IOM/CPHM/DEC19/01 ISSUE DATE:14-12-2019

Page 11 | 48 REVISION NO.1

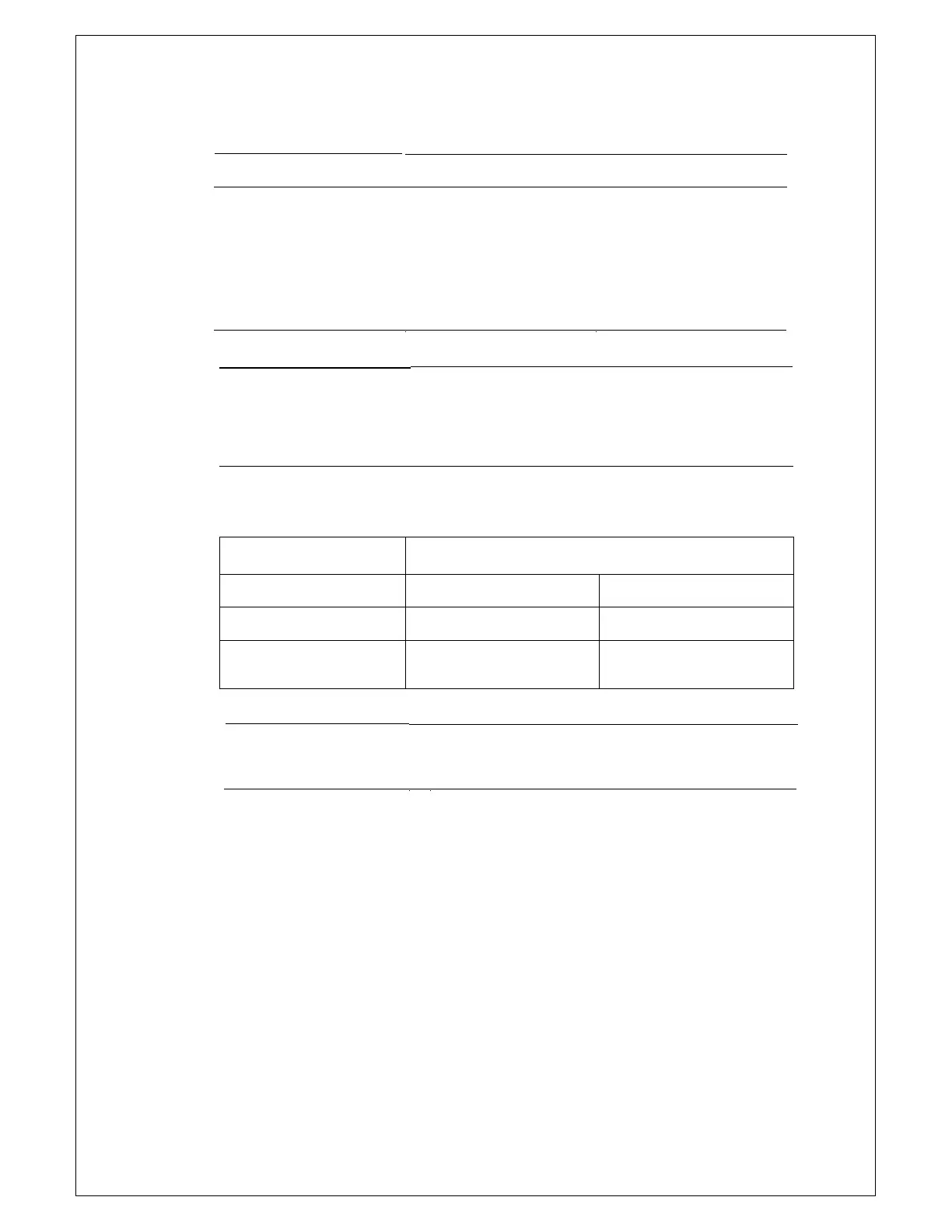

4.3.3 Lubrication of bearings:

Lubrication with grease:

Bearings are grease lubricated. Following are the details of grease grade to be used.

MANUFACTURER SPEED

1500

RPM

3000 RPM

INDIAN OIL

HINDUSTAN

PETROLEUM

SERVOGEM-3

NATRA-3

OR

LITHON-3

SERVOGEM-2

NATRA-2

OR

LITHON-2

CALTEX

STARFAX-3

STARFAX-2

Quantity of

grease:

DRIVING

UNIT QUANTITY APPROX. (GRAMS)

5 6

7 10

9 14

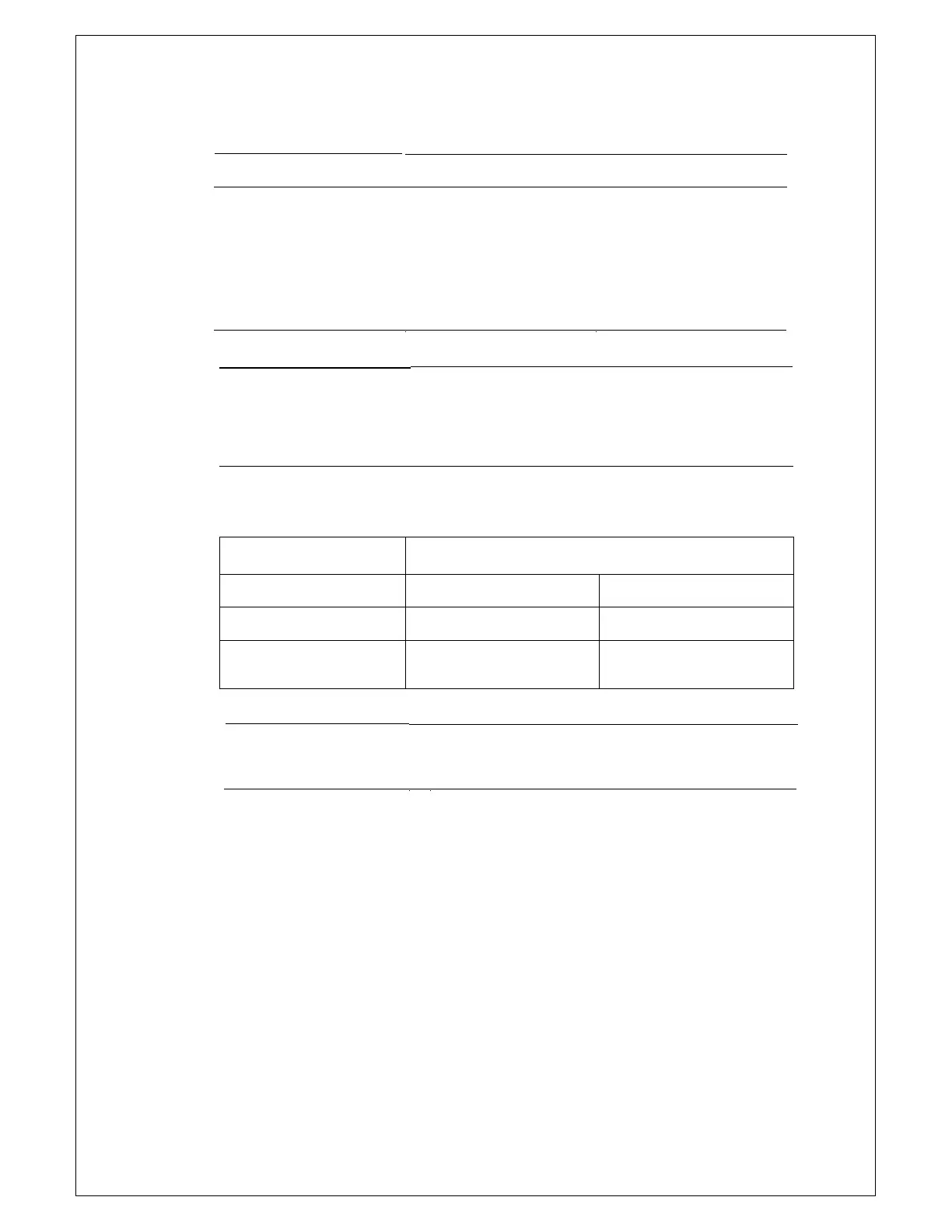

Lubrication with oil:

Bearings are oil lubricated. Following are the details of oil grade to be used.

INDIAN OIL

SERVOSYSTEM-100

SERVOSYSTEM-68

PETROLEUM

Quantity of oil:

DRIVING UNIT QUANTITY APPROX. (LITRES)

11

1.0

13

1.5

4.3.4 Bearing temperature:

A) Maximum allowable temperature of bearings is 35

0

C above ambient.

B) In case of new bearings, renew grease/oil after about 200 hours and then after

twice in a year, if bearing temperature is always below 50

0

C and there is only

small risk of contamination. If the bearing temperature is upto 80

0

C and

if there is danger of contamination, the grease/oil should be renewed after

about every 3 months.

4.4 Specification of stuffing box packing, gaskets and “O” rings:

(Refer Chart No. 4.4(a), 4.4(b) on the next page).

Loading...

Loading...