239Section 13 Generator Management InformationTP-6953 7/19

Section 13 Generator Management Information

13.1 Generator Management

Purpose

Generator Management is intended to decrease fuel

consumption, environmental emissions, and sound

emissions while improving generator life and

serviceability.

13.2 Generator Management Basic

Function

Generator Management supplies a stop signal to a

generator. If Generator Management fails or is turned

off, the stop signal is removed, resulting in the generator

starting. Most faults relating to Generator Management

will cause it to be disabled, causing the generator to

start.

Generator Management is disabled when the start

signal to the system is removed, and must go through a

stability delay before it will stop generators.

13.2.1 Sequence of Operation

This sequence follows the operation of a normal

paralleling system which uses Generator Management.

When a start signal is applied to any of the generators in

the paralleling system, all the generators that are in auto

andhavenoshutdownfaultswillstart.

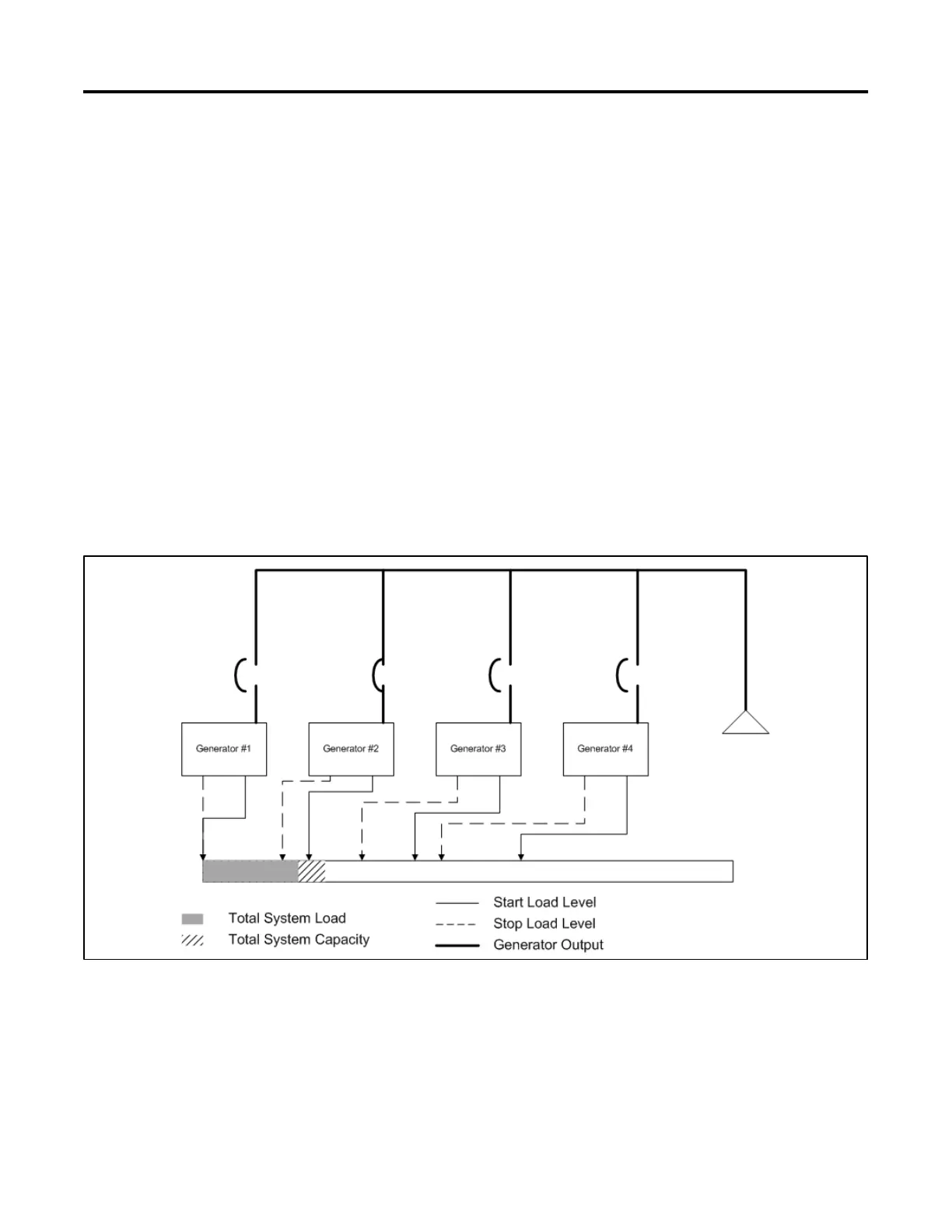

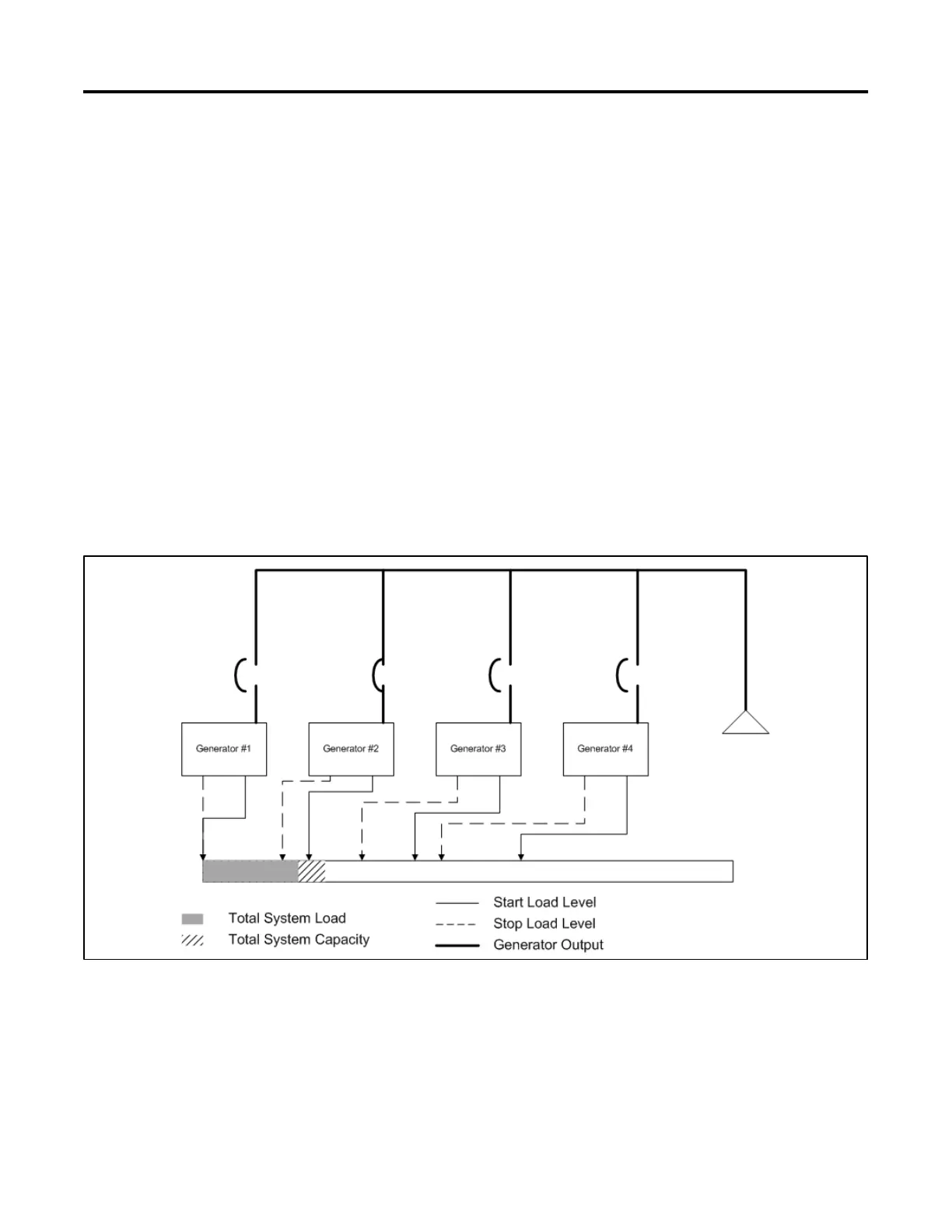

Figure 13-1 illustrates the system after the first

generator has reached rated voltage and frequency and

has closed to the paralleling bus (any of the generators

can be the first to close, d epending on which generator

reaches rated voltage and frequency first). The Total

System Capacity is that of a single generator and the

load is low enough to be supported by a single generator

because non-critical loads have been shed by a Load

Management (also called Load Add/Shed or Load

Control) system (not shown).

Figure 13 -1 A G enerator Energizes the Bus

Loading...

Loading...