What does warm suction side of H.P. safety mean for KIRLOSKAR KC6?

- PPaul PorterSep 13, 2025

A warm suction side of the H.P. safety indicates a leaking safety valve. Repair or replace the valve.

What does warm suction side of H.P. safety mean for KIRLOSKAR KC6?

A warm suction side of the H.P. safety indicates a leaking safety valve. Repair or replace the valve.

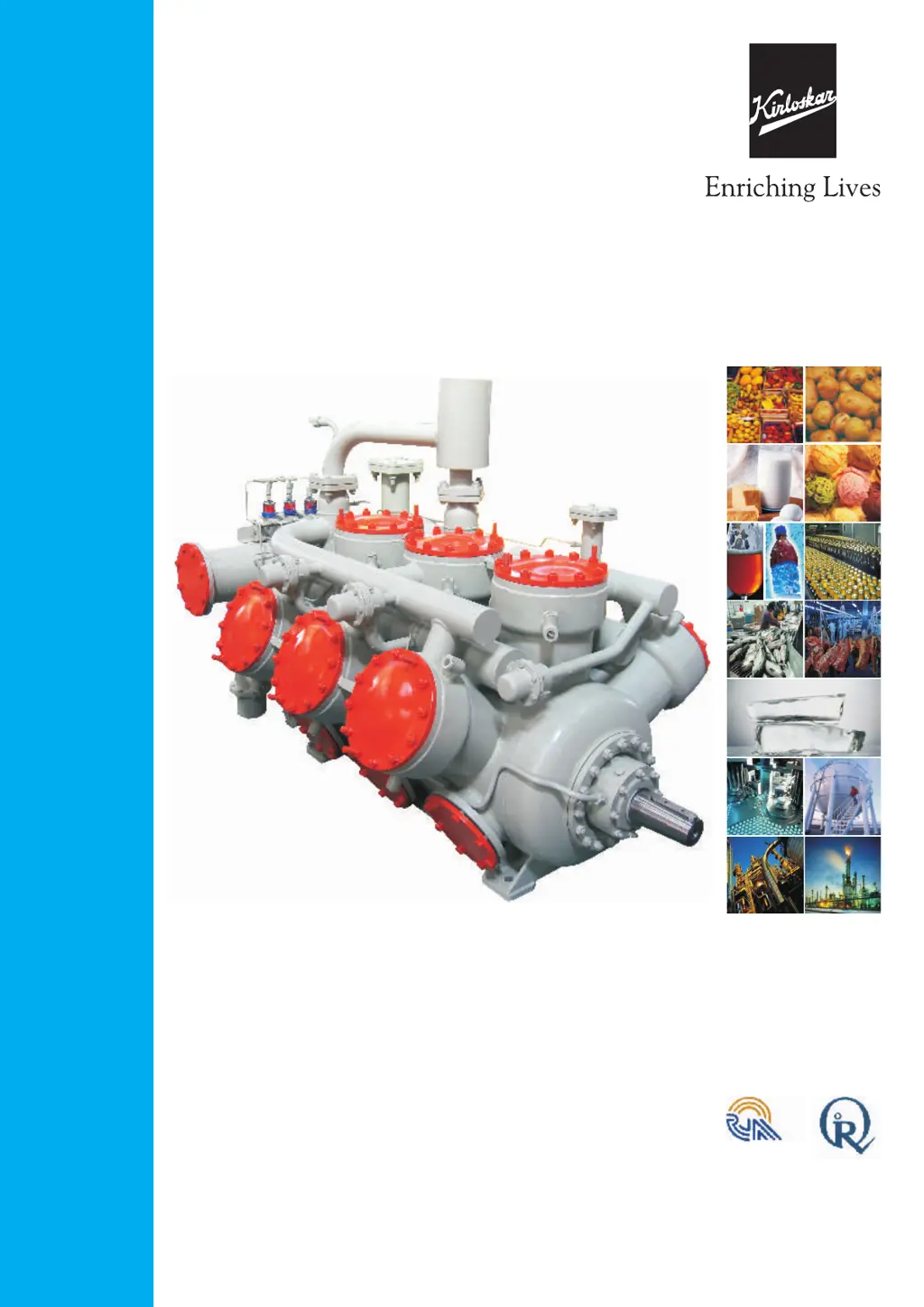

| Brand | KIRLOSKAR |

|---|---|

| Model | KC6 |

| Category | Air Compressor |

| Language | English |

Details on safety valve inspection and function.

Procedure for compressor start-up and normal running.

Risks and consequences of liquid refrigerant entry.

Safety precautions when using ammonia.

Safety precautions when using Freon refrigerant.

Steps before initial compressor run.

Procedure for filling the compressor with oil.

How to adjust the oil pressure regulator.

Procedure for evacuating Freon systems.

Procedure for evacuating Ammonia systems.

Process for charging refrigerant into the system.

Procedure for removing air and moisture from the plant.

Function and settings of pressure switches.

Detailed procedure for starting the compressor.

Checks to perform while compressor is running.

Procedure for stopping the compressor.

Procedure for starting and loading two-stage compressors.

Detailed steps for two-stage compressor operation.

Safety measures for installing parallel compressors.

Maintenance procedures for compressor valves.

Inspection and maintenance of safety valves.

Inspection and replacement of piston rings.

Inspection and maintenance of compressor bearings.

Maintenance and inspection of the shaft seal.

Maintenance and overhaul of the oil pump.

Cleaning and replacement of oil strainers.

Maintenance procedures for suction strainers.

Guidelines for compressor lubrication and oil checks.

Summary table of maintenance tasks by hours.

Troubleshooting issues related to liquid refrigerant.

Key checks to perform during compressor installation.

Loading...

Loading...