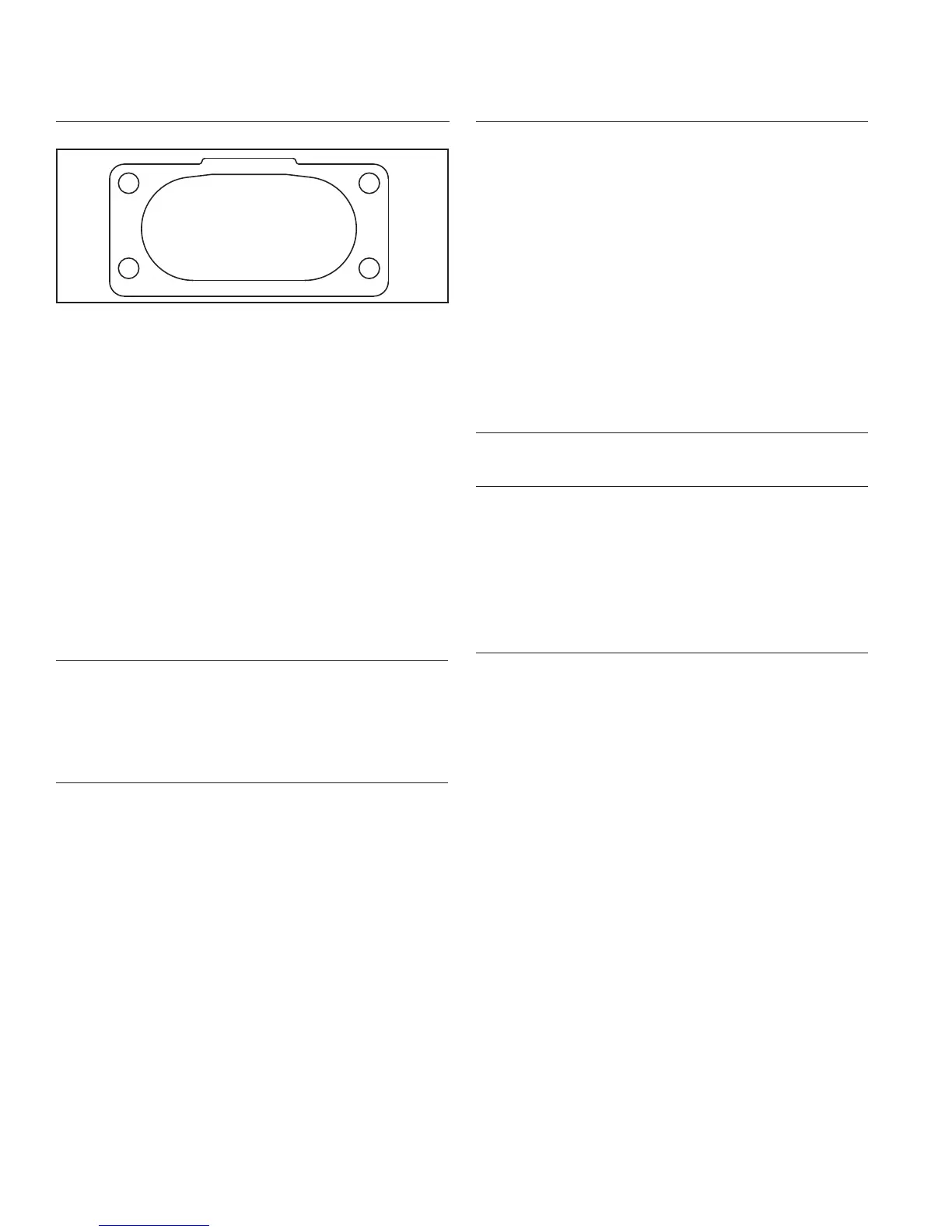

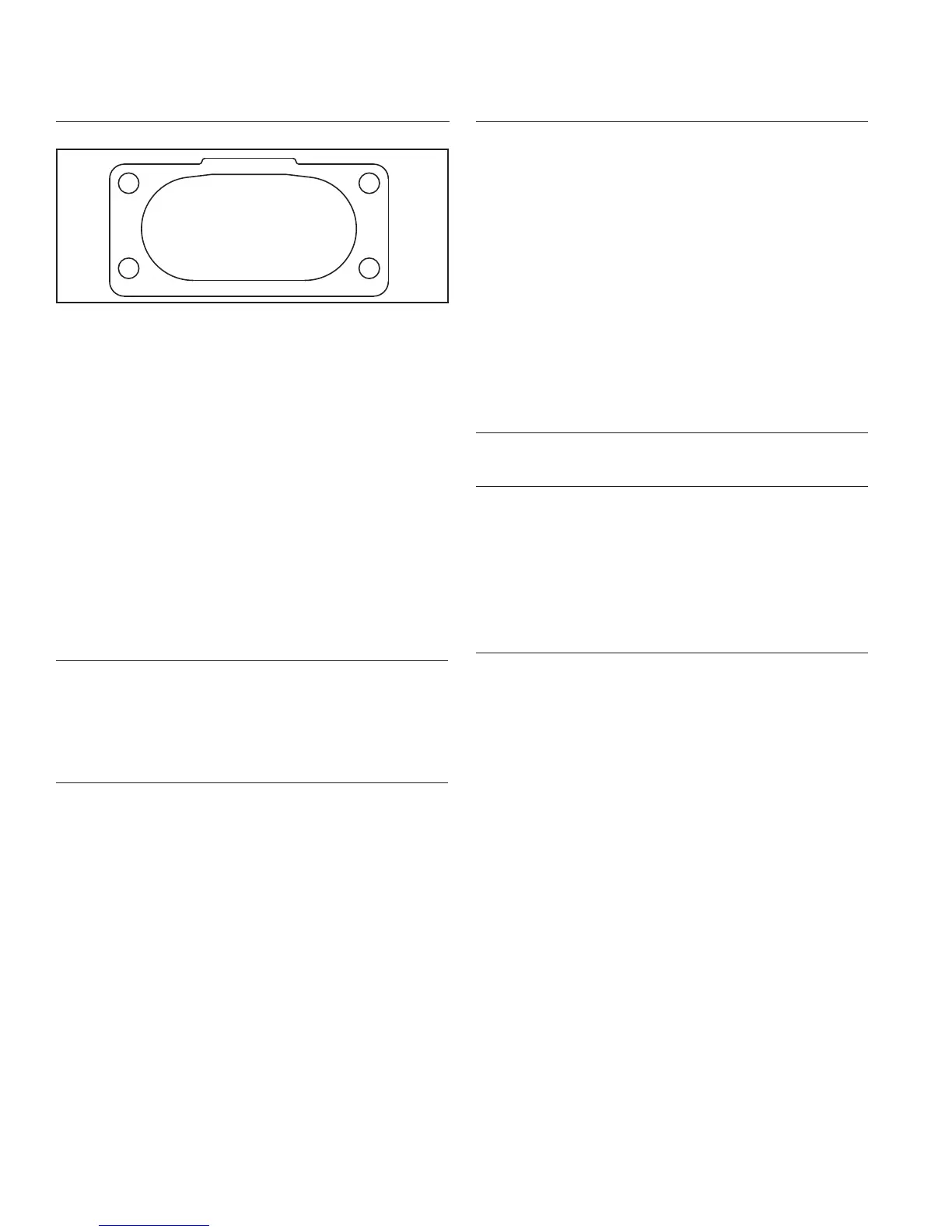

Install Air Cleaner Assembly

Torque Sequence

1, 5

4, 8

3, 7

2, 6

1. Connect breather hose to breather cover and fi tting

on adapter elbow. Route fuel line adjacent to fuel

solenoid, and secure to carburetor inlet with a clamp.

2. Install a new air cleaner gasket. Make sure all holes

align and are open.

3. Align air cleaner mounting bracket (if equipped) with

valve cover mounting holes and start screws.

4. Install air cleaner assembly onto mounting studs.

Secure with hex fl ange nuts. Torque nuts in 2

stages: fi rst to 7.3 N·m (65 in. lb.), then fi nally to

8.2 N·m (73 in. lb.), using sequence shown. Start

two mounting screws into top of intake manifold.

5. Check alignment of bracket and torque valve cover

screws as prescribed in Install Valve Covers. Torque

upper mounting screws into manifold to 9.9 N·m

(88 in. lb.).

6. Connect air cleaner hose to elbow or adapter on

carburetor and secure with a clamp.

Install Muffl er

1. Install port liners (if equipped). Install muffl er and

attaching hardware to muffl er bracket. Torque

screws to 9.9 N·m (88 in. lb.).

2. Install nuts to exhaust studs. Torque nuts to

24.4 N·m (216 in. lb.).

Install Oil Cooler (if equipped)

1. Secure adapter to closure plate with oil fi lter nipple.

Torque oil fi lter nipple to 27 N·m (20 ft. lb.).

2. Install screws and secure oil cooler to blower

housing.

Install Oil Filter and Fill Crankcase with Oil

NOTE: Make sure both oil drain plugs are installed and

torqued to specifi cations to prevent oil leakage.

1. Install oil drain plug(s). Torque plug(s) to 13.6 N·m

(10 ft. lb.). If oil drain valve is used, make sure valve

body is closed and cap is on.

2. Place new fi lter in shallow pan with open end up. Fill

with new oil until oil reaches bottom of threads. Allow

2 minutes for oil to be absorbed by fi lter material.

3. Apply a thin fi lm of clean oil to rubber gasket on oil

fi lter.

4. Refer to instructions on oil fi lter for proper

installation.

5. Fill crankcase with new oil. Level should be at top of

indicator on dipstick.

6. Reinstall oil fi ll cap/dipstick and tighten securely.

Connect Spark Plug Leads

Connect leads to spark plugs.

Prepare Engine for Operation

Engine is now completely reassembled. Before starting

or operating engine, be sure to follow these steps.

1. Make sure all hardware is tightened securely.

2. Make sure oil drain plugs, Oil Sentry

™

pressure

switch, and a new oil fi lter are installed.

3. Adjust carburetor idle speed adjusting screw as

necessary.

Testing Engine

It is recommended engine be operated on a test stand or

bench prior to installation in piece of equipment.

1. Set engine up on a test stand. Install an oil pressure

gauge. Start engine and check to be certain oil

pressure (20 psi or more) is present. Run engine at

idle for 2-3 minutes, then 5-6 minutes more between

idle and midrange. Adjust carburetor mixture settings

as necessary (as available).

2. Adjust idle speed screw and high-speed stop as

necessary. Make sure maximum engine speed does

not exceed 3750 RPM (no load).

Reassembly

68 24 690 34 Rev. DKohlerEngines.com

Loading...

Loading...