1021 | 1022 SMALL AIR COMPRESSOR

06

1. Plug the power cord to the appropriate power supply.

Within the rst 10 seconds, the software version will display “1.23,”

followed by the air tank pressure, sequentially.

Example: 85 psig will display as 8-5 [pause]

2. Slowly purge the air tank until the motor powers ON.

3. Allow the air tank to ll (approximately 2–5 minutes).

4. Check for gauge display to reach between 118–120 psig

(8.14–8.27 bar).

TEST PASS:

• The software will automatically power OFF the motor when

the display reads between 118–120 psig (8.14–8.27 bar).

• No air leaks detected.

TEST FAIL:

• The motor does not power OFF when the display reads

between 118–120 psig (8.14–8.27 bar).

• An air leak detected.

• An error buzz sound and error code displays (

“E-r-#”

).

If the test fails, make note of the error code (if present)

and disconnect the power cord from the power supply to

power OFF. Refer to the troubleshooting section (page 8)

for possible corrective action and perform the Test Run

procedure again. If failure persists, contact your Keiser

dealer, distributor, or Keiser Customer Support (see front

cover for contact information).

Air compressor maintenance shall only be performed by

Keiser-certied technicians.

1. Plumbing: Connect a 1/4-inch quick-disconnect (QD) from

the Keiser equipment to any one of the ve QD ports.

A 3/8-inch compression tting port is also available for

3/8-inch air supply congurations (Tools: Adjustable

Wrench and 5/8-inch Wrench).

2. Power Cord: Connect the power cord to the power

connector.

3. Proceed to the Test Run section.

ASSEMBLY

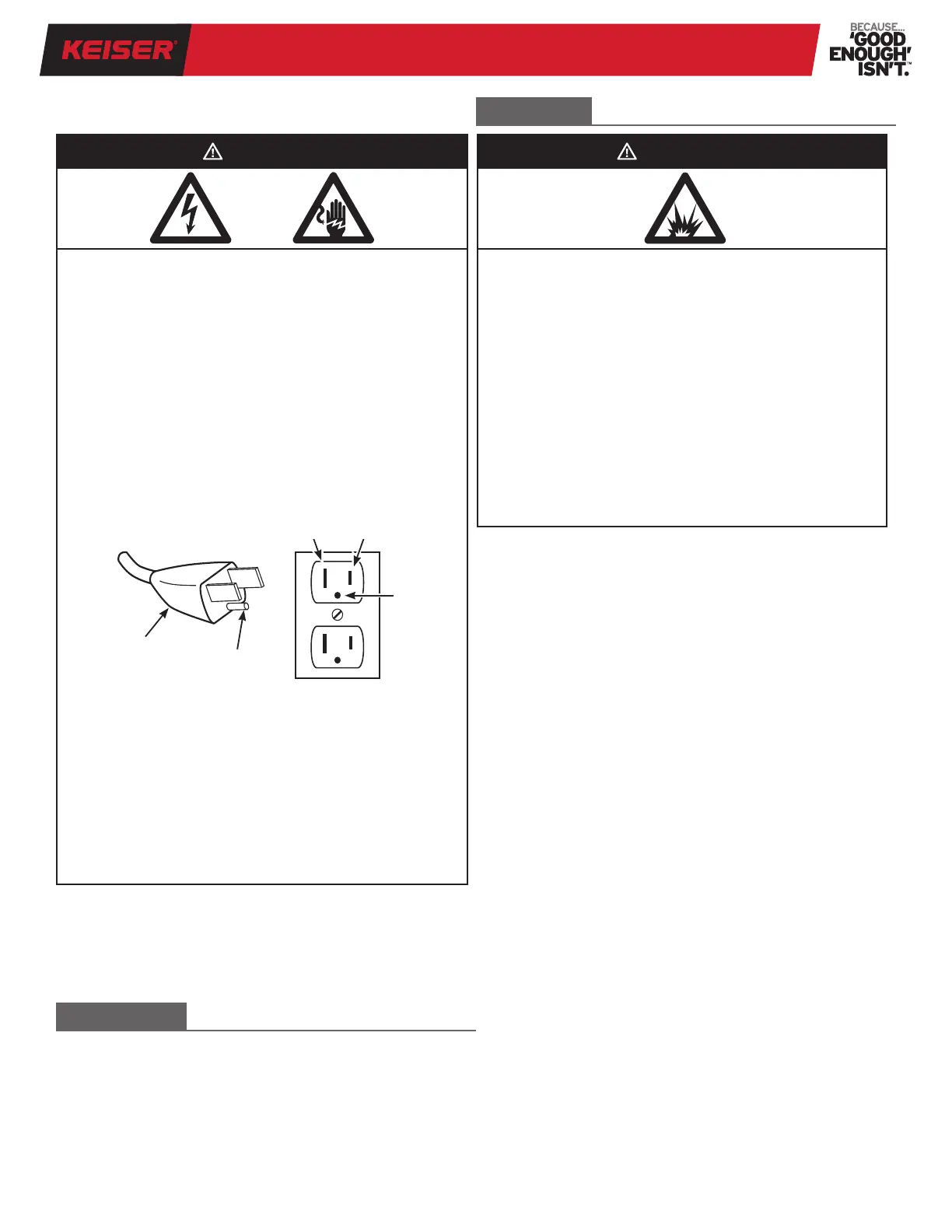

ELECTRIC SHOCK HAZARD

• Install this product where it will not come into contact with

water or other liquids.

• Ensure the power cord is free of damage before connecting

to the power supply.

• If the power cord is damaged, or shows signs of excessive

wear, stop use of the equipment immediately. Do not use

the equipment until the power cord is replaced. Only use

power cords provided by Keiser Corporation.

• This product must be properly grounded. For 120-volt or

220/240-volt circuits, connect power supply cord grounding

plug to a matching grounded outlet. Do not use an adapter

(See diagram below).

• The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

• Do not modify the power cord provided. Check with a qualied

electrician or serviceperson if grounding instructions are

not completely understood.

• Failure to follow these instructions can result in death, re

or electrical shock.

Grounded

Plug

120-volt grounded connectors shown.

220/240-volt grounded connectors will differ in shape.

Grounding

Pin

Grounded

Outlet

Neutral Hot

DANGER

ELECTRICAL POWER REQUIREMENTS

Before using the air compressor, check that supply voltage

agrees with that listed on product serial number label or

refer to the Equipment Specications section (page 4).

Low voltage or an overload circuit can cause the overload

protection system circuit breaker to trip.

WARNING

EXPLOSION HAZARD

• Exercise caution when using pressurized air.

• Only use hoses and air ttings provided by the manufacturer.

• Inspect all hoses and ttings for leaks or wear. If leaks or

wear are detected, stop use and replace parts immediately.

Do not use until repairs have been completed and tested

by a Keiser-certied technician.

• Never leave pressurized air in the air tanks when storing

the air compressor or during downtime (maintenance).

• If the air tank develops a leak, replace the air tank

immediately. Never repair, weld or make modications to

the air tanks or their attachments.

• Never make adjustments to the factory-set pressures.

TEST RUN

Loading...

Loading...