EN

6

3 - PRELIMINARY CHECKS

Before installing the product, perform the following checks and in-

spections:

check that the gate, the door or the barrier is suitable for automation;

the weight and size of the gate or door and the balance of the barrier

boom must be within the operating limits specied for the automa-

tion system in which the product is installed;

check that the gate or door has rm, eective mechanical safety

stops;

make sure that the product xing zone is not subject to ooding;

high acidity or salinity or nearby heat sources might cause the pro-

duct to malfunction;

in case of extreme weather conditions (e.g. snow, ice, wide tempe-

rature variations or high temperatures), friction may increase, cau-

sing a corresponding rise in the force needed to operate the system;

the starting torque may therefore exceed that required in normal

conditions;

check that when operated by hand the gate, the door or the barrier

moves smoothly without any areas of greater friction or derailment

risk;

check that the gate, door or the barrier is well balanced and will the-

refore remain stationery when released in any position;

check that the electricity supply line to which the product is to be

connected is suitably earthed and protected by an overload and dif-

ferential safety breaker device;

the system power supply line must include a circuit breaker device

with a contact gap allowing complete disconnection in the condi-

tions specied by class III overvoltage;

ensure that all the material used for installation complies with the

relevant regulatory standards.

2.4 - List of cables required

• Electronic protection against short circuit and overload on the

FLASH, IND/ELEC and LED outputs

• Protection of 24VAC and PH-POW outputs via resettable fuses

• Automatic obstacle detection

• Auto-learning of travel length

• Disabling of unused safety inputs via dip switches: it is not

necessary to insert jumpers on the respective input terminals

(paragraph 4.2)

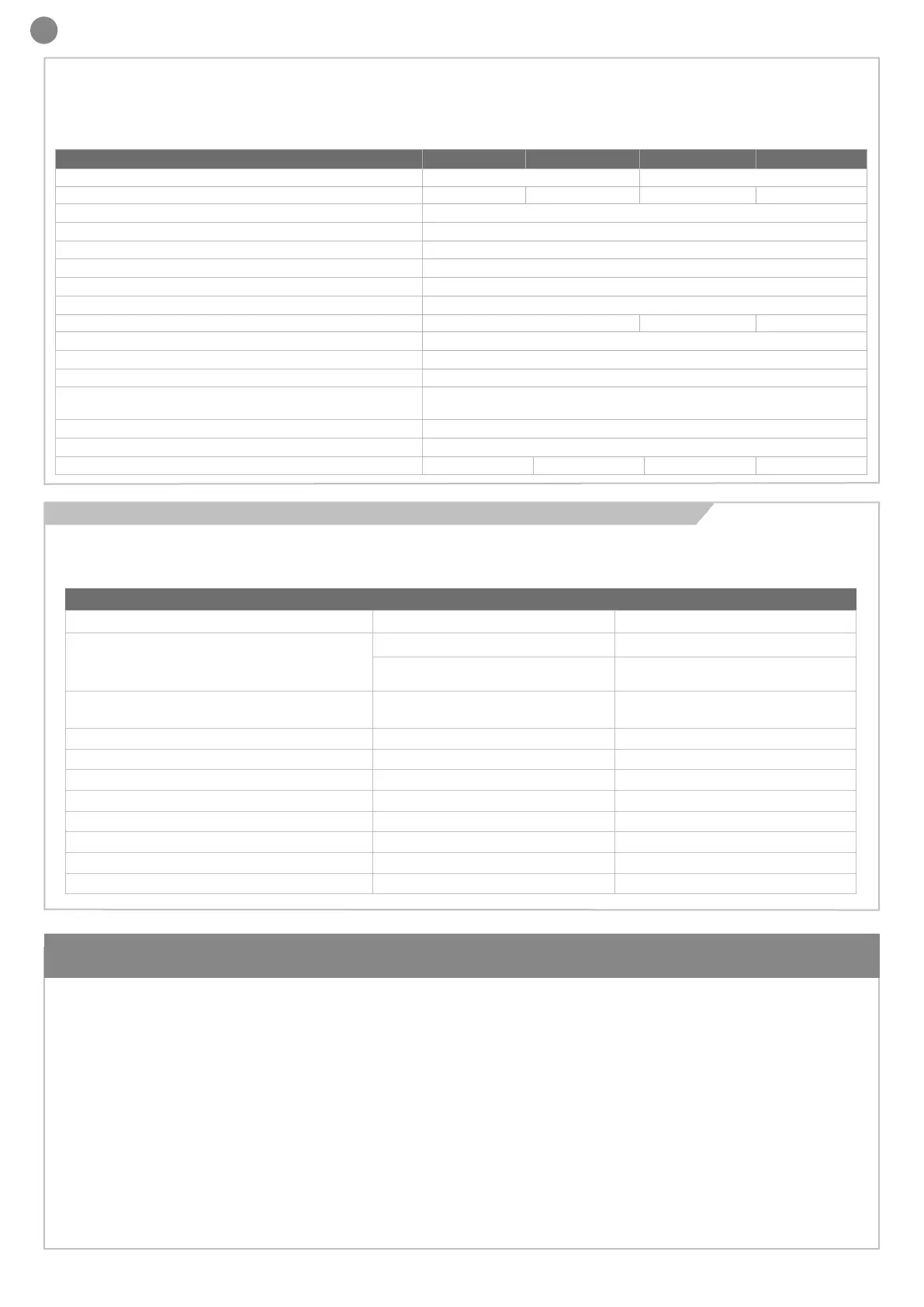

TECHNICAL SPECIFICATIONS CT20324 CT20324E CT20324L CT20324EL

Power Supply 230Vac (+10% - 15%) 50/60 Hz 115 Vac (+10% - 15%) 50/60 Hz

Nominal power

210W maximum 280W maximum 210W maximum 280W maximum

Maximum output current 24VAC 200 mA (24 VAC)

PH-POW maximum output current 250 mA (24 VDC non-regulated)

Maximum FLASH output power 15 W (24 VDC)

Maximum LED output power 15 W (24 VDC)

Maximum power for the “IND/ELEC” output 5 W (24 VDC) / 15 VA (12 VDC)

Accessory fuses 2.0 AT (timed)

Power line fuses 1.6 AT 3 AT 5 AT

Integrated radio receiver 433.92 MHz OOK

Antenna wire or cable antenna RG58

Number of saved transmitters 150

Can be used in saline, acidic or explosive atmosphere

environments

NO

IP protection class IP54

Overall dimensions 222 x 110 x 275 H mm

Weight 3,87 kg 4,46 kg 3,87 kg 4,46 kg

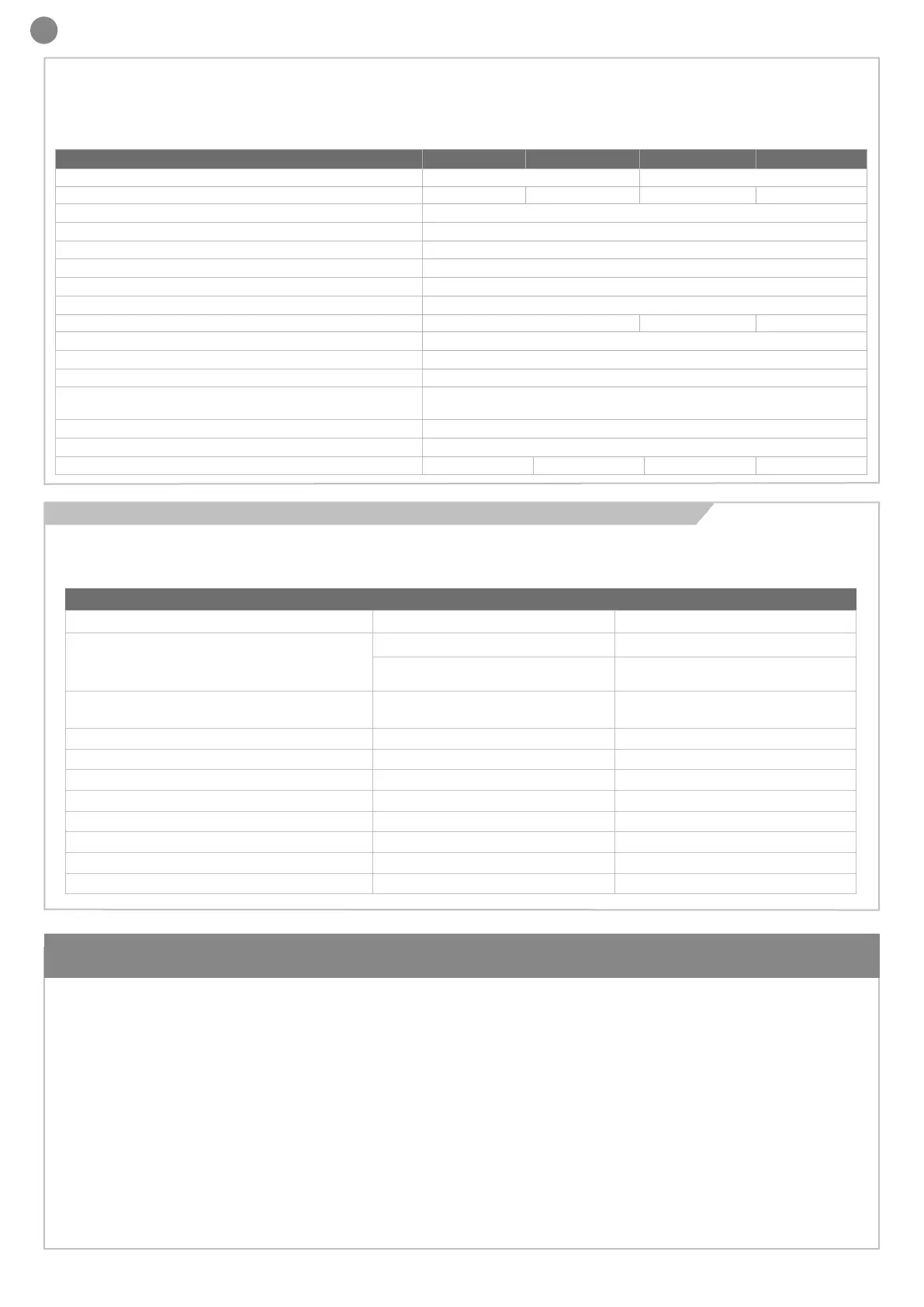

ELECTRIC CABLE TECHNICAL SPECIFICATIONS

CONNECTION CABLE MAXIMUM PERMITTED LIMIT

Control unit power transformer input

3 x 1,5 mm² if less than or equal to 20 m

3 x 2,5 mm²

if greater than 20m, (connect the earth

wire near the control unit)

Flashing light (FLASH)

Courtesy light (LED)

3 x 0.55 mm² 20m

Antenna RG58 cable 10 m (recommended < 5 m)

Electric locking (IND/ELEC) 2 x 1.5 mm² 10m

Photocells (transmitter) 2 x 0.55 mm² 20m

Photocells (receiver) 4 x 0.55 mm² 20m

Safety edge 2 x 0.55 mm² 20m

Key switch 4 x 0.55 mm² 20m

Motors power supply (M1 and M2) 2 x 1.5 mm² 10m

Encoder cables 4 x 0.55 mm² 10m

The following table shows the cables necessary for connection of

the various devices in a typical system.

The cables must be suitable for the type of installation; for example,

we recommend a cable type H03VV-F for installation indoors or

H05RN-F/H07RN-F if installed outdoors.

Loading...

Loading...