CHANGING SPINDLE SPEEDS

CAUTION!

Do not turn handwheel control unless motor is

running. The speed control linkage will be

damaged

if

the motor is not running.

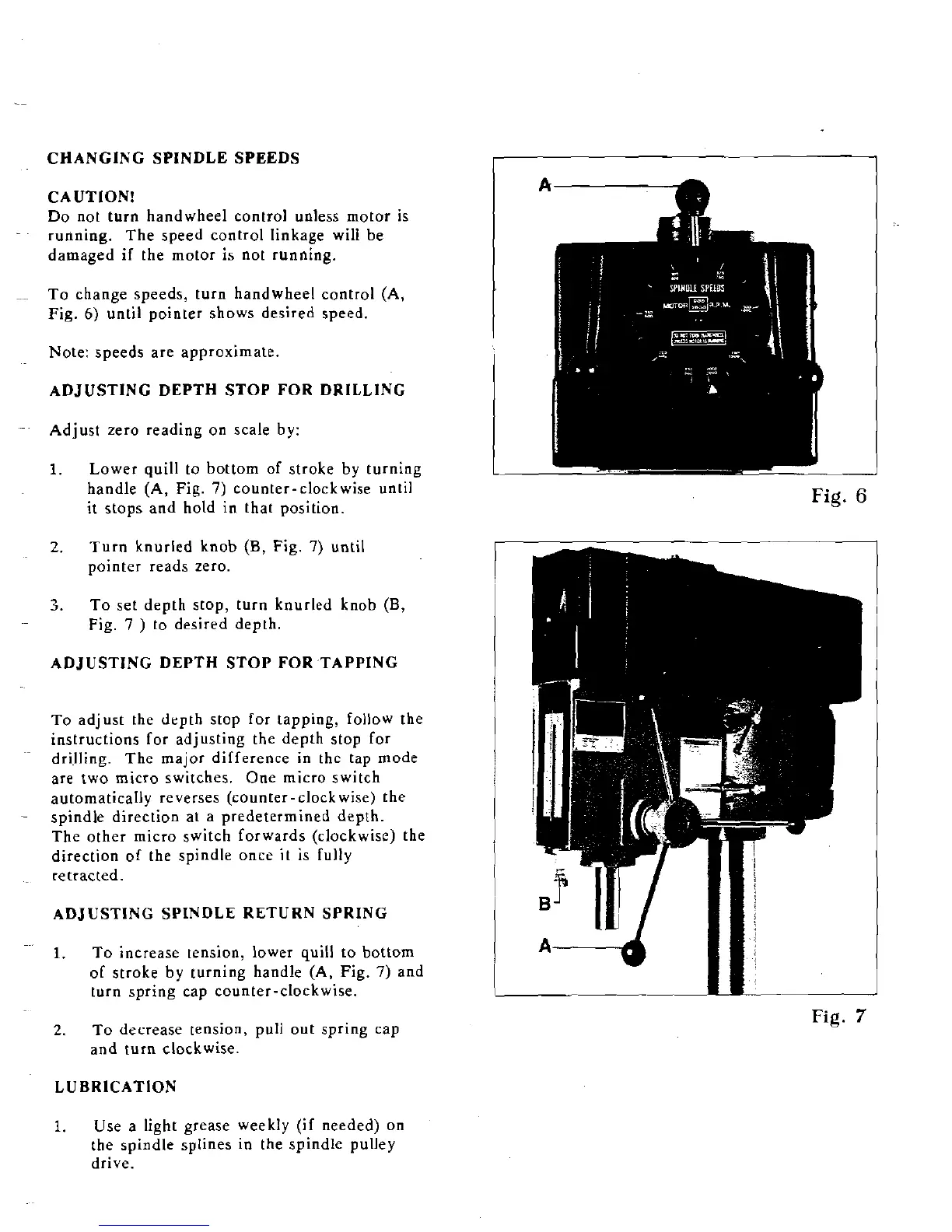

To change speeds, turn handwheel control (A,

Fig.

6)

until pointer shows desired speed.

Note: speeds are approximate.

ADJUSTING DEPTH STOP FOR DRILLING

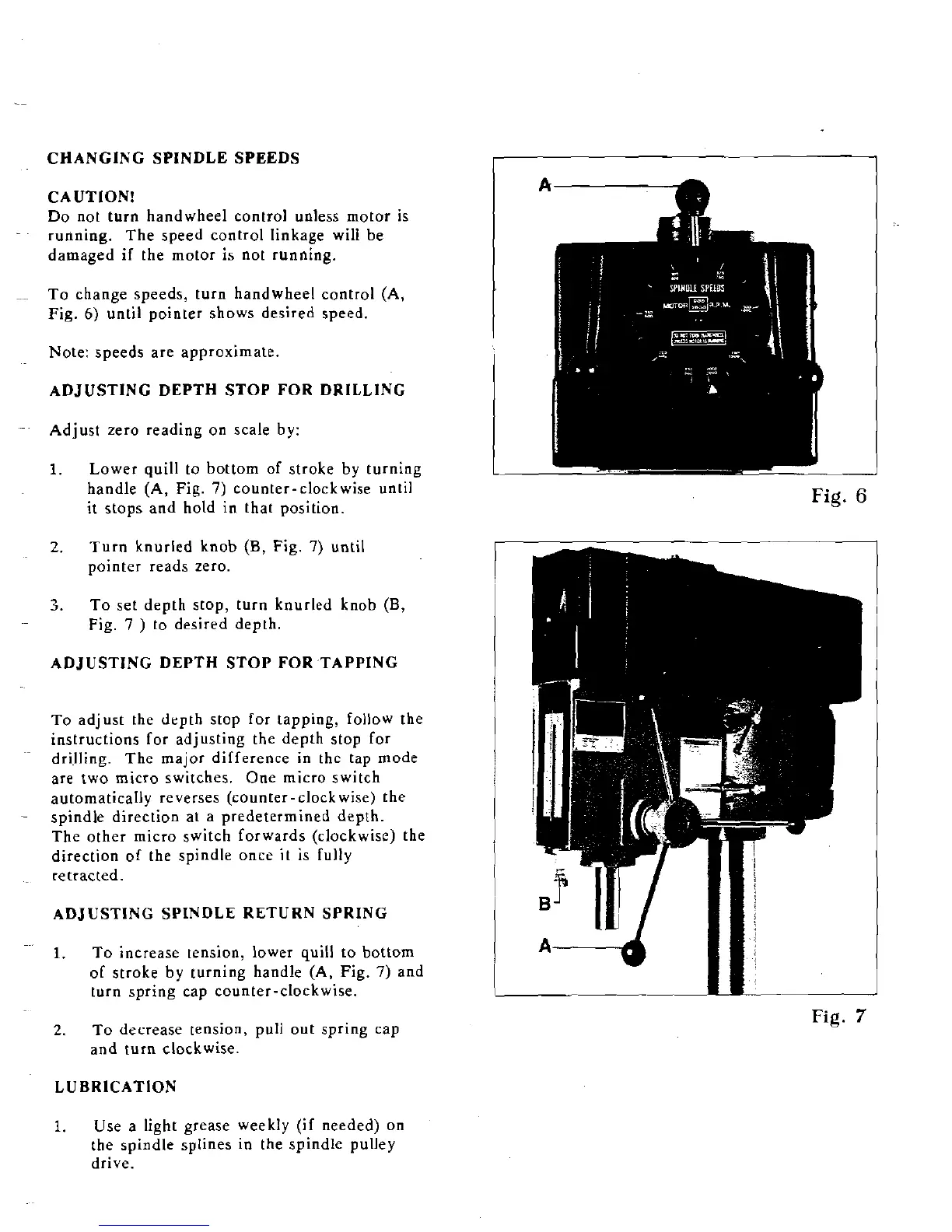

Adjust zero reading on scale by:

1.

Lower quill to bottom of stroke by turning

handle (A, Fig. 7) counter-clockwise until

it stops and hold in that position.

2.

Turn knurled knob

(B,

Fig.

7)

until

pointer reads zero.

3.

To set depth stop, turn knurled knob

(B,

Fig. 7

)

to desired depth.

ADJUSTING DEPTH STOP FORTAPPING

To adjust the depth stop for tapping, follow the

instructions for adjusting the depth stop for

drilling. The major difference in

thc tap mode

are two micro switches.

One micro switch

automatically reverses (counter-clockwise) the

spindle direction at a predetermined depth.

The other micro switch forwards (clockwise) the

direction of the spindle once it is fully

retracted.

ADJUSTING SPINDLE RETURN SPRING

1.

To increase tension, lower quill to bottom

of stroke by turning handle (A, Fig.

7)

and

turn spring cap counter-clockwise.

2.

To decrease tension, pull out spring cap

and turn clockwise.

LUBRICATION

Fig.

6

Fig.

7

1.

Use a light grease weekly (if needed) on

the spindle splines in the spindle pulley

drive.

Loading...

Loading...