134

A

A1

A2

A

D

B B

Fig. 12.4

Fig. 12.5

A C

B

C

Fig. 12.2

Fig. 12.3

ED0053030410

INFORMATION ON ADJUSTMENTS

12.3 Oil steam separator check

1 -

Loosen clamp B and remove hose C from separator A.

2 - Remove rapid fitting D from separator A.

3 - Start the engine at idle speed or without a load and check

if air comes out from unions A1 and A2.

NOTE: If what is described in Point 3 does not occur, proceed

with cleaning or replacing oil separator A and all

connecting hoses. Repeat the operation from point 3.

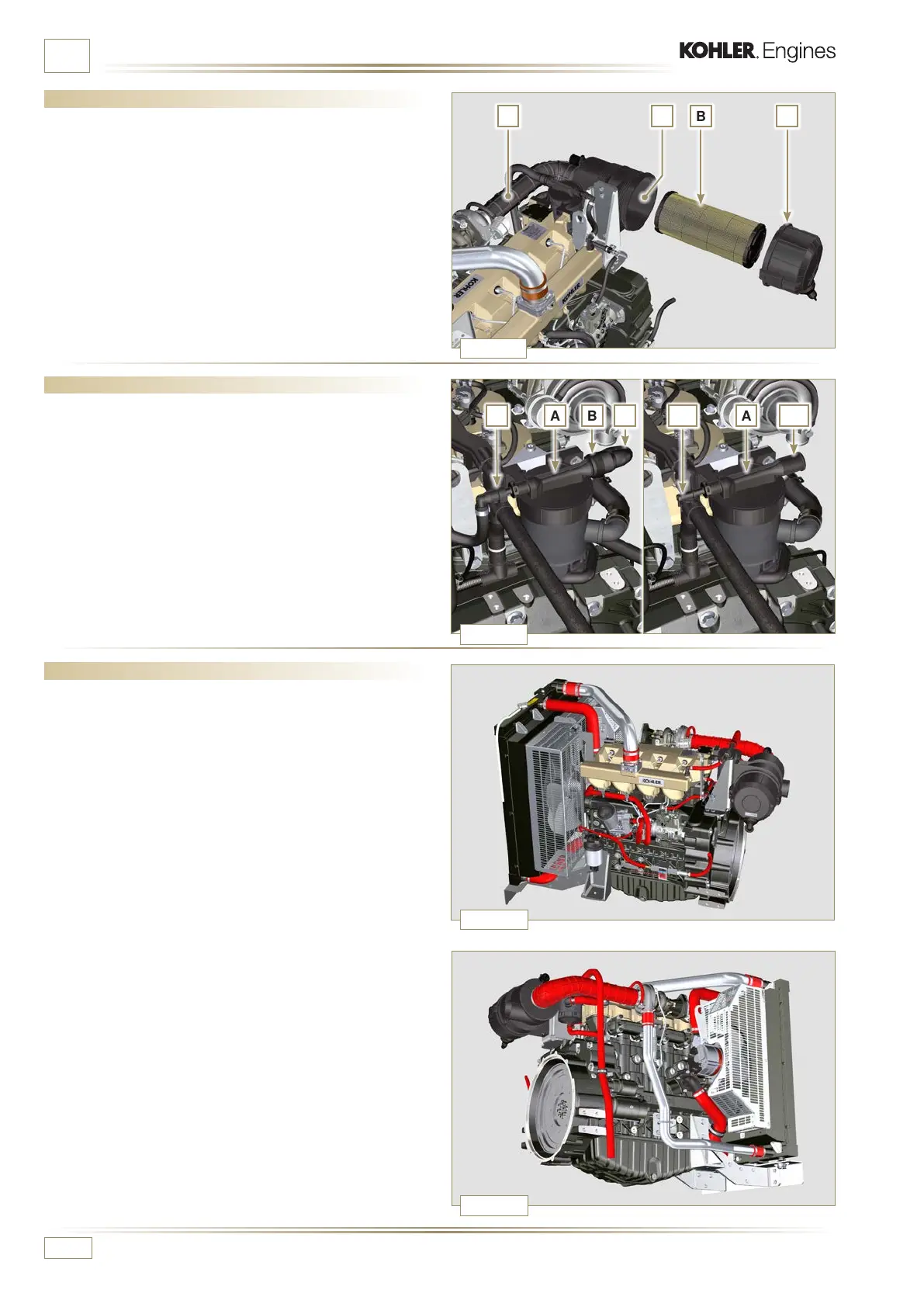

12.4 Rubber hoses and manifolds check

The check is carried out by applying slight deection or

bending along the tube/hose and next to the hose clamps.

C o m p o n e n t s m u s t b e r e p l a c e d i f t h ey h a v e c l e a r s i g n s o f c r a c k s ,

tears, cuts, leaks, or do not retain a certain degree of elasticity.

1 -

Check the condition of all hoses and rubber tubes

highlighted in red in Fig. 12.4 - 12.5.

2 - Check whether there are any leakages of air, coolant, oil or

fuel next to their connections.

NOTE: Refer to the technical documentation of the machine

for components that are not shown in the gure.

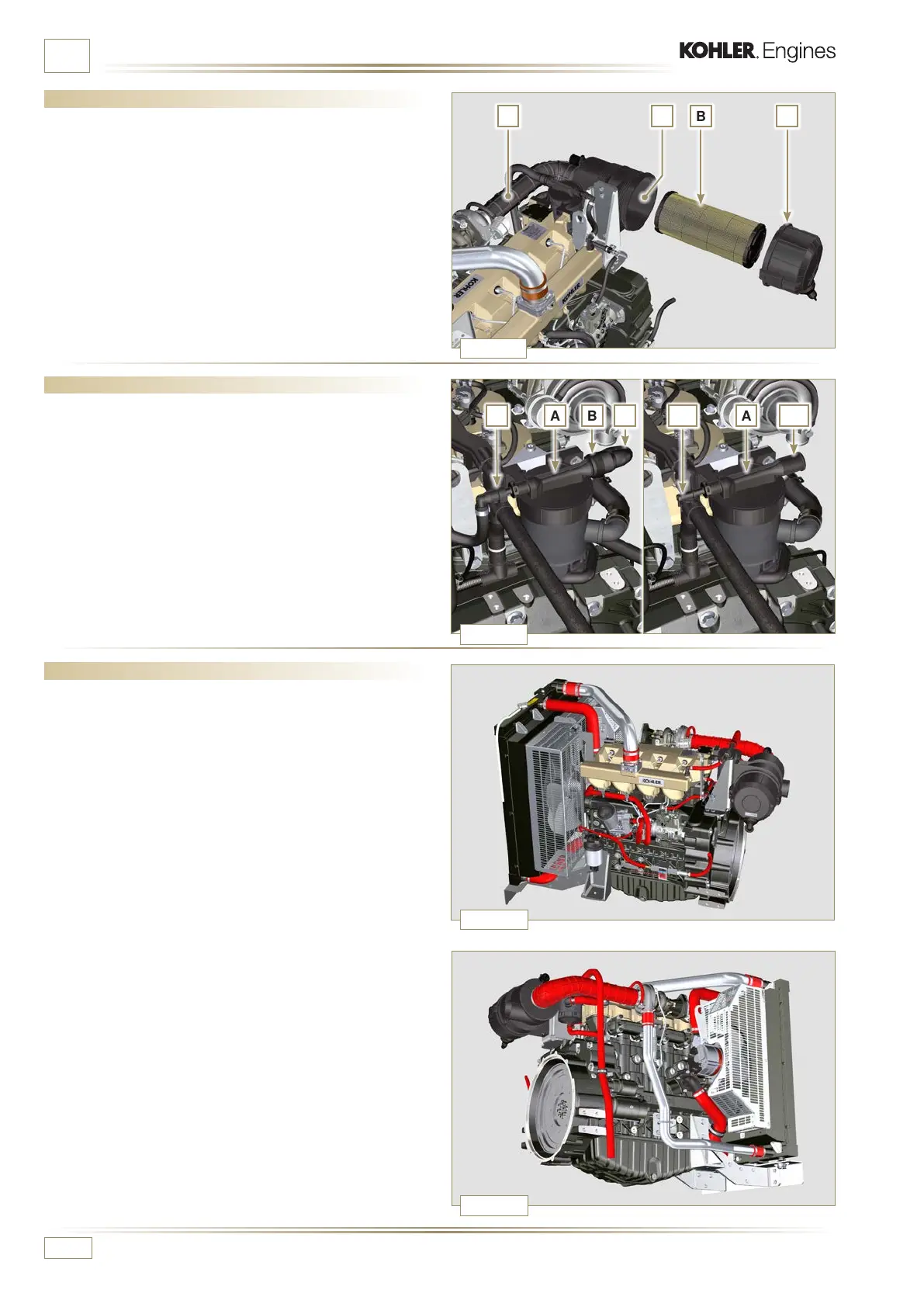

12.2 Air lter check

1 -

Hose A must be completely clean and not damaged.

2 - Air filter cartridge B and its housing C must be completely

clean and free from impurities.

Loading...

Loading...