Disassembly/Inspection and Service

6162 690 01 Rev. J KohlerEngines.com

Lapping Valves

Reground or new valves must be lapped in, to provide

proper t. Use a hand valve grinder with a suction cup

for nal lapping. Lightly coat valve face with a ne grade

of grinding compound, then rotate valve on its seat with

grinder. Continue grinding until a smooth surface is

obtained on seat and on valve face. Thoroughly clean

cylinder head in soap and hot water to remove all traces

of grinding compound. After drying cylinder head, apply

a light coating of SAE 10 oil to prevent rusting.

Valve Stem Seals

These engines use valve stem seals on intake and

exhaust valves. Always use new seals when valves

are removed from cylinder head. Seals should also be

replaced if deteriorated or damaged in any way. Never

reuse an old seal.

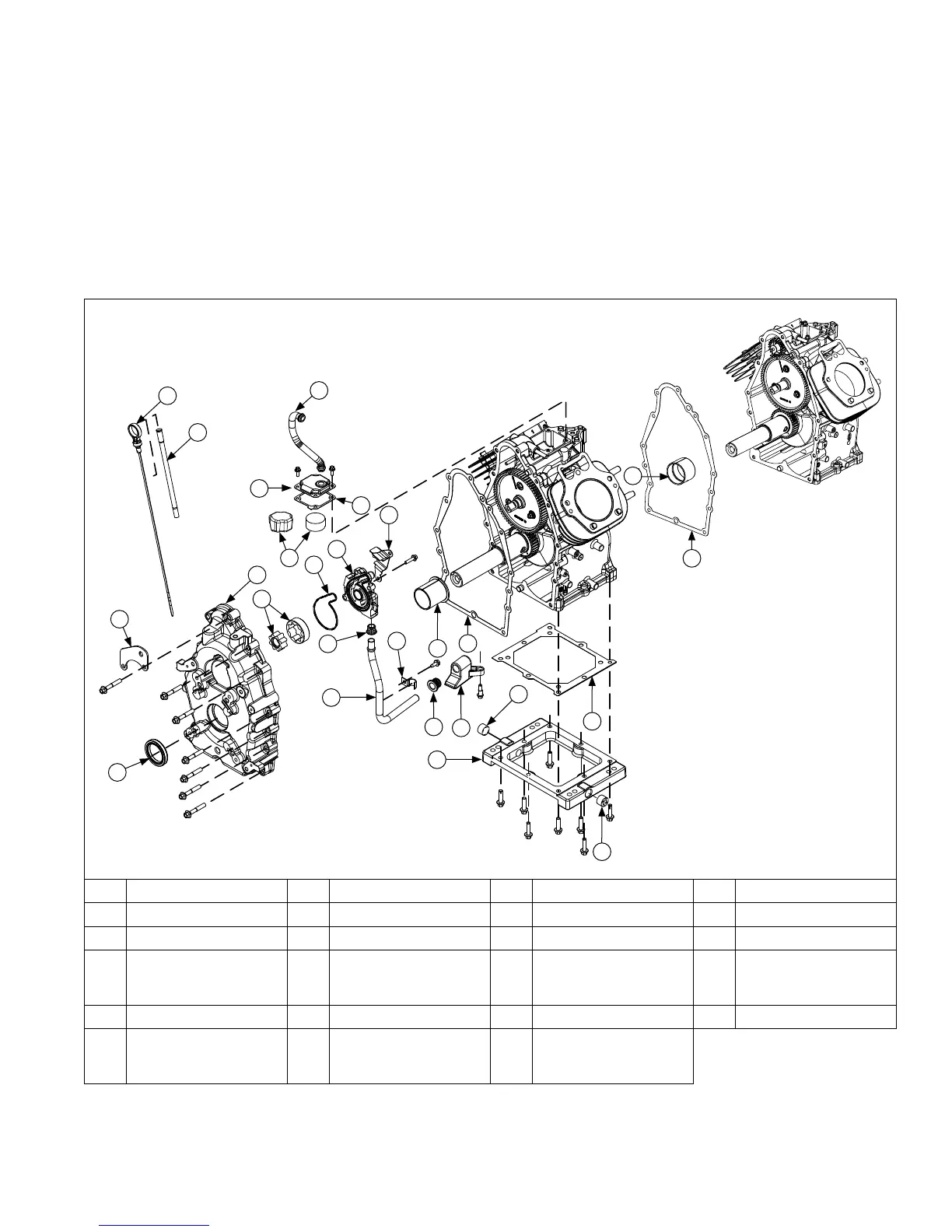

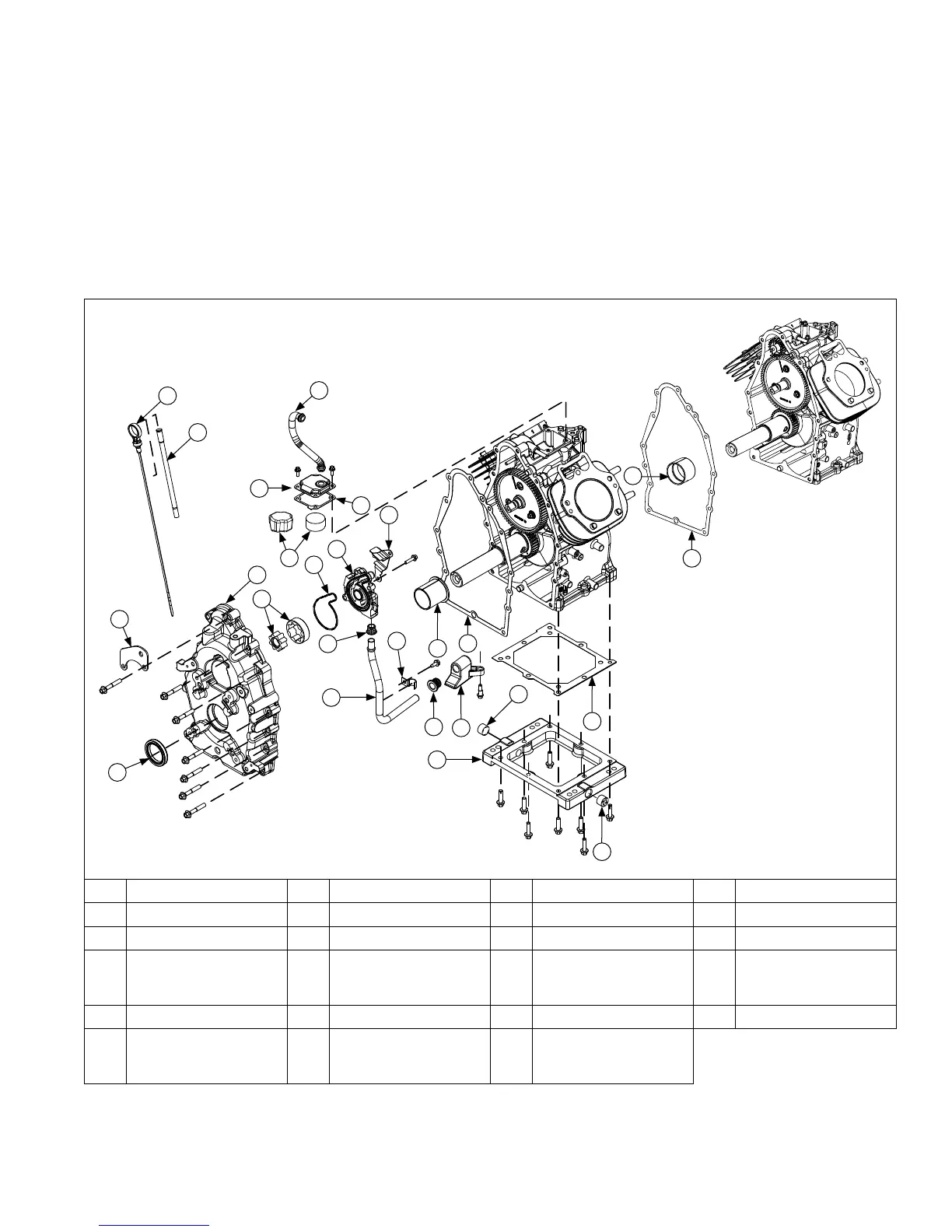

Breather/Closure Plate/Oil Reservoir Components

A

P

O

B

C

Q

R

V

U

S

T

D

F

J

H

K

K

L

M

N

E

H

G

I

N

W

A Closure Plate B Gerotor Gears C Oil Pump O-ring D Oil Pump Housing

E Relief Valve Bafe F Pickup Tube G Clamp H Inlet Seal

I Pickup Screen J Oil Reservoir K Drain Plug L Gasket

M

Crankshaft Thrust

Bearing

(Flange PTO)

N Closure Plate Gasket O Dipstick P Dipstick Tube

Q Breather Assembly R Breather Gasket S Filter T Breather Hose

U Lifting Strap V Oil Seal W

Crankshaft

Non-Thrust Bearing

(PTO)

Loading...

Loading...