1-2 Electronic Calibration Modules Reference Guide

General Information

Manual Overview

1-

— A female connector gage has a male interface so it can measure female

devices.

Accuracy of Electronic Calibration versus Mechanical Calibration

As the number of DUT test ports increases, the required number of calibration

measurements also increases. This boosts the probability of bad connections

and bad calibrations when mechanical calibration standards are used rather

than ECal. Also, test port cable repeatability and stability errors are amplified

by the increased number of connections and disconnections. To perform an

SOLT 4-port calibration, a minimum of twelve 1-port standards and three

2-port (thru) standards are measured, requiring a total of eighteen

connections. The same calibration using a 2-port ECal module (N755xA and

N469xD) requires only four connections.

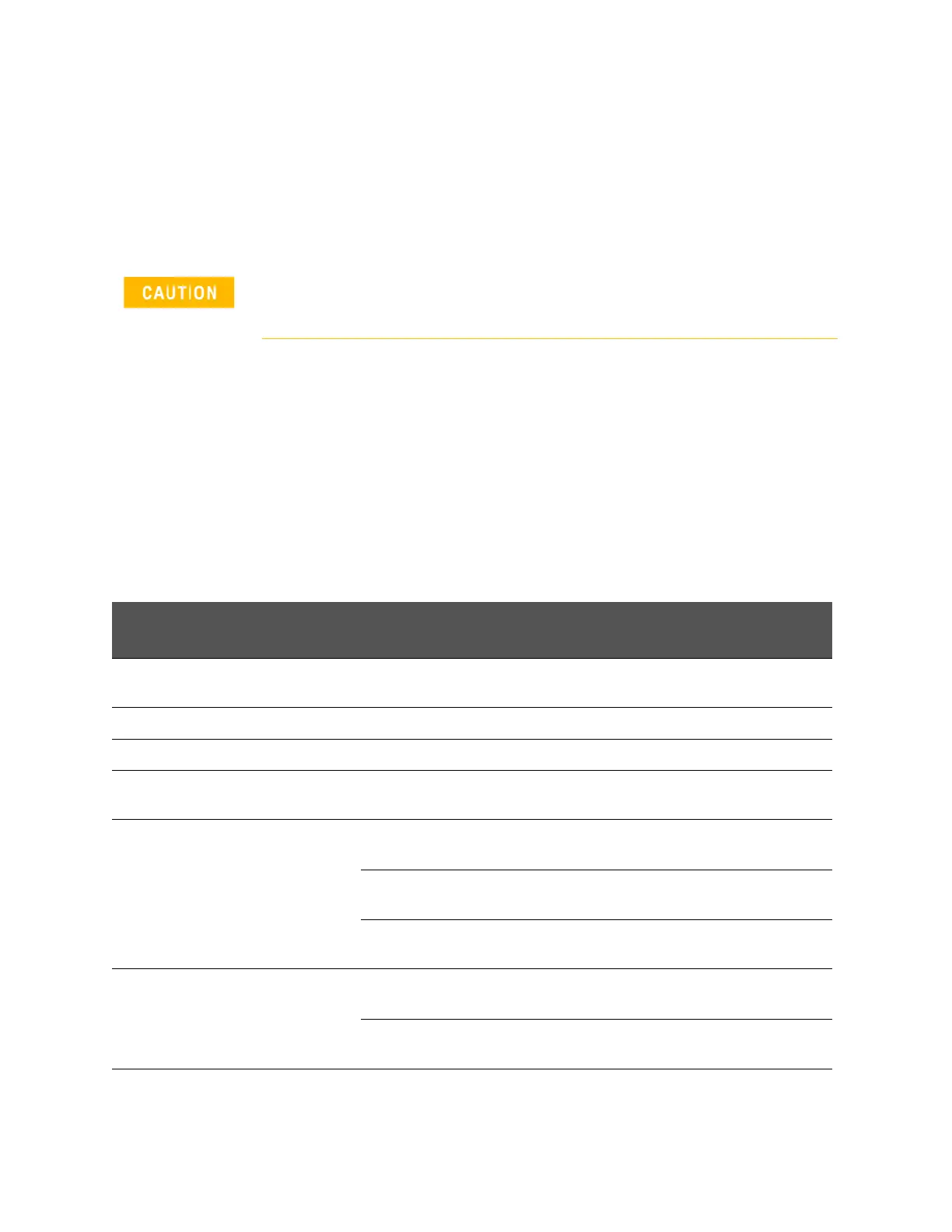

Ignoring connection related errors, the following table compares the accuracy

of ECal versus mechanical calibration in various calibration options.

N755xA ECals can be used for S-parameter measurement calibrations. The

residual measurement uncertainty makes them unsuitable for advanced

applications, such as load pull, noise figure, etcetera.

Mechanical Calibration Type ECal Thru Type Measurement ECal Mechanical

Calibration

1-Port, calibration constant (not

data-based) SOL

NA Reflection ++

1-Port, short, open, sliding load NA Reflection +

1-Port, data-based, expanded NA Reflection +

2-Port TRL All types Reflection

Transmission

++

++

≥2-Port, calibration constant SOL, flush

thru

a

Characterized Reflection

Transmission

++ ++

Internal unknown Reflection

Transmission

++

External flush

a

Reflection

Transmission

++

≥2-Port, calibration constant SOL,

unknown thru

Characterized Reflection

Transmission

++ ++

Internal unknown Reflection

Transmission

++

=

=

Loading...

Loading...