Keystone Boilers and Water Heaters

Page 31

7.2 Pump Connections

Keystone energizes the pump contacts upon a call

for heat. Once the call for heat is satisfied the pump will

remain on for the defined pump overrun time.

NOTE: System and DHW contacts are dry contacts.

Appropriate voltage must be supplied to the System

and DHW pumps for proper operation. Boiler pump

contact (max 7.4 FLA) is fed by 120V (violet wire)

internally from main power feed.

System pump connections are located on terminal

block 5 (TB5) in the control panel (see Figure 25). The

system pump contacts are rated for 120Vac, 7.4 amps.

To use the contacts, power must be supplied on one

terminal with the other terminal wired to the pump or a

relay controlling the pump.

DHW pump connections are located on terminal

block 5 (TB5) in the control panel and are rated for

120Vac, 7.4 amps. To use the contacts, power must be

supplied on one terminal, and the other terminal wired

to the pump or a relay controlling the pump.

7.3 24Vac Transformer with Integral Circuit

Breaker

24Vac is supplied by a transformer mounted

underneath the control panel. All 24Vac power is

supplied through a circuit breaker that is part of the

transformer. The transformer is then connected to

terminal blocks 3 and 4 (TB3 and TB4).

7.4 Hydronic Call for Heat

Connect the call for heat to terminal block 7

(TB7), connections labeled "T-T or interlock" in the

control panel.

7.5 Outdoor Air Temperature Sensor

Connect the outdoor air temperature sensor to

terminal block 7 (TB7), connections labeled Outdoor temp

sensor. The outdoor air temperature sensor is used for

warm weather shutdown and outdoor reset.

NOTE: Setpoint defaults to 120°F without the outdoor

sensor connected.

7.6 Domestic Hot Water Connection

Connect a DHW sensor or aquastat to terminal

block 6 (TB6), connections labeled DHW stat. The

aquastat or sensor will be automatically detected and

initiate the DHW call as needed.

7.7 System Sensor (lead lag/cascading

operation only)

Connect the system sensor to terminal block 6

(TB6), connections labeled system sensor. Can be used

in a well for DHW tank applications with lead/lag.

7.8 External Control Connections

Connect 4-20mA signals from external controls or

building automation systems to terminal block 7 (TB7)

in the control panel. The connections are labeled

"Remote Analog Input". When making the connections

follow the polarity designations shown on the label.

7.9 Optional Field Connections

Terminal block 8 (TB8) in the control panel can be

used for connecting optional components, such as, low

water cutoffs, flow switches, additional high limits and

other field supplied devices that must be interlocked

with the boiler. All safeties or end switches must be

wired in series by removing the supplied jumpers.

7.10 Lead lag/ Cascading Wiring

Connections

Connect each boiler in the cascade system

together by daisy chaining each control from Modbus

port 1 (MB1) of the first boiler to the second and so on.

This can be done using 22awg or thicker shielded

twisted pair wire with drain. Two twisted pairs or three

conductors are needed.

a. To daisy-chain the boilers connect a wire from Modbus

port 1 (MB1) terminal A of the first boiler to Modbus

port 1 (MB1) terminal A of the second boiler.

b. If there are more boilers in the system connect a

wire from Modbus port 1 terminal A of boiler 2 to

Modbus port 1 terminal A of boiler 3.

c. Repeat these steps until all Modbus port1 terminal

A connections are wired.

d. Repeat the above steps for Modbus port 1 terminal

B and C connections to complete the wiring.

e. Connect the drain wire from the twisted pair wire

to ground on one end of the wire only.

7.11 Wiring Diagrams (see Figures 27 and 28)

Caution

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing

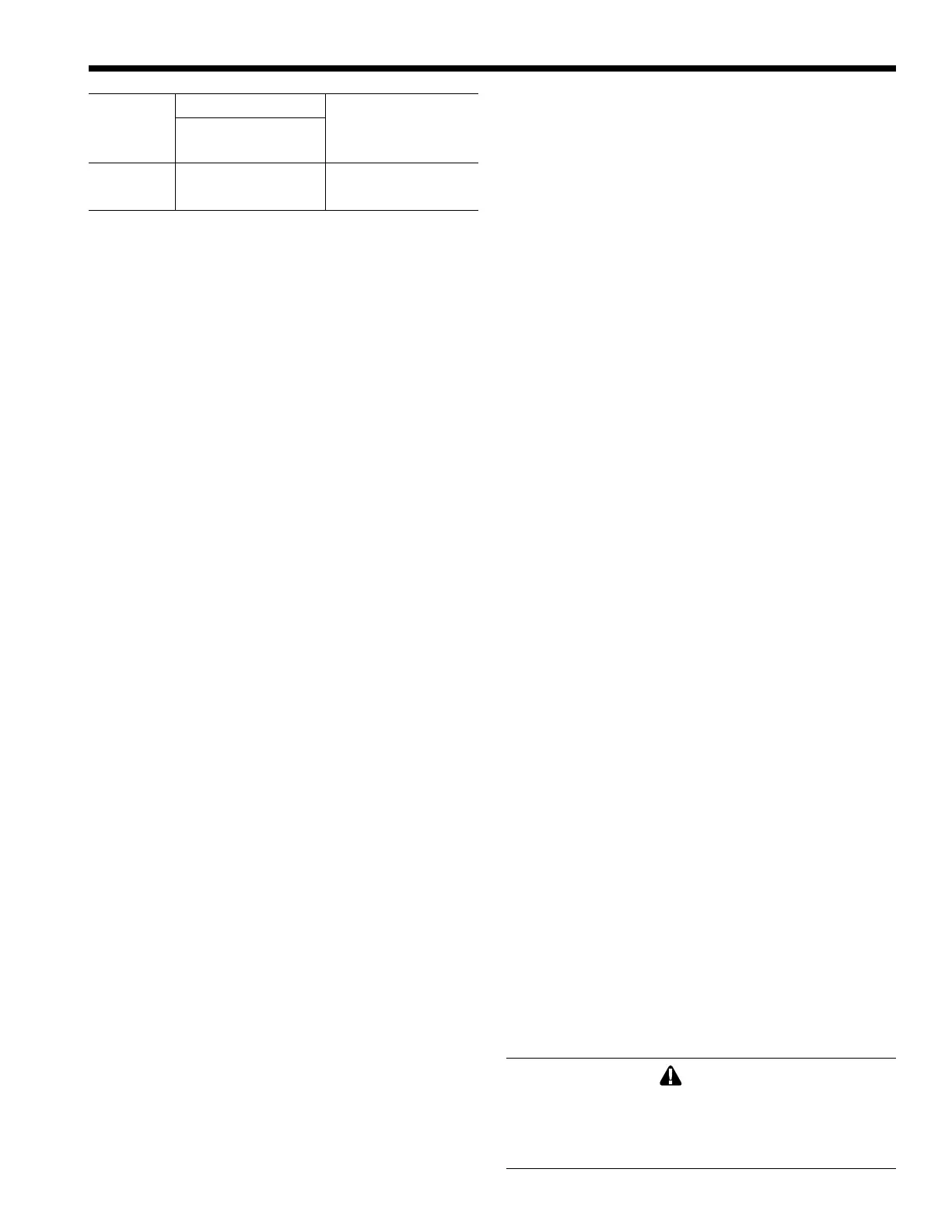

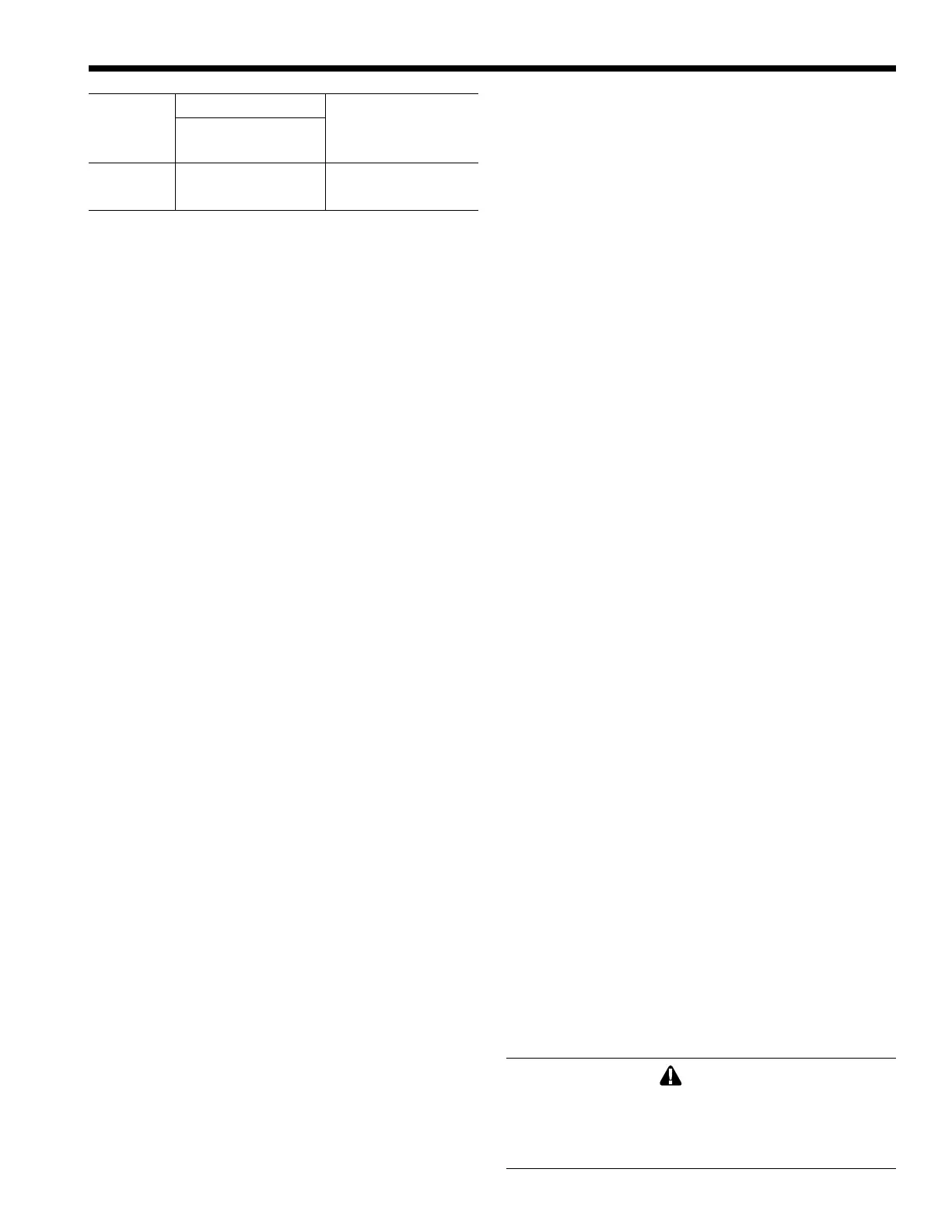

BOILER PUMP CONNECTIONS

PUMP

RATINGS

SELECTION VOLTS PHASE AMPS

(Boiler, System Pump and

DHW Pump Connections)

199–850

120 Single 2*

115V – Maximum 1HP

No Pump or 7.4A max

*

Minimum 15A circuit required

Table 10. Electrical Data.

Loading...

Loading...