FastMig MS 200, MS 300

10

EN

NOTE! In crater ll, the initial value of the welding power must be greater than the nal

value, and therefore the adjustment ranges for the initial and nal values are restricted

automatically, if necessary.

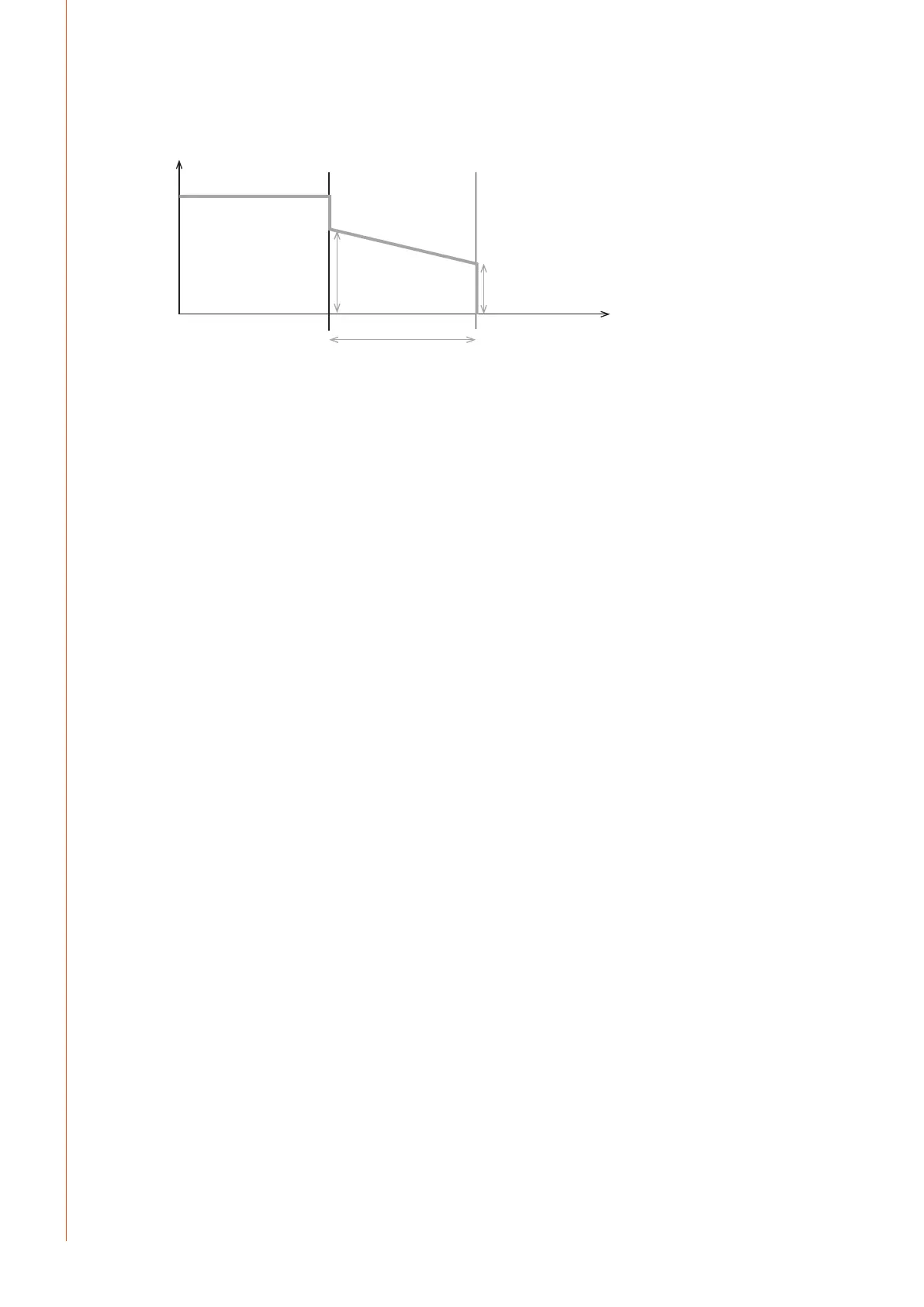

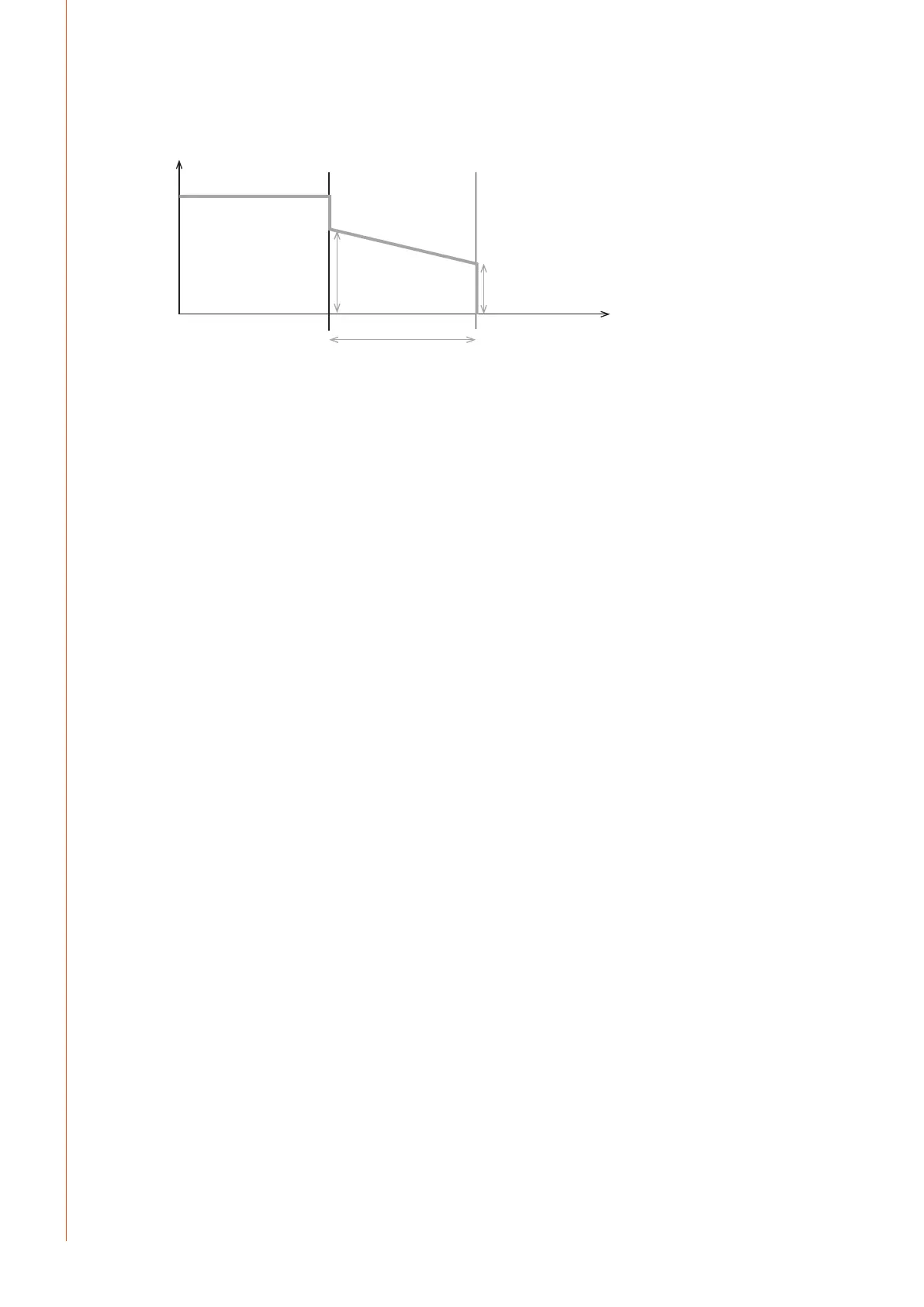

Welding Level

Crater Fill Start Level

Crater Fill Time

Crater Fill End Level

Parameters related to these functions are set via the SETUP function (see ’SETUP functions’).

Stopping is performed as with the normal 4T function.

The values of parameters related to additional MIG functions can be changed with the SETUP

function (see ’SETUP’).

Parameters are selected for adjustment via potentiometer on the left. The value of the

parameter is set via potentiometer on the right. The value is immediately recorded in the

memory.

Activation through SETUP

Other additional MIG functions are activated through SETUP.

• Creep Start is meant to facilitate the initial weld – e.g., when welding with a high wire

feed speed. The wire feed speed is kept low until the wire touches the work piece and

the current begins to ow. Creep Start can be selected with normal MIG welding or with

Synergic 1-MIG welding.

• WiseFusion™ is a welding function for ensuring consistent weld quality in all positions.

It is an optional feature, which can be purchased through Kemppi DataStore.

• WisePenetration™ is a welding function for delivering constant welding power

regardless of changes in the stick out length. It is an optional feature, which can be

purchased through Kemppi DataStore.

• MatchLog™ contains MiniLog™ function for quickly changing welding parameters on

the run. It is an optional feature, which can be purchased through Kemppi DataStore.

• If your welding needs change and you wish to update your system in the future, you can

order additional welding programs or other welding software and load them to your

system with Kemppi DataGun eld programming device.

For further information about the available welding programs, modied processes and special

enhanced arc performance solutions, visit Kemppi web site at www.kemppi.com or contact

the local Kemppi dealer.

Loading...

Loading...