EN

9

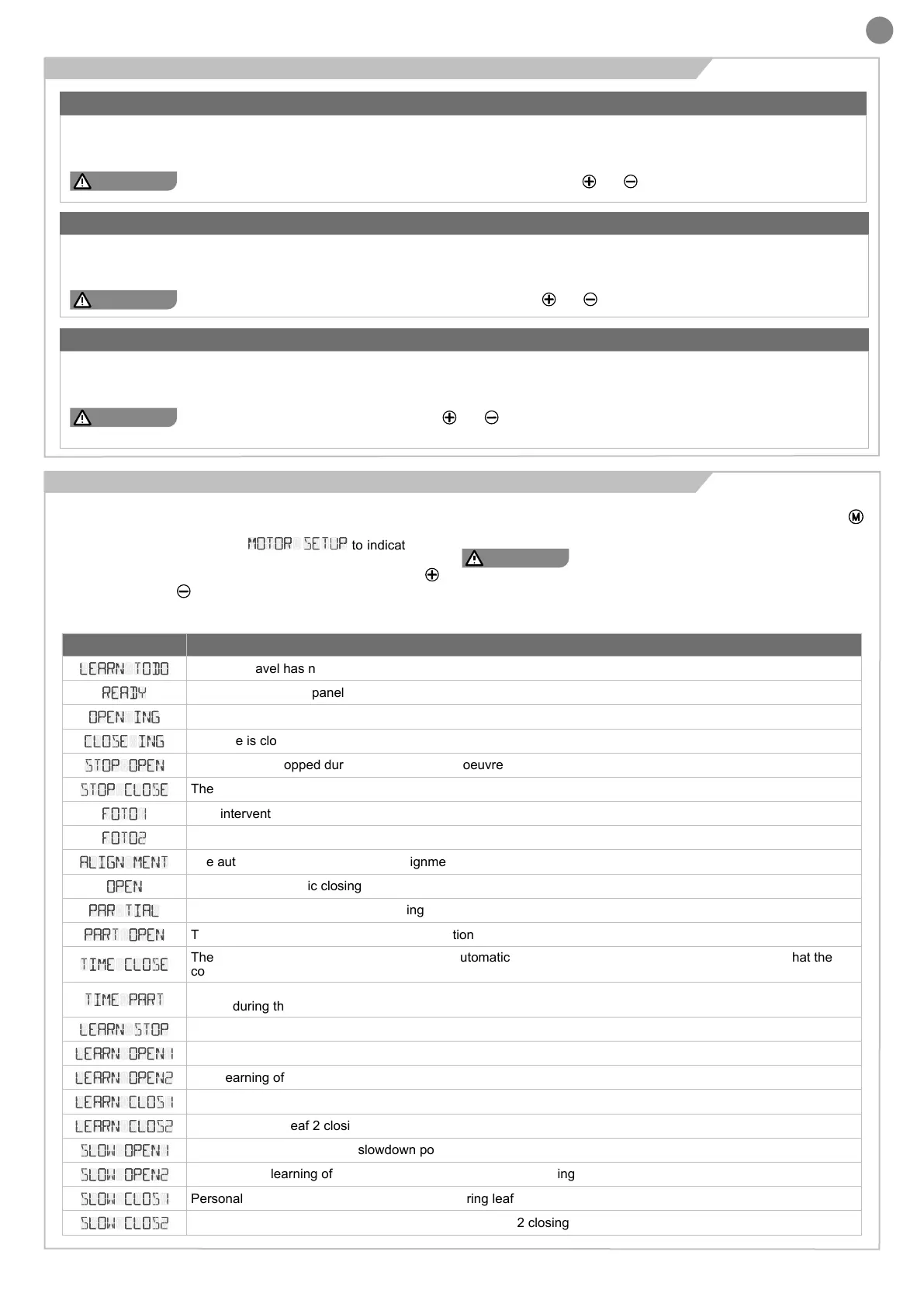

4.2 - Disabling the safety devices

EDGE

The control unit provides (default setting) for the installation of a safety edge connected to the EDGE/EDGE inputs; in the event of a missing or

incorrect connection, the operation of the automation is inhibited. In a system where a safety edge is not to be installed, its use can be disabled

by setting the EDGE dip-switch to ON.

WARNING !

conrm the safety edge deactivation by pressing and holding the buttons and until the EDGE LED stops ashing.

PHOTO 2

The control unit provides (default setting) for the installation of one or more photocells connected to the PH2 input, in the event of a missing

or incorrect connection, the operation of the automation is inhibited. In a system where a PH2 is not to be installed, its use can be disabled by

setting the PH2 dip-switch to ON.

WARNING !

conrm the PH2 deactivation by pressing and holding the buttons and until the PH2 LED stops ashing.

PHOTO 1

The control unit provides (default setting) for the installation of one or more photocells connected to the PH1 input, in the event of a missing or

incorrect connection, the operation of the automation is inhibited. In a system where a PH1 is not to be installed, its use can be disabled by setting

the PH1 dip-switch to ON.

WARNING !

conrm PH1 input deactivation by pressing the and buttons simultaneously and holding them down until the PH1 led

stops ashing.

4.3 - Display during normal operation

When rst switched on, the control unit shows a scrolling text on

the display indicating: board model, rmware version and serial

number and as last information

MOTOR SETUP

to indicate that

it is necessary to select the type of motor to begin conguring the

system. To select the type of motor, scroll the list with the UP

and DOWN-RADIO

buttons;

at the motor concerned, press and hold down the MENU button

until DONE appears on the display.

WARNING !

The ADVANCED PARAMETERS

(paragraph 5.2)

table

shows the correspondence between the motor model and the numbers on

the display.

The following table shows the messages displayed during

normal operation of the automation:

MESSAGE MEANING

LEARN TODO

The door travel has not been learned; perform the auto-learning procedure

READY

Gate closed, control panel restarted

OPEN ING

The gate is opening

CLOSE ING

The gate is closing

STOP OPEN

The gate was stopped during the opening manoeuvre

STOP CLOSE

The gate was stopped during the closing manoeuvre

FOTO1

PH1 intervention (photocell 1)

FOTO2

PH2 intervention (photocell 2)

ALIGN MENT

The automation is performing the realignment procedure

OPEN

Gate open, automatic closing timer not active

PAR TIAL

The gate is performing a partial opening

PART OPEN

The gate is stopped in the partially open position

TIME CLOSE

The gate has reached the open position and automatic re-closing is active; the ashing dash indicates that the

countdown is active. During the last ten seconds, the seconds remaining until reclosing are indicated

TIME PART

The gate has been opened with the PAR command and the automatic re-closing timer from partial opening is

active; during the last ten seconds, the seconds remaining until re-closing are indicated

LEARN STOP

Auto-learning procedure blocked due to safety intervention or intentional stop

LEARN OPEN1

Auto-learning of leaf 1 opening travel

LEARN OPEN2

Auto-learning of leaf 2 opening travel

LEARN CLOS1

Auto-learning of leaf 1 closing travel

LEARN CLOS2

Auto-learning of leaf 2 closing travel

SLOW OPEN1

Personalised learning of the slowdown point during leaf 1 opening

SLOW OPEN2

Personalised learning of the slowdown point during leaf 2 opening

SLOW CLOS1

Personalised learning of the slowdown point during leaf 1 closing

SLOW CLOS2

Personalised learning of the slowdown point during leaf 2 closing

Loading...

Loading...