FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10035270

TECH SHEET - DO NOT DISCARD PAGE 8

TEST #3b Blower Motor (Dual

Motor Model)

1. Access the motor control electronics. See

Accessing & Removing the Electronic

Assemblies, page 11.

2. Visually check the communication har

-

ness. See figure 15, page 12. The com

-

munication harness is a three-wire har-

ness that connects between the two elec-

tronic control assemblies. Make sure it is

fully inserted into both electronic controls.

3. If the communication harness looks OK,

go to step 4.

4. Visually check the wire harnesses

connected to the motor control electronic

assembly. Make sure they are clean and

fully inserted into the control.

➔

If the connections look OK, go to

step 5.

5. Remove the MC2 blower motor electrical

connector from the blower motor

electronic control.

6. Measure the resistance between the fol

-

lowing terminals on the connector: pins

1 to 3, 1 to 5 and 3 to 5. The resistance

should be between 55 and 65 ohms.

➔ If the resistance looks OK, go to

step 7.

➔ If the resistance is much greater than

65 ohms, go to step 7.

➔ If the resistance is much less than

55 ohms, replace the blower motor.

7. Visually check the wire harness

connection at the blower motor (See

Accessing the Blower Motor below).

➔ If the connections look OK, check for

obstructions in the blower housing.

Make sure blower fan rotates freely.

➔

If no obstructions are found, replace

the motor control electronic assembly.

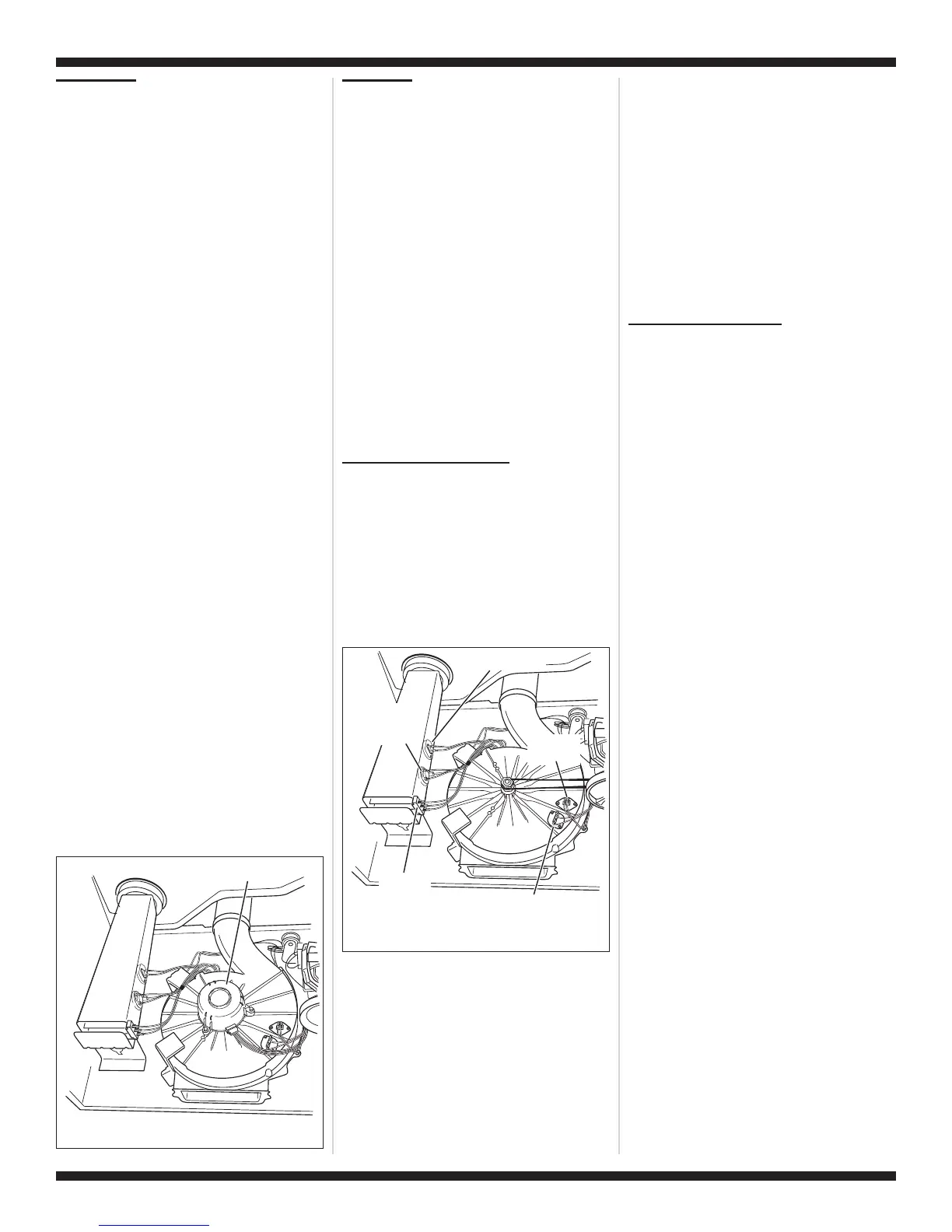

Accessing the Blower Motor:

Follow the steps under Removing the Front

Panel/Drum Assembly, page 11. The blower

motor is located on top of the blower

housing as shown in figure 9.

TEST #4 Heater

This test is performed when either of the

following situations occur:

✔

Dryer does not heat

✔

Heat will not shut off

This test checks the components making up

the heating circuit. The following items are

part of this system:

–

Harness/

connection

–

Heater relay

–

Thermal cut-off

–

Inlet thermistor/

high limit

thermostat

–

Heat element

assembly

–

Centrifugal switch

–

Exhaust thermistor

–

Machine control

electronics. See

ESD information,

page 1.

–

User interface

assembly

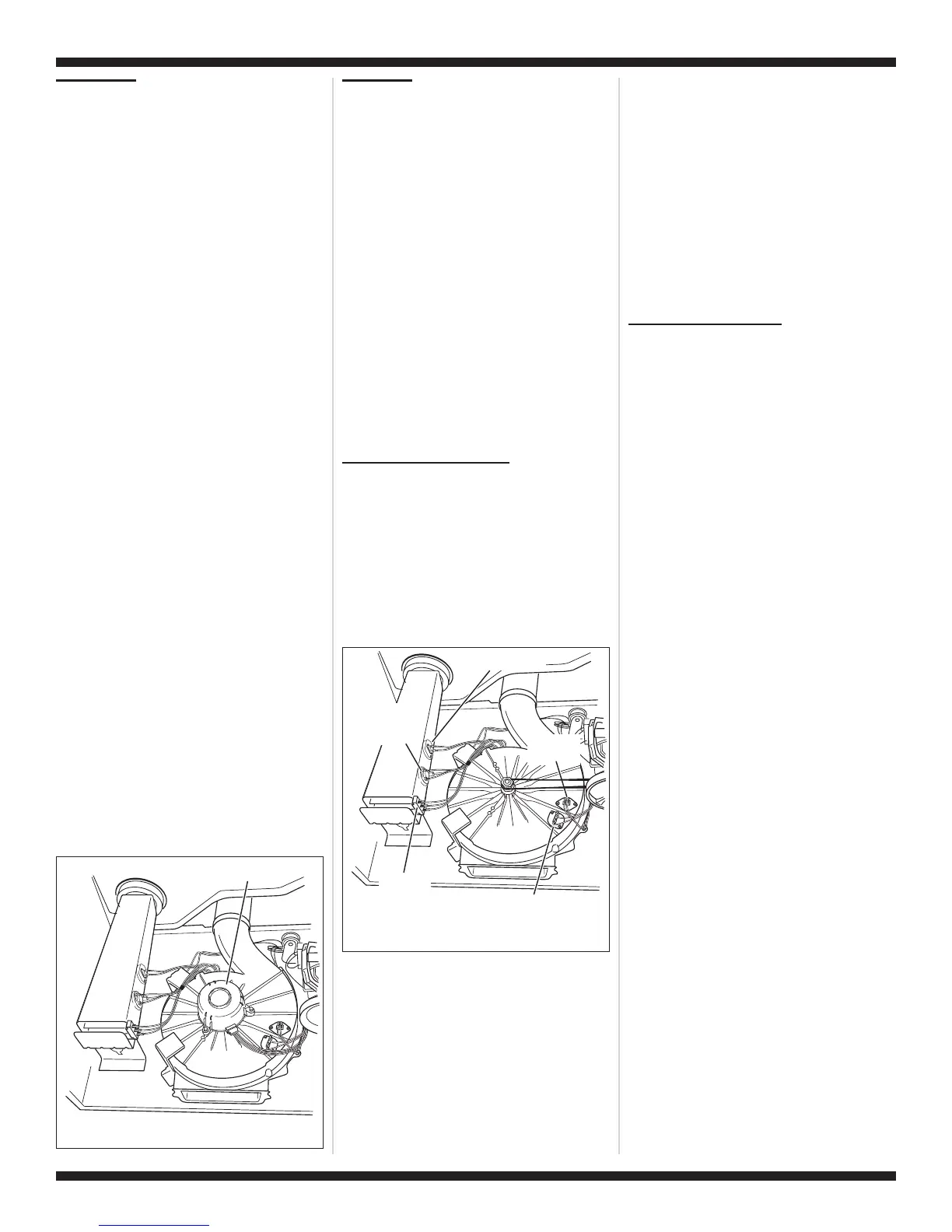

Dryer does not heat:

Locate the components using figure 2,

page 6; and figure 10.

SINGLE ELEMENT MODEL

:

1. Unplug dryer or disconnect power.

2. Remove the front panel and drum

assembly to access the thermal

components. See Removing the Front

Panel/Drum Assembly, page 11.

3. Using an ohmmeter and referring to the

appropriate wiring diagram and strip cir-

cuit, pages 4 and 5, measure the resis-

tance from the red wire terminal at the

thermal cut-off to the red wire terminal at

the heater.

➔

If the resistance is about 10 ohms, go

to step 5.

➔

If an open circuit is detected, go to

step 4.

4. Visually check the wire connections to the

thermal cut-off, high limit thermostat, and

heater. If connections look good, check

for continuity across each of these

components.

➔

Replace the heater if it is electrically

open.

➔

Replace both the thermal cut-off and

high limit thermostat if either one is

electrically open.

5. If no open circuit is detected, remove the

P4 connector, then measure the

resistance between P4-3 (red wire) and

P4-6 (red wire) at the connector. See

figure 16, page 12 for connector location;

and Accessing & Removing the

Electronic Assemblies, page 11.

➔

If 5–15 k ohms are measured, replace

the machine control electronics.

➔

If the resistance is less than 1 k ohm,

replace the thermistor.

DUAL ELEMENT MODEL

:

1. Unplug dryer or disconnect power.

2. Remove the front panel/drum assembly

to access the thermal components. See

Removing the Front Panel/Drum

Assembly, page 11.

3. Using an ohmmeter and referring to the

appropriate wiring diagram and strip

circuit, pages 4 and 5, measure the

resistance from the black wire terminal at

the thermal cut-off to the red wire terminal

at the high limit thermostat.

➔

If an open circuit is not detected, go to

step 5.

➔ If an open circuit is detected, go to

step 4.

4. Visually check the wires connections to

the thermal cut-off and the high limit

thermostat. If connections look good,

check for continuity across each of these

components. Replace both the thermal

cut-off and high limit thermostat if either

one is electrically open.

5. Measure the resistance between the red

wires at the heater.

➔

If an open circuit is not detected, go to

step 7.

➔

If an open circuit is detected, go to

step 6.

6. Visually check the wire connections to

the heater. If the connections look good,

replace the heater.

7. Measure the resistance at the heater

between the violet wire and the red wire

with the larger terminal.

➔

If an open circuit is not detected, go to

step 9.

➔

If an open circuit is detected, go to

step 8.

8. Visually check the wire connections to

the heater. If the connections look good,

replace the heater assembly.

9. If no open circuit is detected, remove the

P4 connector, then measure the

resistance between P4-3 (red wire) and

P4-6 (red wire) at the connector. See

figure 16, page 12 for connector location;

and Accessing & Removing the

Electronic Assemblies, page 11.

➔

If 5–15 k ohms are measured, replace

the machine control electronics.

Blower Motor

Figure 9. Blower motor location.

Thermal Fuse

Exhaust

Thermistor

Inlet Thermistor/

High Limit

Thermostat

Thermal Cut-Off

Heater

Element

Figure 10. Thermal components,

viewed from front.

Loading...

Loading...