114

5

4

7

V

8

1

2

3 9

6 10

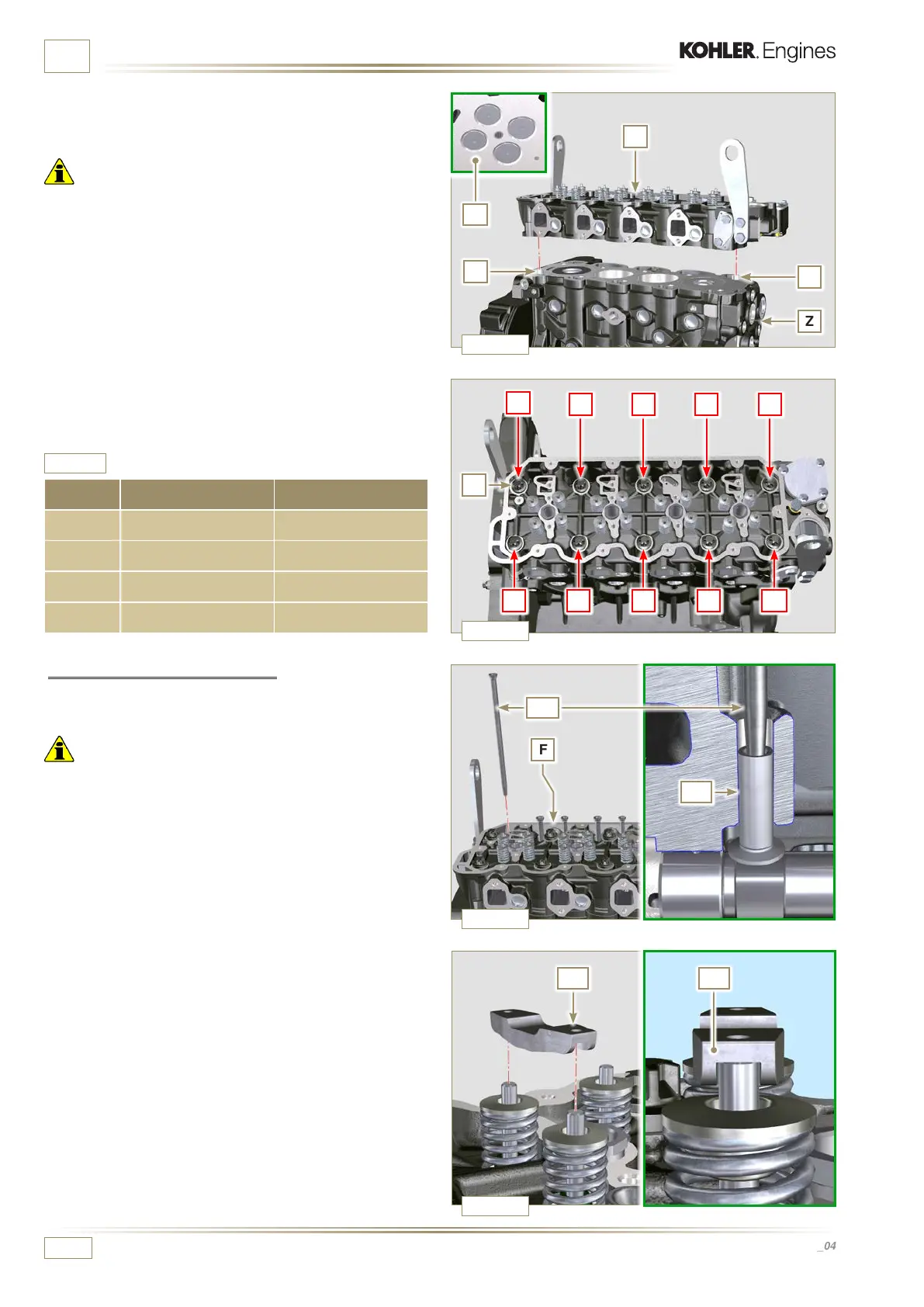

Fig. 9.46

Fig. 9.45

F

W

Z

J

J

Fig. 9.43

Fig. 9.44

AC AC

AB

F

AA

Tab. 9.19

ED0053030410

ASSEMBLY INFORMATION

7 - Check that the surface head W is free from impurities.

8 -

Position the head F on the crankcase Z with reference to

the centering bushings J.

Important

• The fastening bolts V must be replaced every time they are

assembled.

• Failure to adhere to the bolt fixing procedures may

compromise the functionality of the engine, and also may

cause damage to persons and property.

• Tighten capscrews V observing the cycles, tightening, and

subsequent rotation as indicated in Tab. 9.5.

9 -

Apply "Molyslip AS COMPOUND 40" on the threads and

under the head of capscrew V and manually tighten them

until their stop.

10 -

Secure the head F by tightening the screws V strictly

following the sequence indicated in the Fig. 9.44 and the

tightening torque and pauses between cycles indicated in

the Tab. 9.5.

CYCLE TORQUE PAUSE

1 28 Nm 3"

2 30° 3"

3 30° 10"

3 30° ...

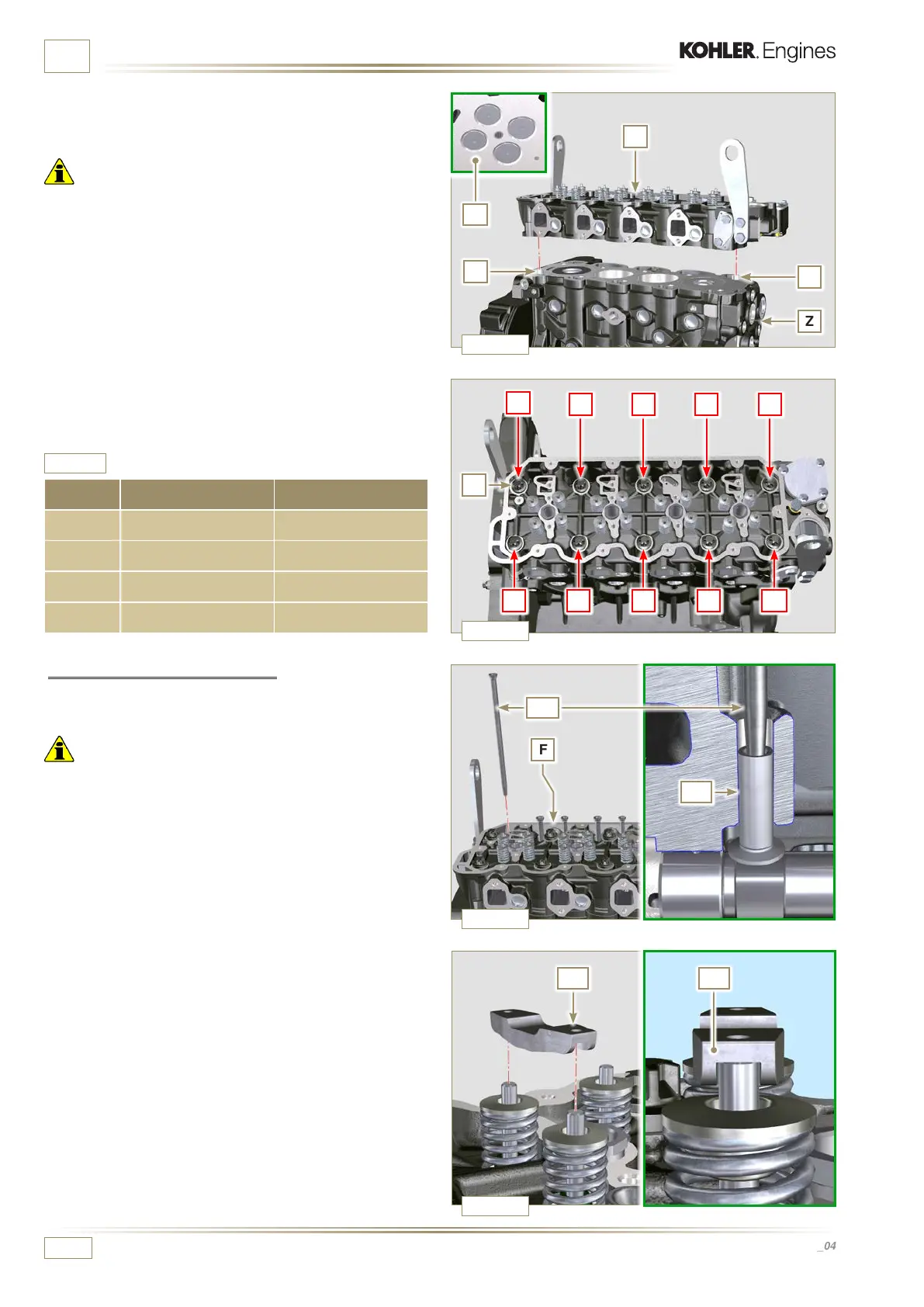

2 - Mount the valve bridge AC on to the pairs of discharge and

suction valves.

9.5.6 Rods and valve bridges

1 - Insert the rocker control rods AA into the niches of the

head F.

Important

• Properly centre the rods AA into the spherical housing of the

camshaft tappets AB.

Loading...

Loading...