Page 9

8) Refrigerant circuit controls

A) Liquid refrigerant injection: The liquid refrigerant is into the evaporator by a control valve. This valve is a

thermostatic or pressostatic one maintaining a constant overheats of the refrigerant in the evaporator(s).

B) Constant evaporating pressure: In the dryers equipped with a by-pass valve, the evaporating pressure is

kept constant by a controlled injection of hot gas from the high-pressure side into the low-pressure

section of the circuit.

9) Condensate drain - trap assembly

Dismantling the drain is easy because it can be isolated from the air circuit under pressure with a ball valve.

The drain has to be depressurized before being dismantled.

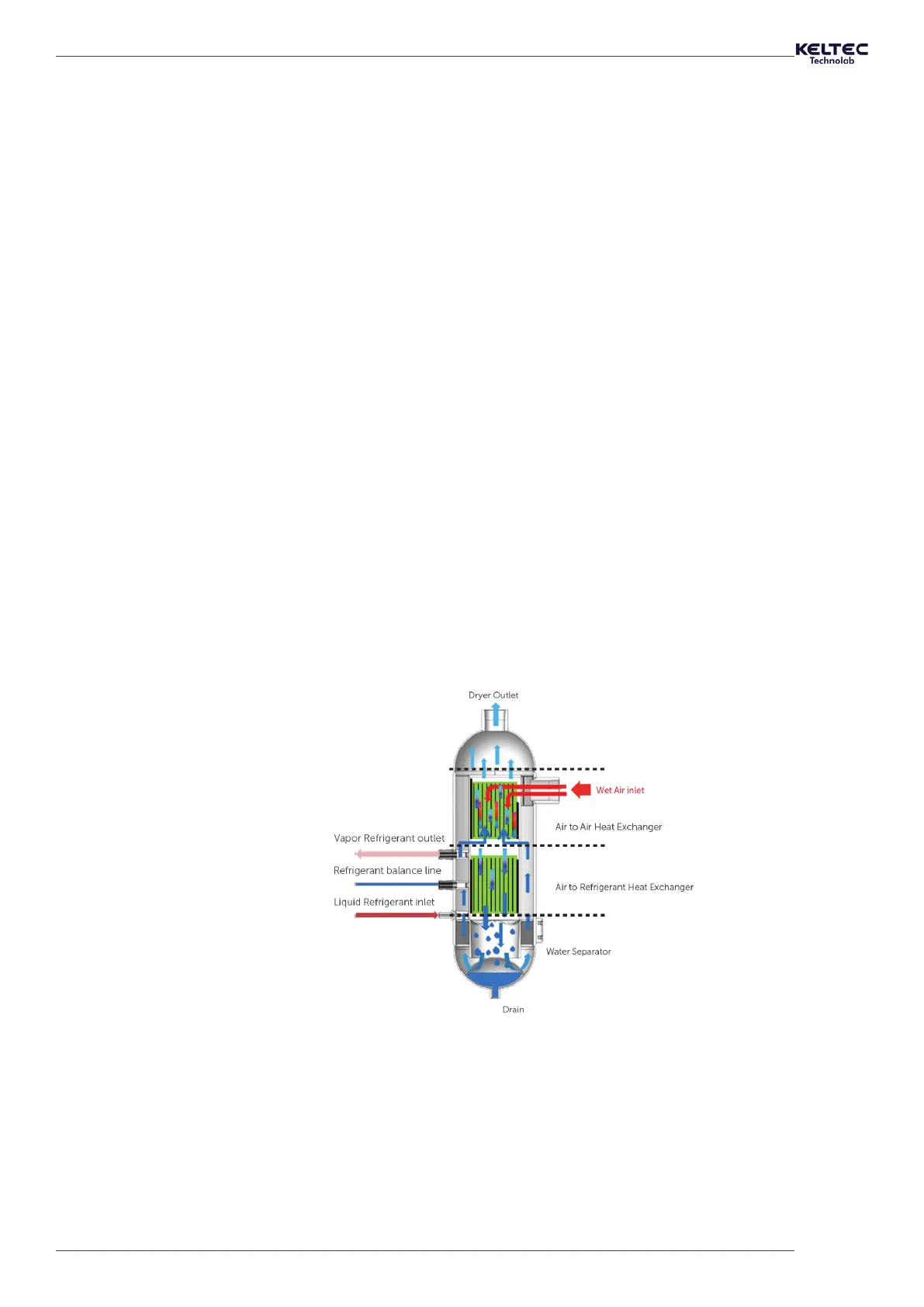

10) Heat Exchanger Modular design

A The dryers are equipped with a compact Mono Bloc Heat Exchanger module.

This assembly has been specially designed to dry compressed air and is made of:

1 An Economiser which pre-cools the entering hot air with the out flowing cold air.

2 An air / Thermal mass refrigerant exchanger cooling down the compressed air.

3 A centrifugal separator concentrating all condensates and requiring no maintenance.

Air Cooled

System

Loading...

Loading...