CLEANING

After uncrating, remove protective coating from

all bright surfaces with a soft cloth moistened

with kerosene. Do

not

use acetone, gasoline or

lacquer thinner

-

these will damage painted

surfaces.

To prevent rust, wax the table with

paste wax.

INSTALLATION

The most accurate and vibration-free operation

will require the machine to be bolted to the

floor.

While this is not absolutely necessary, it

is highly recommended. The drill press should

be level and

rest solidly on the floor.

Place

shims under the three bolt holes to level the

drill press.

Equal pressure should be applied to

all three nuts when tightening to prevent

distorting the base.

RAISING HEAD

The drill press head is lowered on the column

to ease crating and transportation.

Before

operating the drill press, the head will need to

be raised to the operational level:

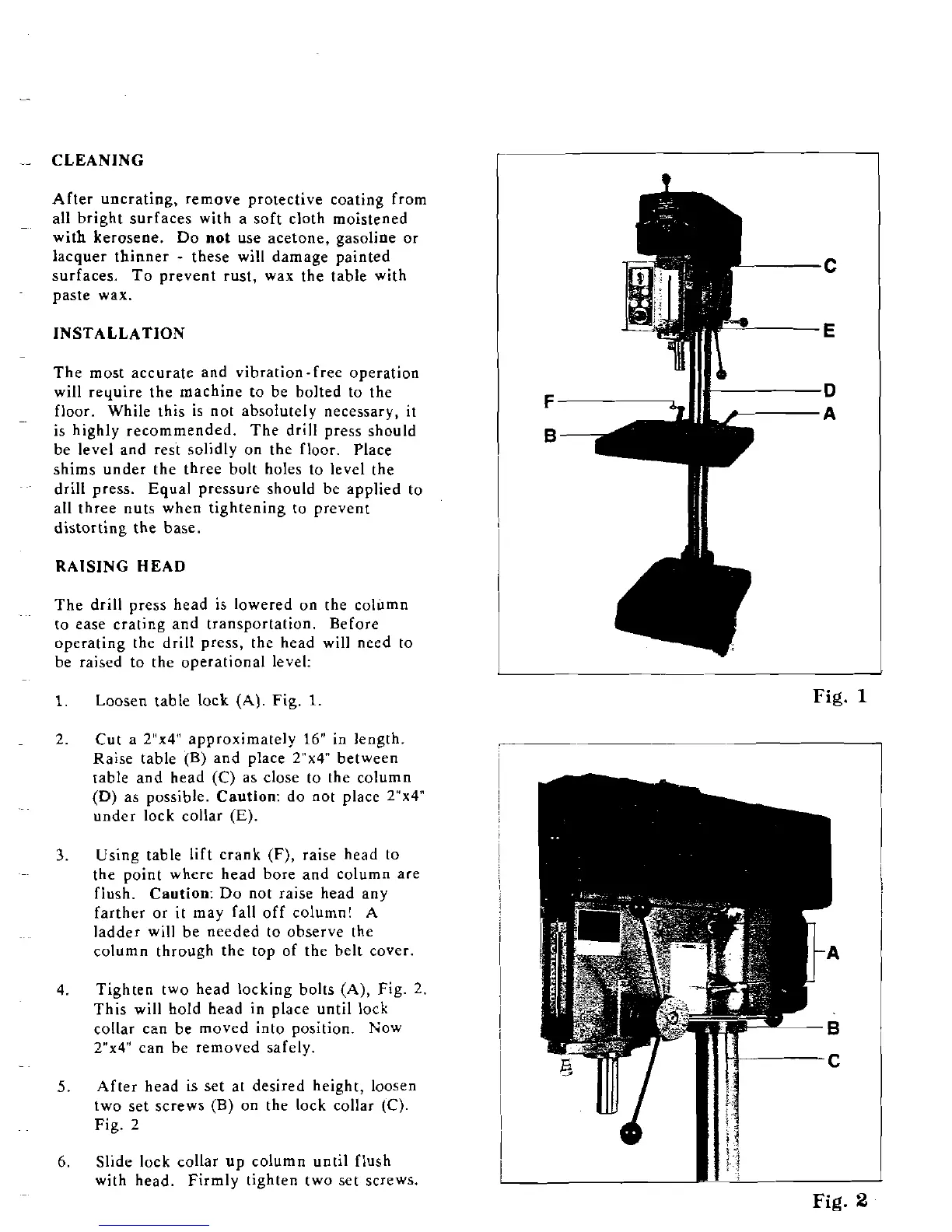

1.

Loosen table lock

(A).

Fig.

1

2.

Cut a

2"x4" approximately

16"

in length.

Raise table (B) and place

2"x4 between

table and head

(C)

as close to the column

(D)

as possible. Caution: do not place Z"x4"

under lock collar

(E).

3.

Using table lift crank (F), raise head to

the point where head bore and column are

flush. Caution: Do not raise head any

farther or it may fall off column!

A

ladder will be needed to observe the

column through the top of the belt cover.

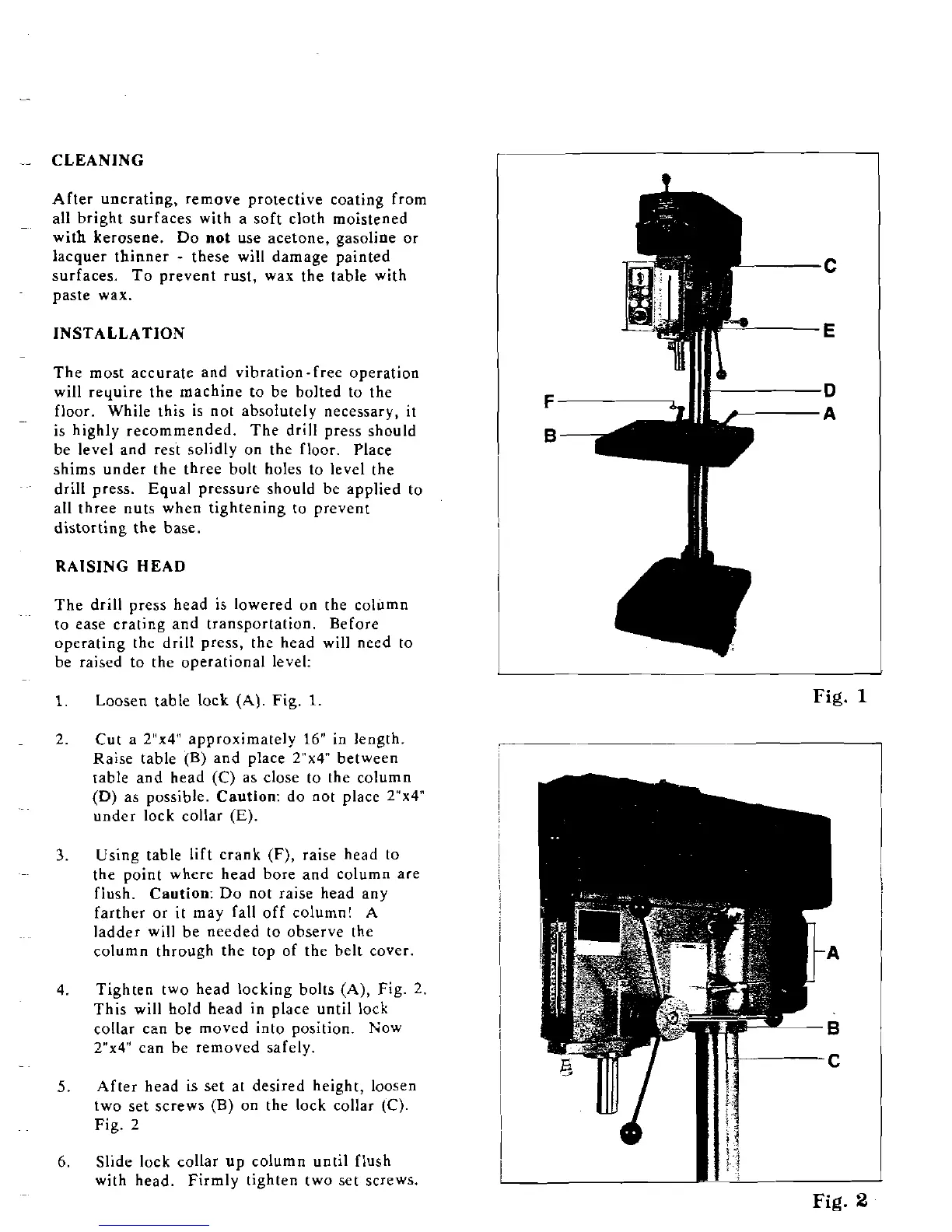

4.

Tighten two head locking bolts (A), Fig. 2.

This will hold head in place until lock

collar can be moved into position. Now

Z"x4" can be removed safely.

5.

After head is set at desired height, loosen

two set screws (B) on the lock collar

(C).

Fig. 2

6.

Slide lock collar up column until flush

with head.

Firmly tighten two set

scrcws.

1

Fig.

Fig.

Loading...

Loading...