Do you have a question about the Kohler Command Pro ECV860 and is the answer not in the manual?

Describes safety precautions before performing maintenance.

Outlines service intervals and tasks for the engine.

Information on obtaining genuine Kohler parts and service.

Details on recommended engine oils based on temperature.

Requirements for gasoline fuel to ensure proper engine operation.

Procedure for storing the engine for extended periods.

Technical measurements of the engine from various viewpoints.

Engine identification numbers and key technical data.

Torque and clearance values for engine components.

Contact information for separate tool vendors.

Specialized tools and aids for engine service.

Overview of common engine issues and their causes.

Problems like starting, running, idling, overheating, and knocking.

Procedures for inspecting and cleaning the engine.

Addresses power loss, oil consumption, and leaks.

Procedure and interpretation for testing crankcase vacuum.

Procedures for testing cylinder compression and leakdown.

Description and maintenance of the air cleaner.

Importance of air cooling and related warnings.

Description of the EFI system, components, and operational modes.

Details on Crankshaft Position, TPS, Temp, and TMAP sensors.

Information on Fuel Injectors and the Fuel Pump Module.

ECU pinout, reset, and TPS learning procedures.

Components, specifications, and linkage for the electronic governor.

Adjustment, diagnostics, and circuit testing for DLA and GCU.

Using blink codes for troubleshooting GCU issues.

Step-by-step troubleshooting for the electronic governor.

Diagram of parts, oil recommendations, and checking oil level.

Procedure for changing engine oil and filter.

Maintenance and testing of oil cooler and pressure switch.

Details, service, inspection, and fouling conditions of spark plugs.

Battery requirements, maintenance, and testing.

Overview of charging system, stator, and rectifier-regulator testing.

Troubleshooting guide for the battery charging system.

Common starting problems and their causes.

Description of starter parts and disassembly procedures.

Inspection and reassembly of armature and brushes.

Procedures for testing the starter solenoid.

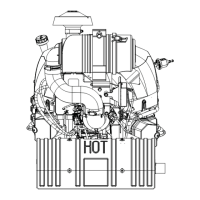

Diagram and list of external engine parts.

Procedures for disconnecting various engine systems.

Procedures for removing key engine components like fuel pump, starter, blower housing, and flywheel.

Procedures for removing and disassembling cylinder heads and valves.

Procedures for servicing crankshaft, connecting rods, and pistons.

Procedures for cylinder bore honing and piston-to-bore clearance measurement.

Procedures for assembling crankcase, oil pan, and internal rotating parts.

Procedures for installing connecting rods, pistons, and camshaft.

Procedures for assembling cylinder heads, valves, and covers.

Procedures for installing baffles, stator, sensors, flywheel, and external components.

| Compression Ratio | 8.5:1 |

|---|---|

| Cooling System | Air-cooled |

| Starting System | Electric |

| Bore | 3.27 in (83 mm) |

| Horsepower | 27 hp |

| Oil Capacity | 2.0 U.S. qt (1.9 L) |

| Engine Type | 4-Cycle, Gasoline, OHV, V-Twin |

| Stroke | 79 mm (3.11 in.) |

| Bore x Stroke | 83 mm x 79 mm (3.27 in. x 3.11 in.) |

Loading...

Loading...