IOM/CPHM/DEC19/01 ISSUE DATE:14-12-2019

Page 4 | 48 REVISION NO.1

2. INSTALLATION:

2.1 For location, preparing foundation, installation, alignment, piping, general

maintenance, trouble, publication ‘GENERAL INSTRUCTIONS FOR

INSTALLATION, OPERATION AND MAINTENANCE OF KIRLOSKAR

CENTRIFUGAL PUMPS’ which is also printed along with this booklet must be

followed carefully. If the pump is drawing liquid from the vessel under vacuum,

then vacuum equalizing connection piping must be made as per instructions

given in above publication. The external sealing connection to the pump, if

applicable, must be made after installing and before commissioning the pump.

2.2 Mounting and alignment:

A spacer type flexible coupling is recommended to connect pump shaft to the driver.

By using spacer type coupling, the complete rotating unit can be removed from the

volute without removing pump casing or motor and without disconnecting piping

connections. This also avoids any re-alignment of pump and motor after reassembly of

rotating unit. However, other types of coupling can be supplied against request.

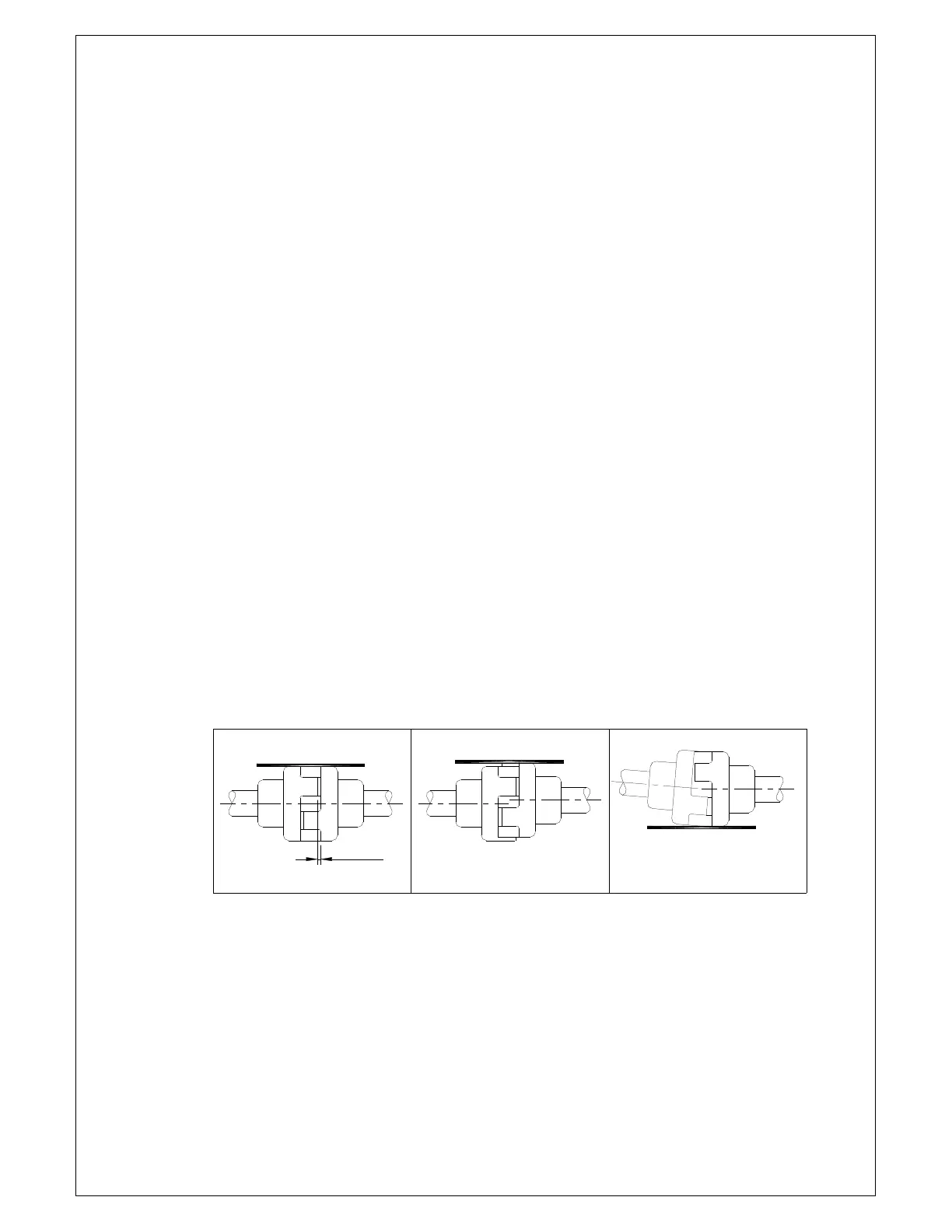

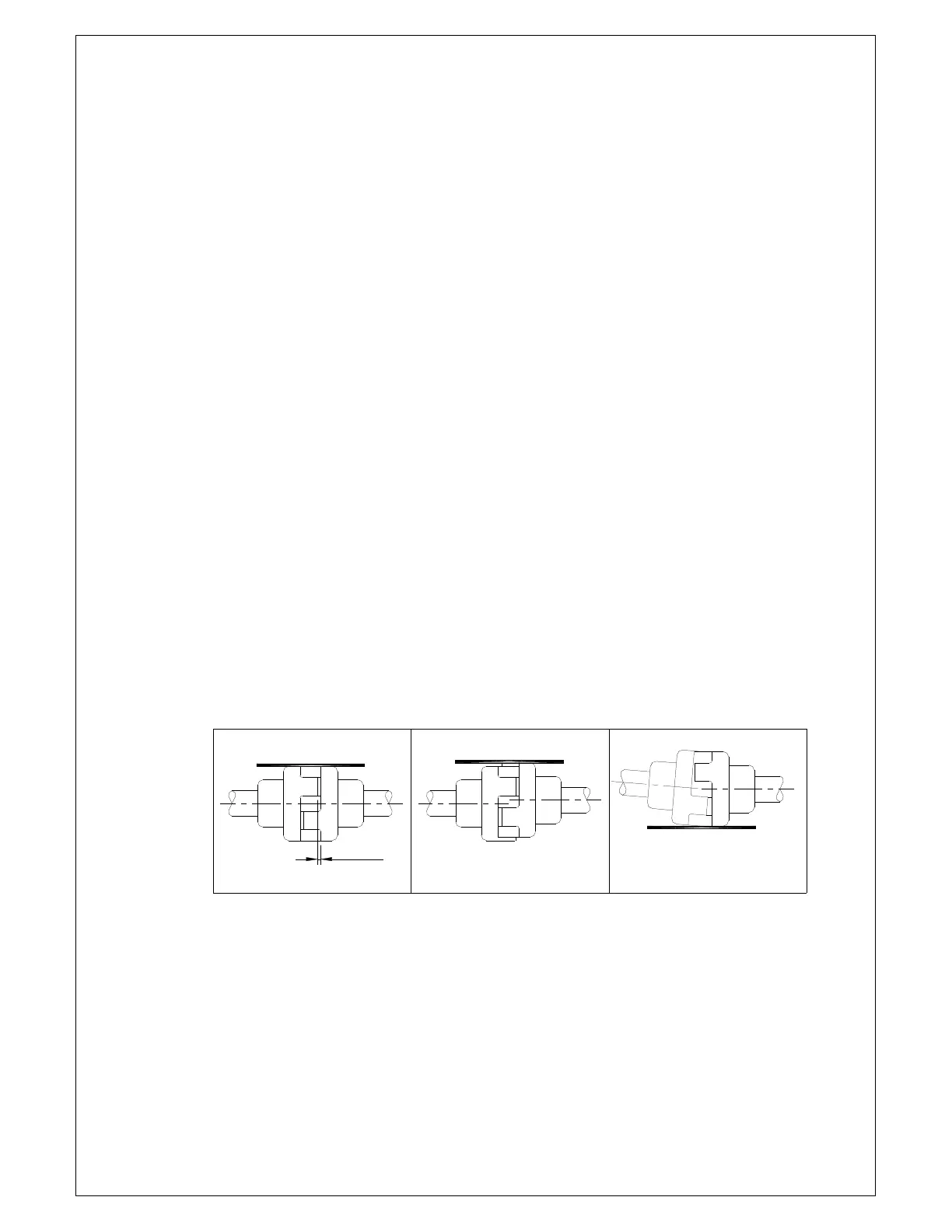

Alignment:

ALWAYS REMEMBER “FLEXIBLE COUPLING IS NOT A UNIVERSAL JOINT”.

Correct alignment is essential for the smooth operation of the pump. There are two

types of mis-alignment between the pump shaft and the drive shaft which are –

i. Angular mis-alignment- Shaft with axis concentric but not parallel.

ii. Parallel mis-alignment- Shaft with axis parallel but not concentric. Mis-

alignment is checked by using straight edge as shown in Fig. 1 at 90

0

apart.

STD

COUPLING

STEEL STRAIGHT

EDGE

STEEL STRAIGHT

EDGE

CORRECT

3mm

INCORRECT

PARALLEL

MISALIGNMENT

STEEL STRAIGHT

EDGE

INCORRECT

ANGULAR

MISALIGNMENT

Fig.

1

Loading...

Loading...