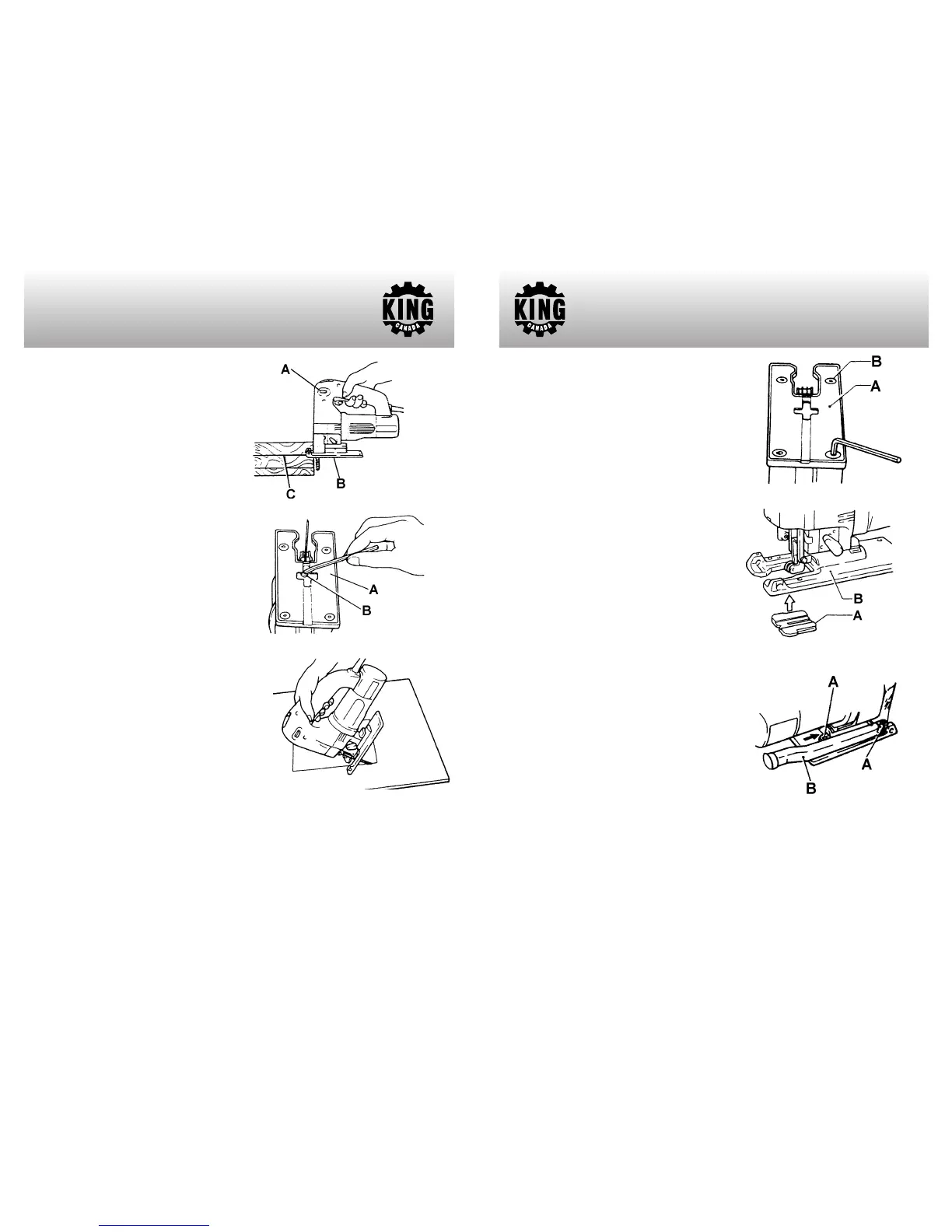

ADJUSTING SPEED SELECTOR DIAL

The machine speed can be adjusted between

500 and 3,000 strokes per minute by turning

the speed selector dial (A) Fig.4. The dial is

marked 1 (lowest speed) to 6 (full speed). In

general, higher speeds will allow you to cut

workpieces faster but the service life of the

blade will be reduced.

CUTTING OPERATION

Rest the base (B) Fig.4 flat on the workpiece

and gently move the machine forward along

the previously marked cutting line (C). When

cutting curves, advance the machine very

slowly.

BEVEL CUTTING

With the base (A) Fig.5 tilted, you can make

bevel cuts at any angle between 0˚ and 45˚

(left or right). Loosen the cap screw (B) on the

bottom of the machine using the hex. key.

Move the base so that the cap screw is

positioned in the center of the cross-shaped

slot in the base. Tilt the base until the desired

bevel angle is obtained. The edge of the

motor housing indicates the bevel angle.

Retighten the cap screw to secure the base.

FLUSH CUTTING

Loosen the cap screw on the bottom of the

machine and move the base all the way back.

Then tighten the bolt to secure the base.

ASSEMBLY & OPERATION

Figure 4

Figure 5

Figure 6

CUTOUTS

Cutouts can be made with either methods A or B.

A) Boring a starting hole: for internal cutouts without a lead-in cut from an edge, pre-drill a

starting hole more than 12mm in diameter. Insert the blade into this hole to start your cut.

B) Plunge cutting: You do not need to bore a starting or make a lead-in cut if you

carefully do as follows: Tilt the machine up on the front edge of the base Fig.6, with the

blade point positioned just above the workpiece surface.

Apply pressure to the machine

so that the front edge of the base will not move when you switch on the machine and

gently lower the back end of the machine slowly. As the blade pierces the workpiece,

slowly lower the base of the machine down onto the workpiece surface. Complete the

cut in the normal manner.

METAL CUTTING

Always use a suitable coolant (cutting oil)

when cutting metal. Failure to do so will cause

a significant blade wear. The underside of the

workpiece can be greased instead of using a

coolant.

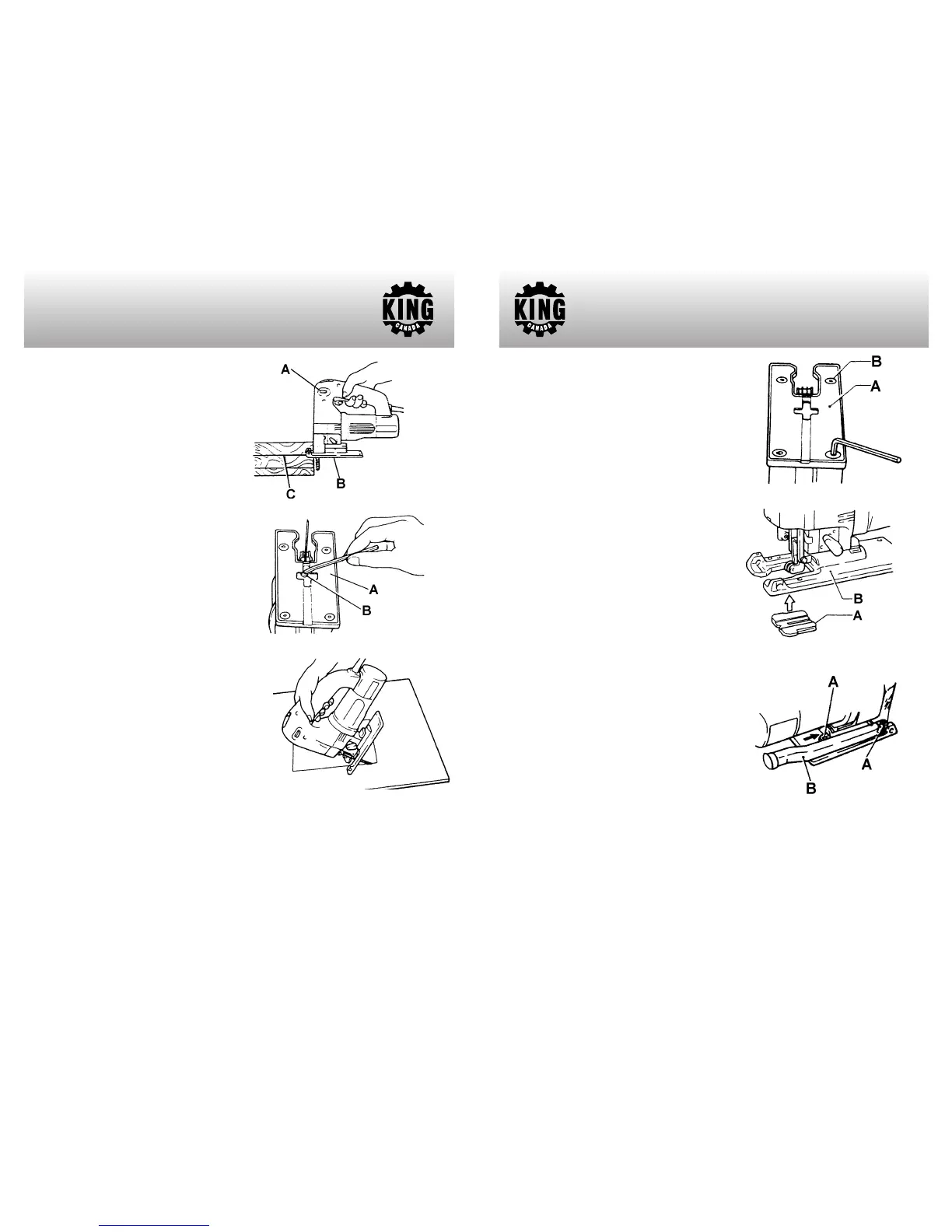

PLASTIC BASE INSERT

Use the plastic base insert (A) Fig.7 when

cutting decorative veneers, plastics, etc. It

protects sensitive surfaces from damage. To

replace the base insert, remove the four

screws (B).

ANTI-SPLINTERING DEVICE

For splinter-free cuts, the anti-splintering

device (A) Fig.8 can be used. Fit into the base

from below as shown.

DUST CHUTE

The supplied dust chute (B) Fig.9 can be

installed on either the right or left side of the

base, depending on practicality. To install the

dust chute, slide the dust chute pins into the

top of the base (A) as shown.

Important note: The front plastic guard must

be removed in order to install the dust chute

to the base (right or left side).

ASSEMBLY & OPERATION

Figure 7

Figure 8

Figure 9

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts

diagram and parts list.

Loading...

Loading...