Do you have a question about the Kohler Command PRO EFI ECV940 and is the answer not in the manual?

Explosive Fuel can cause fires and severe burns. Handle gasoline safely to prevent ignition.

Carbon Monoxide can cause severe nausea, fainting, or death. Avoid inhaling exhaust fumes.

Accidental Starts can cause severe injury or death. Disable engine before servicing by disconnecting spark plug lead(s).

High Pressure Fluids can puncture skin and cause severe injury or death. Seek immediate medical attention for injuries.

Electrical Shock can cause injury. Do not touch wires while engine is running.

Rotating Parts can cause severe injury. Keep hands, feet, hair, and clothing away from moving parts.

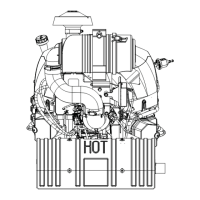

Hot Parts can cause severe burns. Do not touch engine while operating or just after stopping.

The KOHLER Command PRO EFI ECH940 & ECH980, ECV940 & ECV980 Owner's Manual describes a series of electronically fuel-injected (EFI) engines designed for various equipment applications. These engines are characterized by their robust design and advanced fuel management system, which aims to optimize performance and efficiency. The EFI system, monitored by an Electronic Control Unit (ECU), ensures precise fuel delivery, adapting to different operating conditions for consistent power output. A Malfunction Indicator Light (MIL) illuminates if any problems or faults are detected within the EFI system, signaling the need for professional servicing by a Kohler authorized dealer.

The KOHLER Command PRO EFI engines are internal combustion engines primarily designed to power a wide range of outdoor power equipment. Their core function is to convert fuel into mechanical energy, driving the attached machinery. The Electronic Fuel Injection (EFI) system is a key feature, providing electronically controlled fuel management. This system precisely meters fuel into the engine, which can lead to improved fuel economy, easier starting, and better performance across varying altitudes and temperatures compared to carbureted engines. The engine's design incorporates components for oil lubrication, air filtration, and cooling, all essential for its operation and longevity. The oil system ensures critical moving parts are lubricated, while the air cleaner prevents contaminants from entering the engine. The cooling system, including shrouds and fins, dissipates heat generated during operation, preventing overheating.

Operating these engines requires adherence to specific procedures and safety precautions outlined in the manual. Before starting, users must perform a pre-start checklist, including checking oil and fuel levels, inspecting cooling areas for debris, and ensuring all shrouds and guards are securely in place. The starting process involves positioning the throttle control and turning a key switch. The manual provides specific guidance for cold weather starting, recommending appropriate oil viscosity and fresh winter-grade fuel. For stopping, it's advised to remove any external loads and position the throttle control before shutting down the engine. The EFI system contributes to user convenience by potentially offering more reliable starts and consistent performance without manual choke adjustments. However, the manual emphasizes that the governor setting should not be tampered with, as overspeeding is hazardous and voids the warranty. The engine's angle of operation is also a critical usage feature, with warnings against exceeding maximum angles to prevent engine damage from insufficient lubrication.

Regular maintenance is crucial for the longevity and optimal performance of KOHLER Command PRO EFI engines. The manual provides a detailed maintenance schedule, categorizing tasks by weekly, every 25, 100, 150, 200, 300, 500, and 600 hours or annually. Key maintenance tasks include checking the filter minder, servicing/replacing air cleaner components (low-profile and heavy-duty), changing oil and oil filters, and replacing spark plugs. The manual highlights the use of KOHLER PRO 10W-50 Synthetic Oil and KOHLER PRO Extended Life Oil Filter for extended oil change intervals (300 hours), while alternative oils and filters require more frequent changes.

Oil level checks are performed with the engine cool, ensuring the level is at the top of the indicator on the dipstick. Oil and filter changes are recommended when the engine is warm, involving draining old oil, replacing the filter, and refilling with new oil. The manual provides specific torque values for the drain plug and instructions for priming new oil filters. Air cleaner maintenance varies by type (low-profile or heavy-duty), involving cleaning or replacing elements and precleaners. For the EFI system, the fuel filter is a unique component that requires periodic replacement. Spark plug maintenance includes checking and setting the gap, and torquing them to specification. The manual also details how to clean the oil cooler fins and ensure proper air cooling by cleaning screens and external surfaces of the engine. It strongly recommends using a Kohler authorized dealer for major maintenance, service, and parts, especially for emission control devices and systems, to ensure warranty compliance and proper functioning. The manual also includes instructions for storage, such as adding fuel treatment and preparing the engine for extended periods of inactivity.

| Fuel System | Electronic Fuel Injection (EFI) |

|---|---|

| Lubrication | Full pressure lubrication with full-flow filter |

| Cooling System | Air-cooled |

| Governor Type | Mechanical |

| Starter | Electric |

| Spark Plug Gap | 0.030 in. (0.76 mm) |

| Displacement | 999 cc |

| Bore | 90 mm |

| Oil Capacity | 2.0 quarts (1.9 liters) |

| Horsepower | 38 hp |

| Ignition System | Electronic |

| Alternator | 20 amp |

| Fuel Tank Capacity | External Tank Required |

Loading...

Loading...