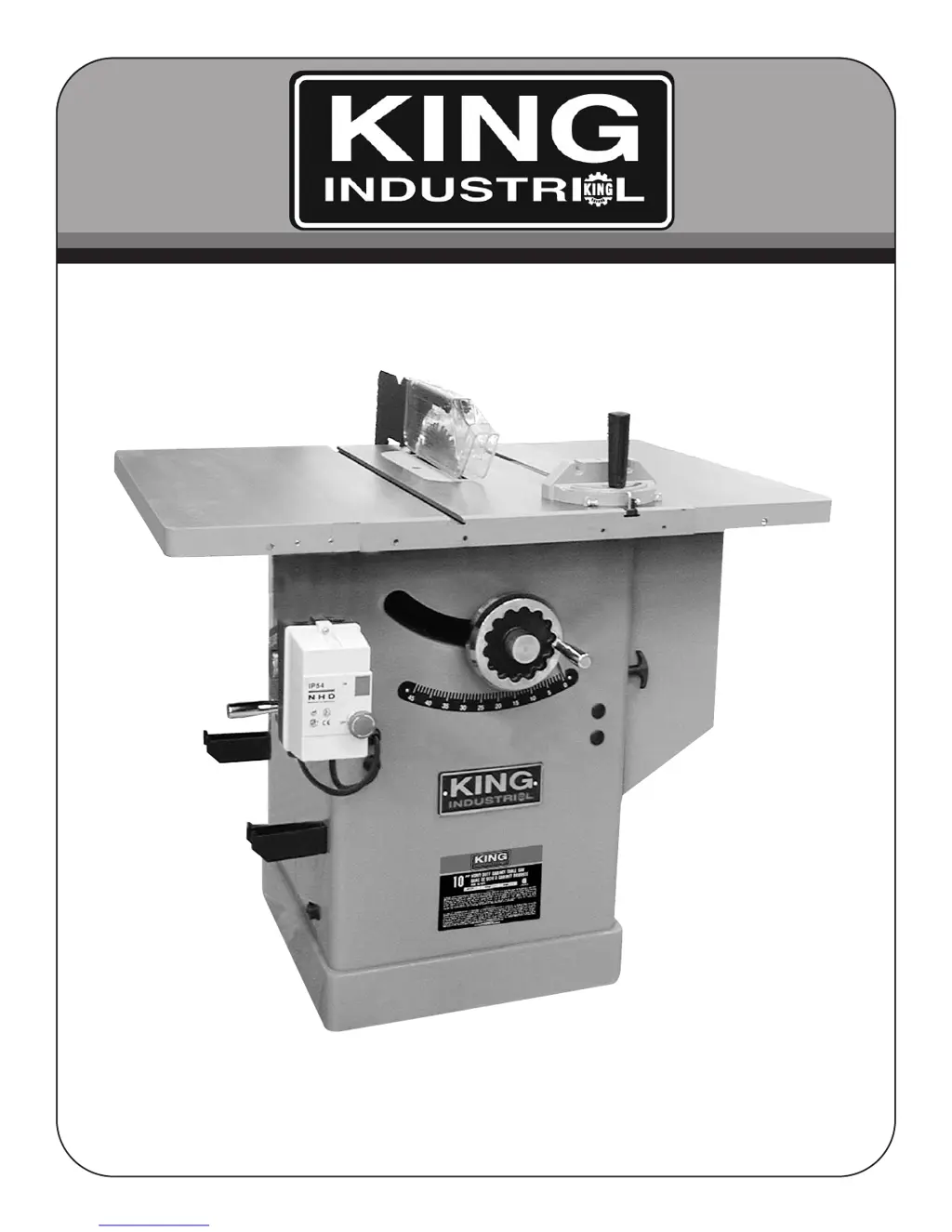

Why my King Industrial Saw will not start?

- JjustincollinsAug 15, 2025

If your King Industrial Saw won't start, there are several potential causes. First, ensure the saw is properly plugged in. If it is, check the fuse or circuit breaker and replace or reset it if necessary. A damaged cord could also be the culprit, in which case you should have it replaced by a certified electrician. Lastly, the overload relay might not be set; try pushing the overload reset button.