TP-6953 7/19 159Section 9 Component Testing and Adjustment

9.7.3 Switch Testing

Before testing switch, disconnect the switch lead(s).

Pressure Switch

Some pressure switches make contact on falling

pressure and some on rising pressure; refer to the

respective drawing for contact style. Connect an

ohmmeter to the switch terminals. Switches with one

terminal require connection to ground on the switch

metal body. Apply the pressure value shown in

Section 1 and observe the ohmmeter before a nd after

values to determine if the switch contacts open and

close per specifications.

Temperature Switch

High water temperature switches make contact on rising

temperature. Low water temperature switches make

contact on falling temperature. Refer to the respective

drawing for contact style. Connect an ohmmeter to the

switch terminals. Switches with one terminal require

connection to ground on the switch metal body. Apply

the temperature value shown in Section 1 and observe

the ohmmeter before and after values to determine if the

switch contacts open and close per specifications.

9.7.4 Sender Testing

Before testing sender, disconnect the sender lead(s).

Pressure Sender

Pressure senders change resistance values as

pressure changes. Connect an ohmmeter to the sender

terminals. Senders with one terminal require

connection to ground on the switch metal body. Apply

pressure values shown in Section 1 and observe the

ohmmeter values to determine if the sender changes

resistance per specifications.

Temperature Sender

Temperature senders change resistance values as

temperature changes. Connect an ohmmeter to the

sender terminals. Senders with one terminal require

connection to ground on the switch metal body. Apply

temperature values shown in Section 1 and observe the

ohmmeter values to determine if the sender changes

resistance per specifications.

9.7.5 Oil Pressu re Sender (OPS)

Testing

Disconnect the oil pressure sender lead 7. See

Figure 9-9. Check the sender resistance with an

ohmmeter. Compare the resistance values when the

generator set is shut down and when it is running at

operating temperature to the values shown in Section 1,

Specifications.

Use a mechanical oil pressure gauge to further verify

correct readings.

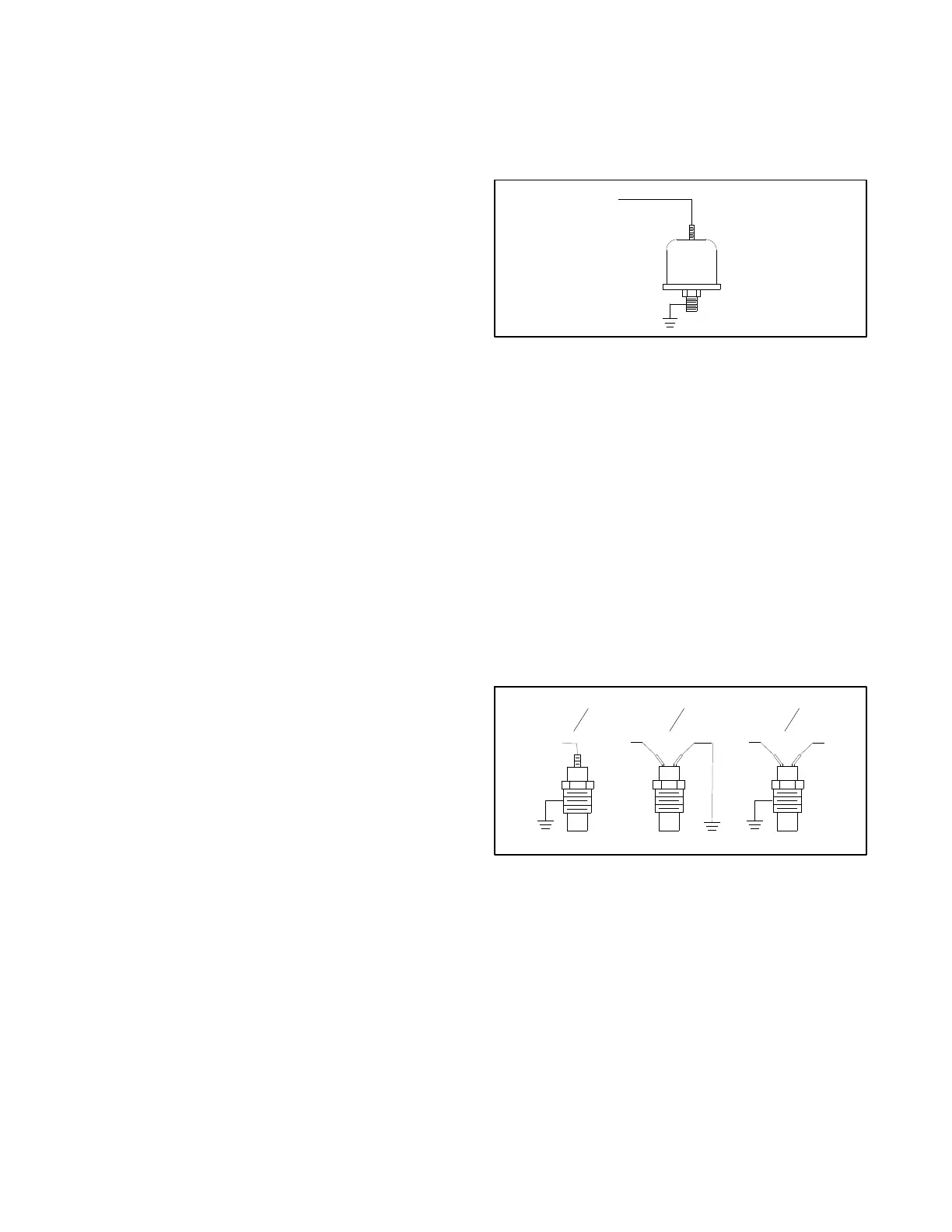

TP-5353-7

Lead 7

Figure 9-9 Oil Pressure Sender, Typical

9.7.6 Coolant Temperature Sender

(CTS) Testing

Note: For 32/40EKOZD and 28/35EFKOZD models,

consult the Engine Service Manual for CTS

testing. See the List of Related Literature found

at the beginning of this manual for the publication

number.

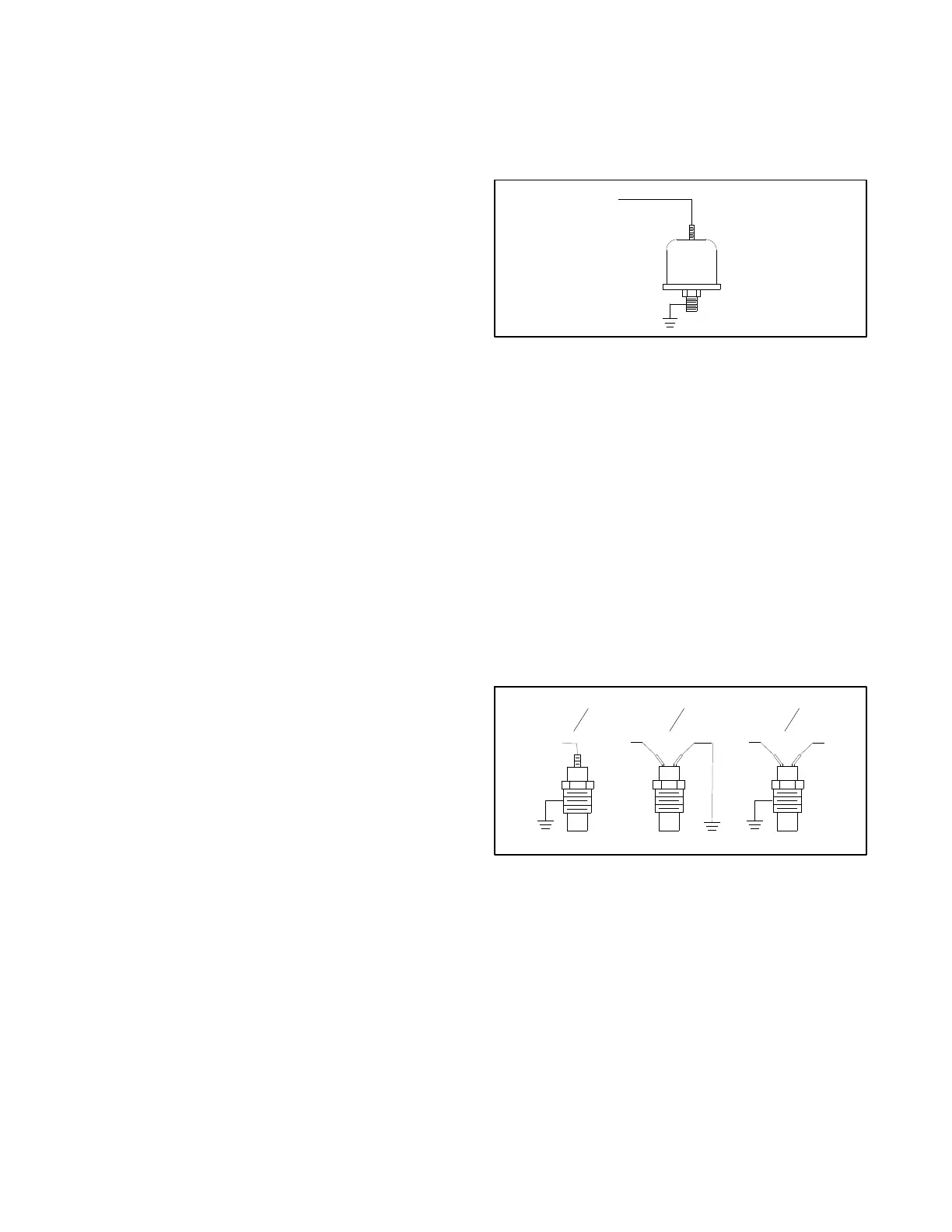

The coolant temperature sender has three

configurations: (1) a single function, single-terminal

type, (2) a single function, two-terminal type, and (3) a

dual function, two -terminal type with temperature

sender and low coolant temperature switch. See

Figure 9-10.

TP-5353-7

Lead 5

55

N

35A

Type 1 Type 2 Type 3

Figure 9-10 Coolant Temperature Sender, Typical

Sender type 3 has lead 5 connected to coolant

temperature sender terminal with a 6-32 screw and

lead 35A connected to the low water coolant

temperatureswitchterminalwithan8-32screw.

Disconnect the coolant temperature sender lead 5 (and

lead N with t ype 2 configurations). Check the sender

resistances with an ohmmeter. Compare the resistance

values when the generator set is shut down and when it

is running at operating temperature to the values listed

in Section 1, Specifications.

Loading...

Loading...