TECH SHEET - DO NOT DISCARD PAGE 7

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10035270

12. Plug in dryer or reconnect power.

13. Perform the Console Buttons and

Indicators Diagnostic test, page 1, to

verify repair.

14. If indicators still do not light, the

machine control electronics has failed:

➔

Unplug dryer or disconnect power.

➔

Replace the machine control

electronics.

➔

Plug in dryer or reconnect power.

➔

Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

TEST #2 Machine Control

Power Check

This test is used to determine if power is

present at the machine control electronics.

NOTE: The drum light is controlled by the

machine control on all models.

1. Plug in dryer or reconnect power.

2. Open the door.

➔

If the drum light illuminates, then

power is present at the machine

control. Go to TEST #6, page 10.

➔ If the drum light fails to illuminate,

do not assume the machine control

electronics needs replacement.

Several conditions may cause the

drum light not to illuminate, including

a bad bulb. If the drum light does not

illuminate, go to TEST #1, page 6.

TEST #3a Drive Motor Circuit

This test will check the wiring to the motor

and the motor itself. The following items are

part of this motor system:

–

Harness/

connection

–

Thermal fuse

–

Belt/belt switch

–

Drive motor

–

Centrifugal switch

–

Door switch

–

Machine control

electronics. See

ESD information,

page 1.

1. Unplug dryer or disconnect power.

2. Access the machine control electronics

and measure the resistance across P8-4

and P9-1. See Accessing & Removing the

Electronic Assemblies, page 11.

➔

If resistance across P8-4 and P9-1 is in

the range of 1 to 6 ohms, replace the

machine control electronics.

➔

Otherwise, go to step 3.

3. Check the wiring and components in the

path between these measurement points

by referring to the appropriate wiring

diagram and strip circuit, pages 4 and 5.

4. Check the thermal fuse. See TEST #4b,

page 9.

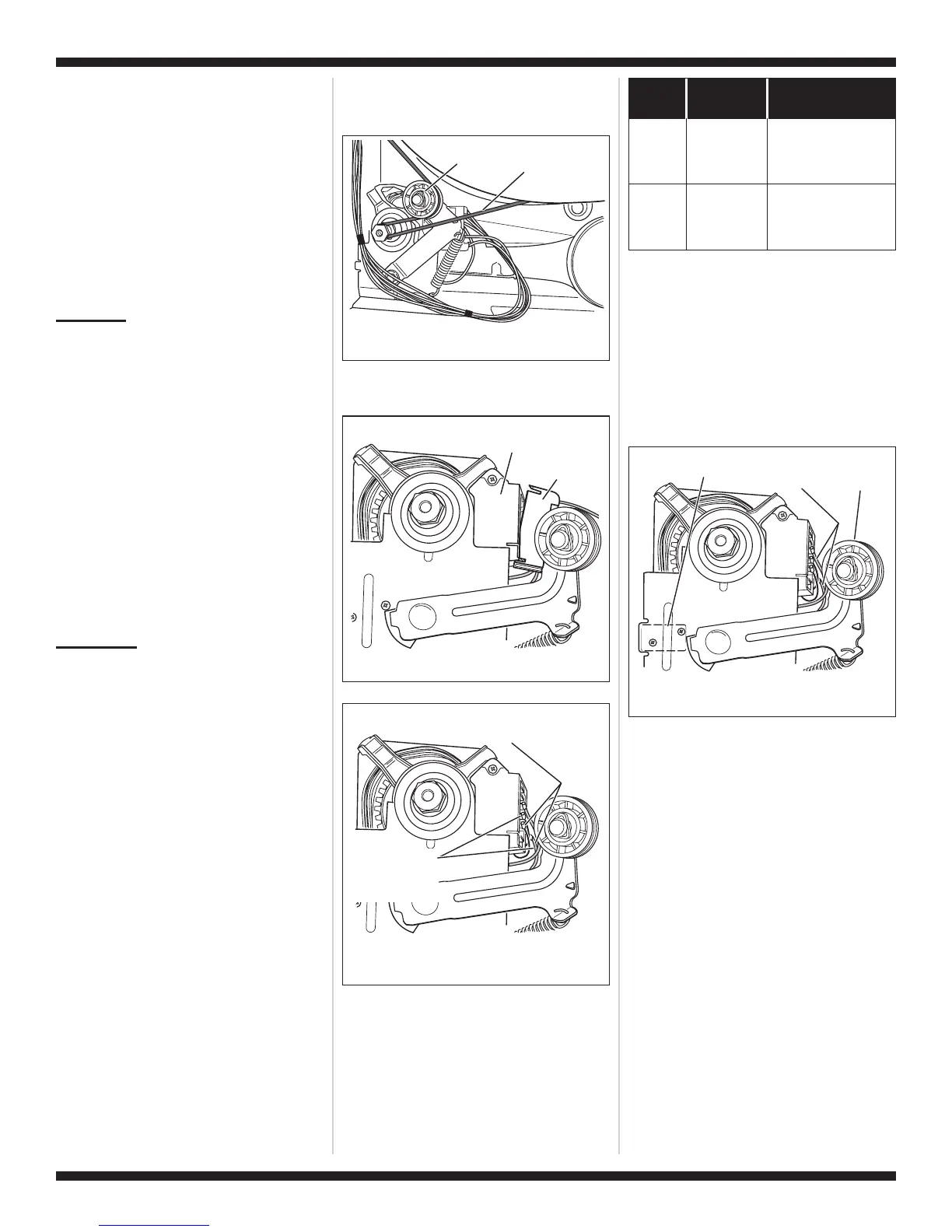

5. Check the belt switch and drive motor.

Access the belt switch and drive motor by

removing the back panel. See Removing

the Back Panel, page 12. Slowly remove

the drum belt from the spring-loaded belt

switch pulley, gently letting the belt switch

pulley down. See figure 5.

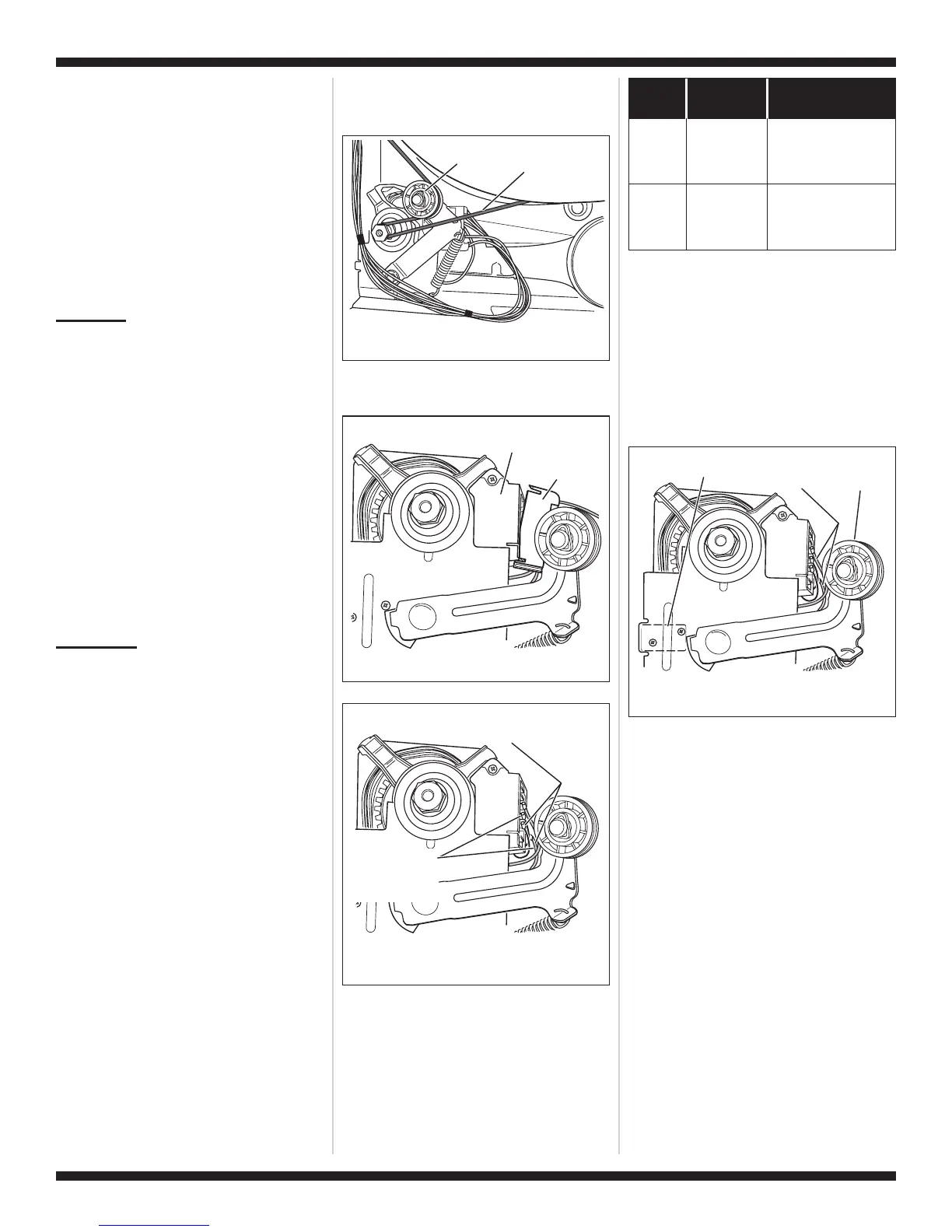

6. Remove the white connector from the

drive motor switch. See figure 6.

7. Using figure 7, check for the resistance

values of the motor’s Main and Start

winding coils as shown in the following

table.

NOTE: Main and Start winding coils must

be checked at the motor.

WINDING RESISTANCE

Ω

CONTACT POINTS OF

MEASUREMENT

MAIN

1.4–2.6

Blue wire in back at

pin 4 and bare copper

wire on pin 5 of black

drive motor switch

START

1.4–2.8

Blue wire in back at

pin 4 and bare copper

wire on pin 3 of black

drive motor switch

➔

If the resistance at the motor is correct,

there is an open circuit between the

motor and machine control

electronics. Check for failed belt

switch.

➔

If the Start winding resistance is much

greater than 4 ohms, replace the motor.

8. Check the belt switch by measuring

resistance between the two blue wires as

shown in figure 8, while pushing up the

belt switch pulley.

➔

If the resistance reading goes from

infinity to a few ohms as pulley arm

closes the switch, belt switch is OK.

If not, replace the belt switch.

➔

If belt switch is OK and there is still an

open circuit, check and repair the

wiring harness.

9. Door switch problems can be uncovered

in the Door Switch Diagnostic Test, page 1;

however, if this was not done, the

following can be done without applying

power to the dryer. Connect an ohmmeter

across P8-3 (neutral, white wire) and P8-4

(door, tan wire).

➔

With the door properly closed, the

ohmmeter should indicate a closed

circuit (0–2 ohms).

➔

If not, replace the door switch

assembly. See figure 12, page 11; and

Removing the Front Panel/Drum

Assembly, page 11.

Drum

Belt

Tension

Pulley

Figure 5. Slowly remove drum belt.

2

6

4

3

5

1

Drive Motor

Switch

White

Connector

Figure 6. Remove white connector.

2

6

4

3

5

1

Main Winding:

and Bare Copper Wire (5 position)

Blue Wire in Back

Start Winding:

Blue Wire in Back

and Bare Copper

Wire (3 position)

Figure 7. Main and start winding

measure points.

2

6

4

3

5

1

Belt Switch

Tension

Pulley

Blue Wires

(Back and 4 position)

Figure 8. Checking the belt switch.

Loading...

Loading...