What does warm suction side of H.P. safety mean for KIRLOSKAR KC72?

- TTina FosterSep 13, 2025

A warm suction side of the H.P. safety indicates a leaking safety valve. Repair or replace the valve.

What does warm suction side of H.P. safety mean for KIRLOSKAR KC72?

A warm suction side of the H.P. safety indicates a leaking safety valve. Repair or replace the valve.

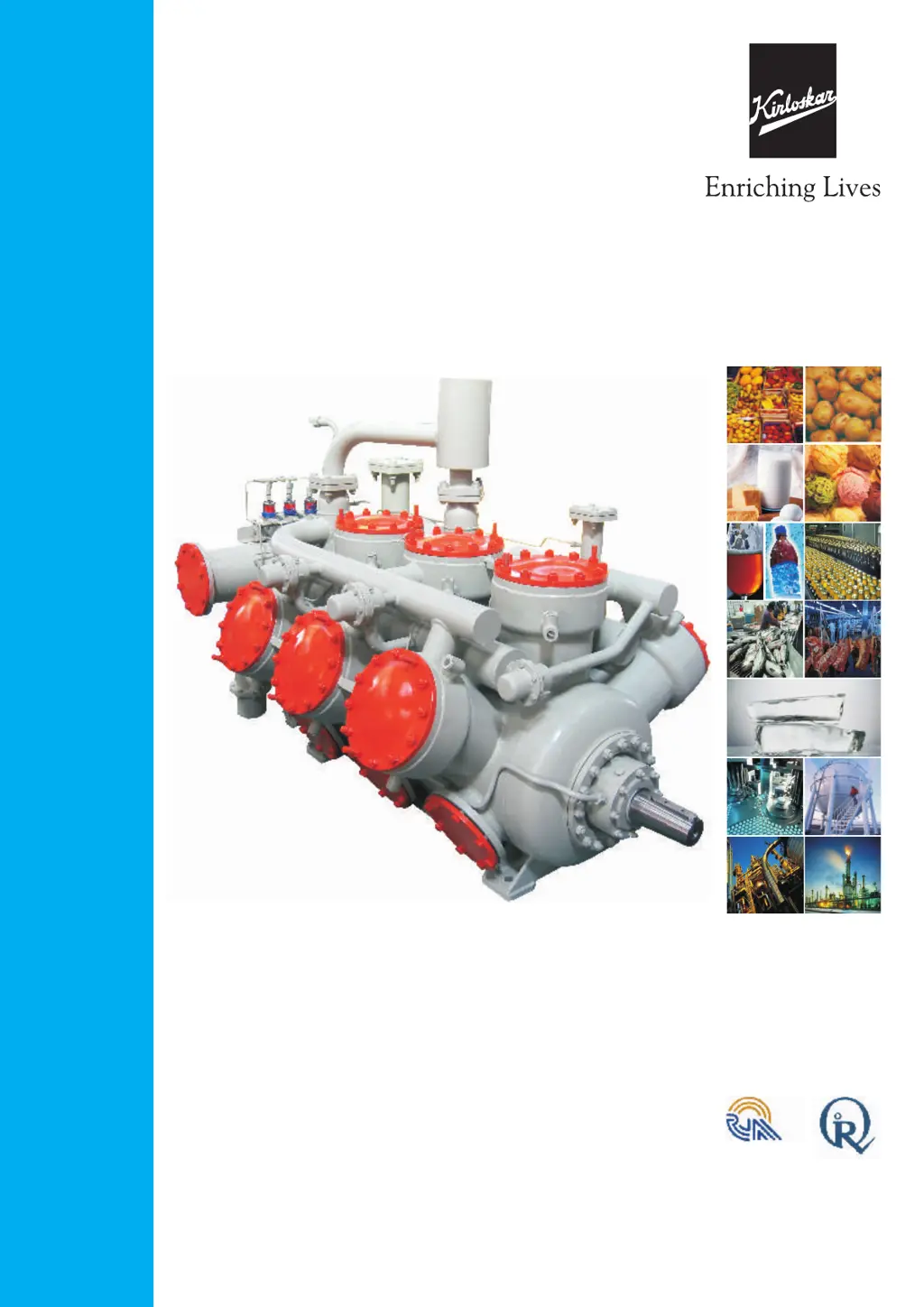

| Model | KC72 |

|---|---|

| Type | Reciprocating Air Compressor |

| Motor Power | 2 HP |

| Power Source | Electric |

| Power Rating | 1.5 kW |

| Maximum Pressure | 175 PSI |

| Noise Level | 82 dB(A) |

| Stages | Two Stage |

| Voltage | 220 V |

Review safety program for hazards from rotating machinery.

Consider hazards from electrical power, hot oil, high pressure, and gases.

Special precautions to prevent power application during maintenance.

Ensure design and operation abide by local safety and environmental laws.

Instructions for correct operation, maintenance, and checks.

Prohibitions during operation and maintenance.

Verify tightness, alignment, oil level, safety cutouts, and gauges.

Pour oil into shaft seal cover and filter housings before starting.

Apply oil and grease to glands before mounting stop valves.

Run compressor on air for five minutes to check oil pressure and loading.

Start on reduced load, then load gradually using CCSV.

Run on direct cylinder, then load capacity steps as temperature drops.

Intermediate pressure must not exceed 4 Kg/cm²g.

Change oil, filters, strainer after initial hours (4, 8, 50, 100 hrs).

Provides technical data for KC2 to KC12 models.

Provides technical data for KC21 to KC102 models.

Describes interchangeable liners, fine boring, and hydraulic lifting mechanism.

Explains forced lubrication, pressure regulator, and filter elements.

Features concentric rings, sinusoidal springs, and identical parts.

Details die cast pistons, rings, and drilled connecting rods.

Describes ground crankshaft, white metal bearings, and dynamic balancing.

Highlights low weight, heat dissipation, and gas-tight construction.

Covers suction valves, oil pump, high pressure supply, and no-load starting.

Details risks of liquid refrigerant and protection device function.

Covers ammonia characteristics, safe storage, and leakage precautions.

Details Freon characteristics, storage, leakage, and ventilation.

Specifies exits, fireproofing, ventilation, accessibility, and noise control.

Steps for installing and filling the compressor with oil.

Details on pouring oil into the strainer and checking oil return.

Procedure to set oil pressure regulator to 1.5 kg/cm² above suction pressure.

Emphasizes checking oil pressure/level and not mixing oils.

Summary of periodic checks and replacements based on operating hours.

Explains function of pressure switches for safety in the control circuit.

Details protection against excessive delivery pressure.

Details protection against minimum suction pressure.

Explains protection against low oil pressure.

Covers the single unit for high and low pressure protection.

Lists common faults, their causes, and suggested remedies.

Continues listing common faults, their causes, and suggested remedies.

Lists common faults, their causes, and suggested remedies.

Addresses issues with solenoid valves and capacity control.

Pinpoints system areas where dirt can enter the compressor.

Covers flushing the system and using strainers with cloth bags.

Outlines pre-start checks, initial run, oil drain, and strainer cleaning.

Details using new oil, checking suitability, and verifying oil pressure.

Emphasizes avoiding hot surfaces, guards, and referring to the manual.

Methods to prevent crankshaft rusting during installation phase.

Procedures for fitting coupling, flywheel, and pulley on the shaft.

Ensures correct base frame, leveling, and proper stud usage.

Loading...

Loading...