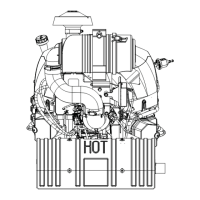

This document is an owner's manual for Kohler Command PRO EFI engines, specifically models ECH940, ECH980, ECV940, and ECV980. It provides essential information for the safe operation, maintenance, and troubleshooting of these engines.

Function Description:

The Kohler Command PRO EFI engines are internal combustion engines designed for various equipment applications. The "EFI" designation indicates Electronic Fuel Injection, a system that electronically controls fuel delivery for improved efficiency and performance. The manual emphasizes the importance of reading all safety precautions and instructions before operation and refers users to the operating instructions of the equipment powered by these engines. It also highlights the need to stop and level the engine before any maintenance or service.

Important Technical Specifications:

The manual includes a "Engine Specifications" table detailing key parameters for the ECH940, ECH980, ECV940, and ECV980 models:

- Bore: 3.54 inches (90 mm)

- Stroke: 3.1 inches (78.5 mm)

- Displacement: 61 cubic inches (999 cc)

- Oil Capacity (Refill): 2 U.S. quarts (1.9 L)

- Spark Plug Gap: 0.03 inches (0.76 mm)

- Maximum Angle of Operation (@ full oil level): 25° (Exceeding this angle may cause engine damage from insufficient lubrication).

The manual also specifies fuel requirements: clean, fresh, unleaded gasoline with an octane rating of 87 (R+M)/2 or higher (Research Octane Number (RON) 90 minimum). Gasoline up to 10% ethyl alcohol and unleaded gasoline blend with max 15% MTBE by volume are acceptable. E15, E20, and E85 fuels are explicitly NOT approved, and their use is not warrantable. High-pressure fuel lines meeting SAE R12 standard are required for EFI systems.

Usage Features:

- Starting: The manual outlines a pre-start checklist including checking oil and fuel levels, cleaning cooling areas, and ensuring all shrouds and guards are in place. For starting, the throttle control should be midway between slow and fast positions, and the key switch turned to START. Continuous cranking for more than 10 seconds is discouraged, with a 60-second cool-down period recommended between attempts to prevent starter motor burnout. A metallic ticking noise upon start-up is noted as potentially normal, suggesting running the engine for 5-20 minutes to see if it subsides.

- Cold Weather Starting: Recommendations include using proper oil for expected temperatures, disengaging external loads, and using fresh winter-grade fuel for improved volatility.

- Stopping: Users are advised to remove the load by disengaging PTO attachments if possible, position the throttle control between half and full throttle, and then stop the engine. If equipped, the fuel shut-off valve should be closed.

- Angle of Operation: Emphasizes adherence to the maximum angle of operation (25°) to prevent engine damage from insufficient lubrication.

- Engine Speed: Warns against tampering with the governor setting to increase maximum engine speed, as overspeeding is hazardous and voids the warranty.

- Electronic Fuel Injection (EFI) System: This system is electronically controlled and monitored by an Electronic Control Unit (ECU). A Malfunction Indicator Light (MIL) will illuminate if problems are detected, requiring service by a Kohler authorized dealer. High-pressure components within the fuel pump module are not serviceable.

Maintenance Features:

The manual provides a detailed maintenance schedule:

- Weekly: Check filter minder.

- Every 25 Hours or Annually: Service/replace low-profile precleaner.

- Every 100 Hours or Annually: Change oil (oil filter recommended), remove cooling shrouds and clean cooling areas.

- Every 150 Hours: Check heavy-duty air cleaner element, replace low-profile air cleaner element, replace unique EFI fuel filter, check and clean oil cooler fins.

- Every 200 Hours: Change oil filter.

- Every 300 Hours: Replace heavy-duty air cleaner element and check inner element.

- Every 500 Hours or Annually: Replace spark plugs and set gap.

- Every 600 Hours: Replace heavy-duty inner air cleaner element.

- More Frequent Maintenance: Procedures should be performed more frequently under severe, dusty, dirty conditions.

Specific maintenance procedures include:

- Oil Recommendations: Recommends Kohler oils or other high-quality detergent oils (including synthetic) of API service class SJ or higher. Viscosity selection is based on air temperature (e.g., 5W-30, 10W-30, SAE 30, 20W-50).

- Check Oil Level: Instructions for checking oil level with both press-in and thread-on caps, ensuring the engine is cool and the level is at the top of the dipstick indicator.

- Change Oil and Filter: Detailed steps for draining warm oil, cleaning around the filter, replacing the filter (pre-filling with oil), refilling the crankcase, checking for leaks, and proper disposal of used oil and filter.

- Oil Sentry™ (if equipped): Describes a switch designed to prevent starting in low/no oil conditions, noting it may not shut down a running engine before damage occurs.

- Fuel System Components: Mentions that high-pressure components in the fuel pump module are not serviceable and highlights the special EFI fuel filter.

- Spark Plugs: Instructions for cleaning the recess, checking and adjusting the gap, installing, and torquing the plugs.

- Fuse Replacement: Provides a fuse chart for three blade-type automotive fuses (10-amp for 2 Solid Red Wires, 1 Red Wire with Black Stripe, 1 Red Wire with White Stripe; 30-amp for 2 Purple Wires).

- Breather Tube: Emphasizes ensuring both ends are properly connected.

- Oil Cooler: Instructions for cleaning fins with a brush or compressed air, noting it's mounted under the cylinder shroud.

- Air Cleaner: Detailed instructions for servicing both low-profile and heavy-duty air cleaners, including precleaner washing/replacement, paper element replacement, and checking components for wear/damage. Warns against operating with loose or damaged components and against blowing out paper elements with compressed air.

- Air Cooling: Stresses the importance of proper cooling by cleaning screens, cooling fins, and external surfaces, and avoiding spraying water at wiring harnesses.

- Storage: For storage exceeding 2 months, procedures include adding fuel treatment, changing oil, pouring oil into cylinders, disconnecting the battery cable, and storing in a clean, dry place.

Safety Precautions:

The manual prominently features several warnings:

- Explosive Fuel: Danger of fires and severe burns. Do not fill the fuel tank while the engine is hot or running. Store gasoline in approved containers in well-ventilated areas away from sparks or flames. Never use gasoline as a cleaning agent.

- Carbon Monoxide: Danger of severe nausea, fainting, or death from inhaling exhaust fumes. Carbon monoxide is odorless and colorless.

- Accidental Starts: Danger of severe injury or death. Disconnect and ground spark plug lead(s) and disconnect the negative battery cable before servicing.

- High Pressure Fluids: Danger of skin puncture and severe injury/death. Do not work on the fuel system without proper training and safety equipment. Seek immediate medical attention for puncture injuries.

- Rotating Parts: Danger of severe injury. Stay away from moving parts while the engine is in operation. Never operate with covers, shrouds, or guards removed.

- Hot Parts: Danger of severe burns. Do not touch the engine while operating or just after stopping. Never operate with heat shields or guards removed.

- Electrical Shock: Danger of injury. Do not touch wires while the engine is running.

California Proposition 65 Warning:

The manual includes two warnings regarding chemicals in engine exhaust and the product itself, known to the State of California to cause cancer, birth defects, or other reproductive harm.

Troubleshooting:

A troubleshooting table lists common problems (Will Not Start, Hard Starting, Stops Suddenly, Lacks Power, Operates Erratically, Knocks or Pings, Skips or Misfires, Backfires, Overheats, High Fuel Consumption) and possible causes (Improper Fuel, Dirt In Fuel Line, Broken Fusible Link, Dirty Screen, Incorrect Oil Level, Engine Overloaded, Dirty Air Cleaner, Faulty Spark Plug). It advises that major engine components or items requiring special timing/adjustment should be serviced by a Kohler authorized dealer.

Warranty and Service:

The manual states that warranty coverage is outlined in the warranty card and on KohlerEngines.com. It recommends using a Kohler authorized dealer for maintenance, service, and parts, providing contact information (KohlerEngines.com or 1-800-544-2444). It also notes that normal maintenance, replacement, or repair of emission control devices can be performed by any repair establishment, but warranty repairs must be done by an authorized dealer. Compliance with emission regulations requires exhaust system backpressure not to exceed limits found on KohlerEngines.com.

Loading...

Loading...