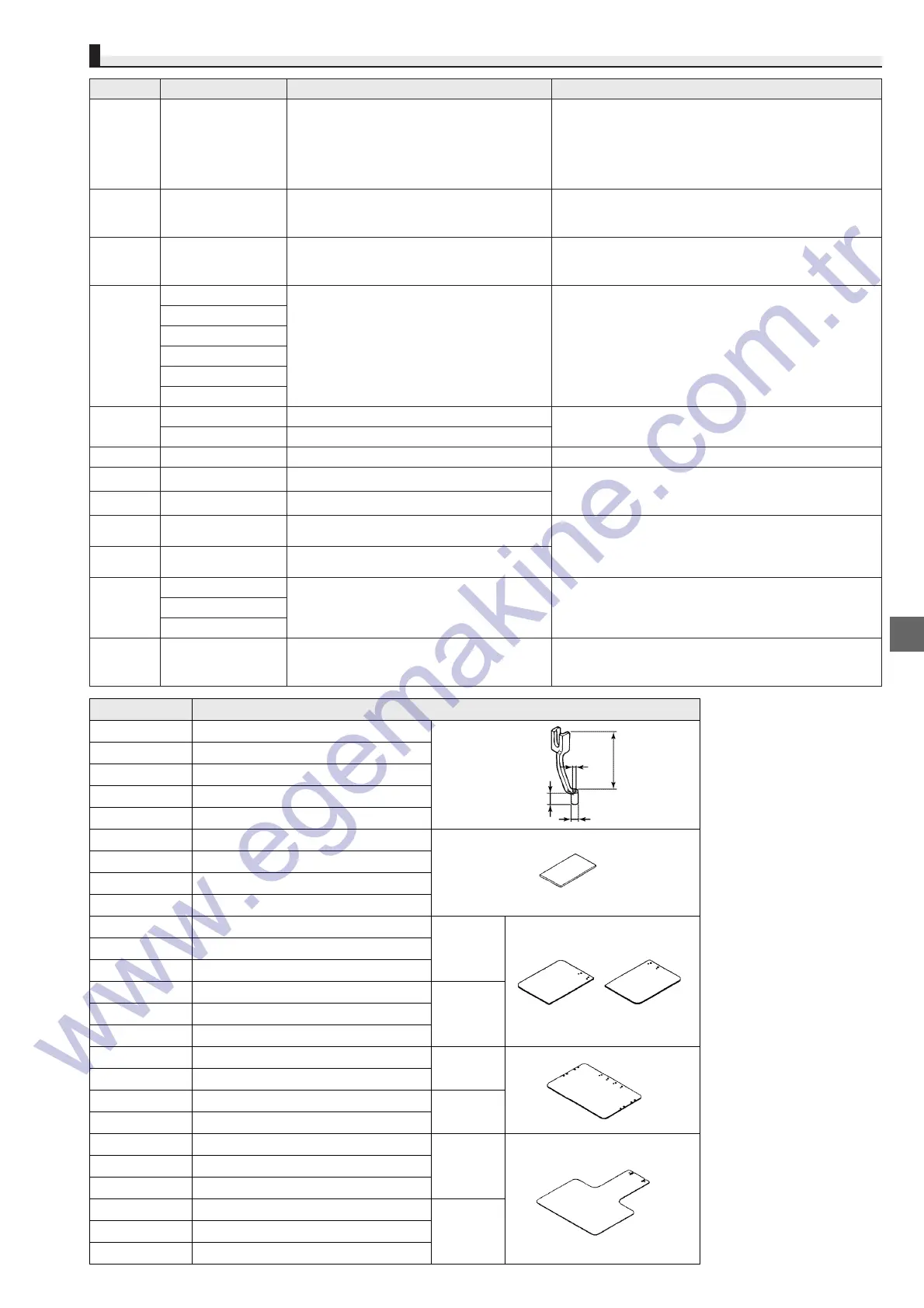

B2587-220-000 Work clamp paper material (A)

B2588-220-000 Work clamp paper material (B)

B2595-220-00A Presser cloth sheet

B2595-220-00B Presser cloth sheet B

B2622-215-D00 Feeding frame blank, right (with knurl)

B2623-215-D00 Feeding frame blank, left (with knurl) AMS-215D

B2626-215-D00 Feeding frame blank (with knurl)

B2622-221-000 Feeding frame blank, right (with knurl)

B2623-221-000 Feeding frame blank, left (with knurl) AMS-221D

B2626-221-000 2-step feeding frame blank

B2620-215-D00 Feeding frame blank plate (with knurl)

AMS-215D

B2620-215-D00 Feeding frame blank plate (without knurl)

B2620-221-000 Feeding frame blank plate (with knurl)

AMS-221D

B2621-221-000 Feeding frame blank plate

B2552-215-D0A Lower plate blank (without knurl)

B2552-215-D0B Lower plate blank (with knurl) AMS-215D

B2552-215-D0C Lower plate blank (0.5mm)

B2552-221-D0A Lower plate blank (without knurl)

B2552-221-D0B Lower plate blank (with knurl) AMS-221D

B2552-221-D0C Lower plate blank (0.5mm)

PM-1

PGM-20

FU03

―

―

―

MU13

MU14

―

―

―

Loading...

Loading...