Instruction Manual

Section Five

the steps in set-up procedure given in parts I, II, and III for primary

clearance. Match the secondary clearance angles on the cutter or use

the suggested clearance from table V, on page 107. The toothrest may

have to be adjusted, the workhead tilted one way or the other farther

(IN THE VERTICAL PLANE), or, when the machines have a tilting wheel-

head, the Wheelhead tilted farther than the primary angle setting. Suffi-

cient grinding is accomplished in order to reduce the primary land to about

1

/

16

or

1

/

32

inch in width

C. Grinding Procedure:

The process duplicates that given in parts I and II for the face and chamfer

clearance lands, except as noted in B-1 above.

CHAPTER 9

Form Relieved Cutters

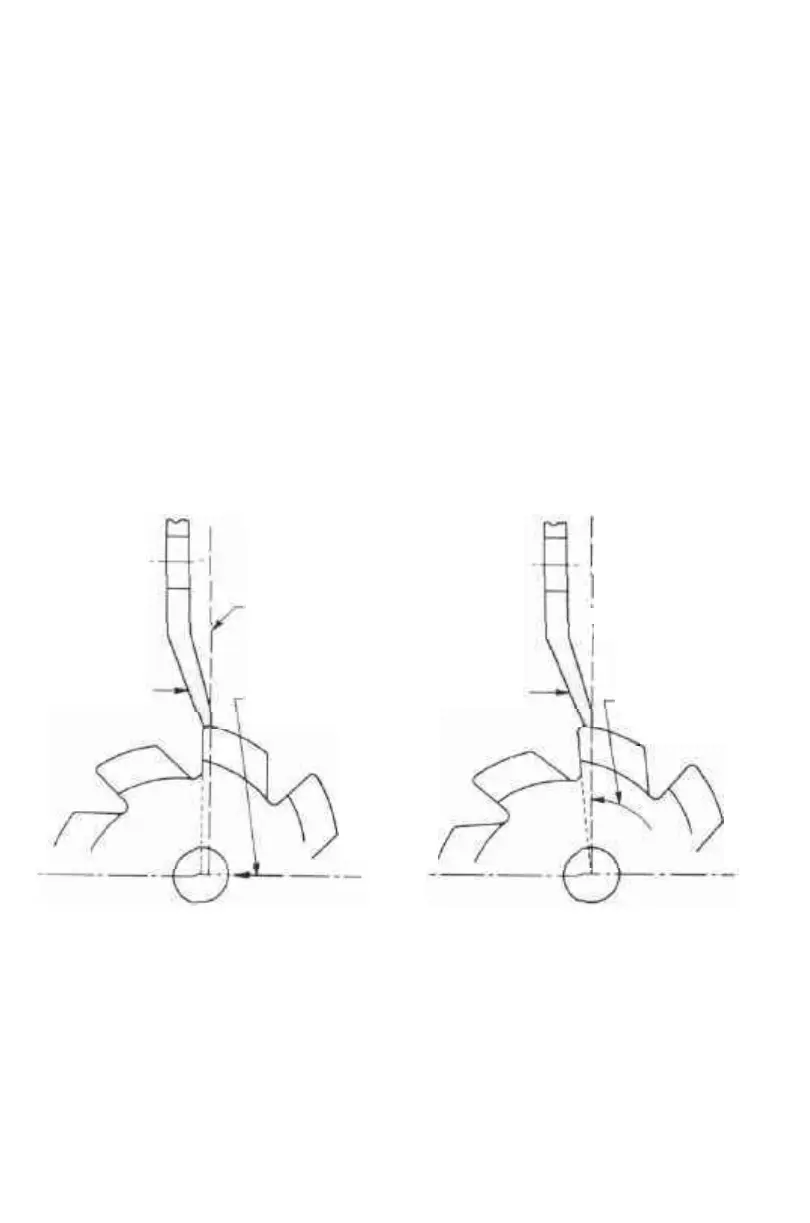

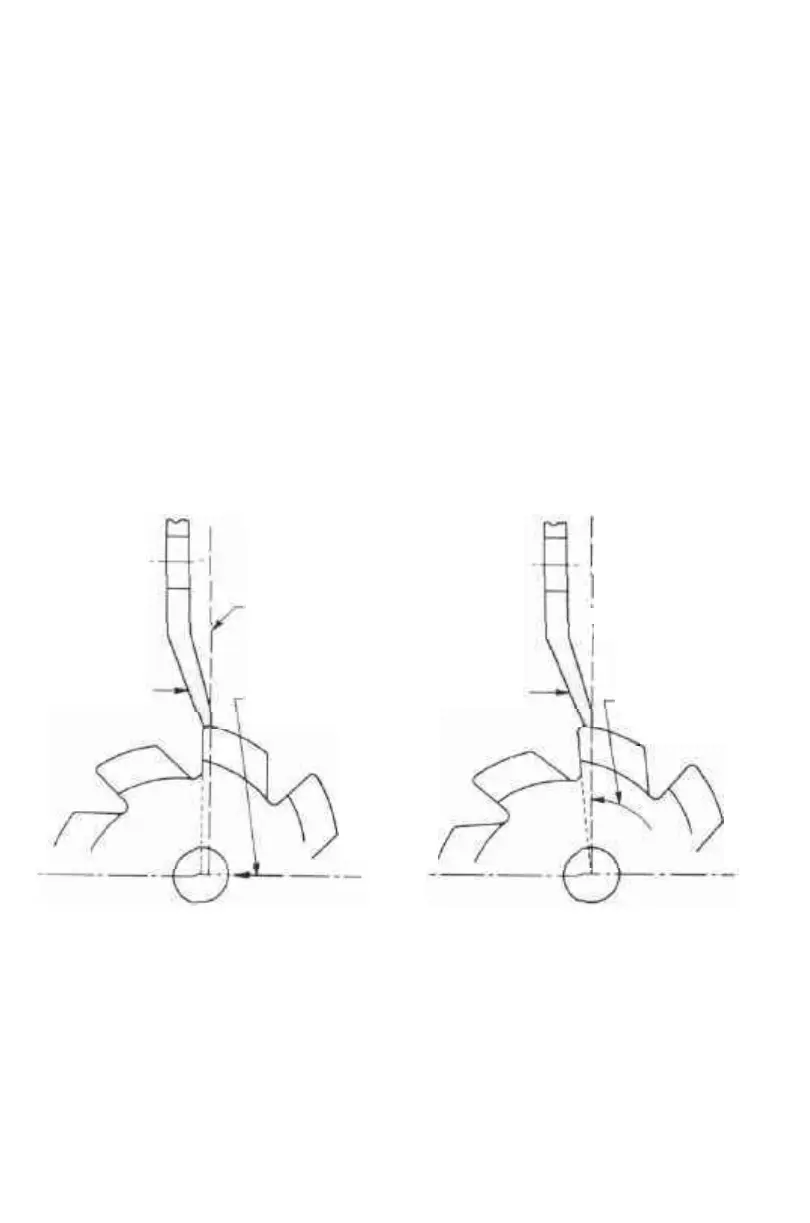

Form relieved cutters are sharpened by grinding the teeth faces as pictured in

Photos 37, 38, 39, 40, 41, 42 Figure 37A shows the correct and incorrect way to

GRINDING

WHEEL

LINE PARALLEL TO RADIUS

ON WHICH TOOTH IS

INCORRECTLY GROUND

LINE OF ADJUSTMENT

OF WORK TO

GRINDING WHEEL

GRINDING

WHEEL

RADIUS ON WHICH

TOOTH IS

CORRECTLY GROUND

LINE OF ADJUSTMENT

OF WORK TO

GRINDING WHEEL

WRONG

Figure 37A

RIGHT

sharpen these cutters. On K. 0. Lee grinders, the usual method of grinding these

cutters is to place them between centers, sharpening them with a saucer wheel.

Certain formed cutters, such as Fellows gear shaper cutters, are sharpened by

rotating them in with a motorized workhead. This process is described at the end

of the chapter. New form relieved cutters should have the backs of the teeth ground

prior to using these surfaces for indexing with a toothrest. This is done for the pur-

pose of creating indexing points on the cutter teeth which are equally distant from

the center of the cutter as well as to provide teeth backs which are parallel with any

axial helix that may exist on long cutters. From the foregoing, it can be seen that

—48—

Loading...

Loading...