Replacing CSC-1001 with CSC-2000/3000 Series Controllers 3 Application Guide, AN0811A Rev. A

© 2012 KMC Controls, Inc. AN0811A Rev. A

KMCControls,Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

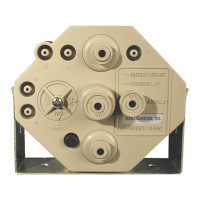

Replacement by CSC-3011

A CSC-3011 “universal” Reset Volume Controller

may also be used to obtain the same functionality of

CSC-1001 Constant Volume Controllers. For constant

volumeapplications, a CSC-3011 should be used in

conjunction with a normally open actuator (connect-

ed to the B port) and an SSS-1000 series ow pickup

(connected between H and L). The T port should be

exhausted. The LO Stat (“low thermostat dierential

pressure”) adjustment knob (center knob) may be set

to maintain the desired constant volume airow. (See

the Constant Volume Application illustration on the

previous page.)

EnsuretheDamperActionSelectionDialisset

properly(NormallyOpenintheseexamples).

VAVapplicationsrequiringahighlimit should be

replaced with a CSC-3011 and an RCC-1008/1108

High Selector Relay. The normally open actuator

should be connected to the B port of the RCC. The

S1 and S2 ports of the RCC should be supplied from

the B ports of the CSC-3011 and a reverse acting

thermostat. The high ow limit can be adjusted using

the LO Stat adjustment knob on the CSC-3011. An

SSS-1000 series ow pickup should be connected be-

tween the H and L ports of the CSC-3011, and the T

port should be exhausted. (See the VAV Application

with a High Flow Limit illustration on the previous

page.)

ForCSC-3011adjustmentandotherinformation,

seetheCSC-3000seriesApplicationGuide.

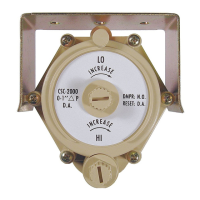

Replacement by CSC-2001/2003

CSC-2000 Series Reset Volume Controllers may be

used to obtain the same functionality of CSC-1001

Constant Volume Controllers. For constantvolume

applications, a CSC-2001/2003 should be used in

conjunction with a normally open actuator (connect-

ed to the B port) and an SSS-1000 series ow pickup

(connected between X and Y). The T port should be

exhausted. The LO adjustment knob (center knob on

the front) may be set to maintain the desired constant

volume airow. (See the Constant Volume Applica-

tion illustration on the previous page.)

VAVapplicationsrequiringahighlimit can be re-

placed with a CSC-2001/2003 and an RCC-1008/1108

High Selector Relay. The normally open actuator

should be connected to the B port of the RCC. The

S1 and S2 ports of the RCC should be supplied from

the B ports of the CSC-2001/2003 and a reverse acting

thermostat. The high ow limit can be adjusted us-

ing the LO adjustment knob on the CSC-2001/2003.

An SSS-1000 series ow pickup should be connected

between the X and Y ports of the CSC-2001/2003, and

the T port should be exhausted. (See the VAV Ap-

plication with a High Flow Limit illustration on the

previous page.)

ForCSC-2001/2003adjustmentandotherinforma-

tion,seetheCSC-2000seriesApplicationGuide.

Loading...

Loading...