71

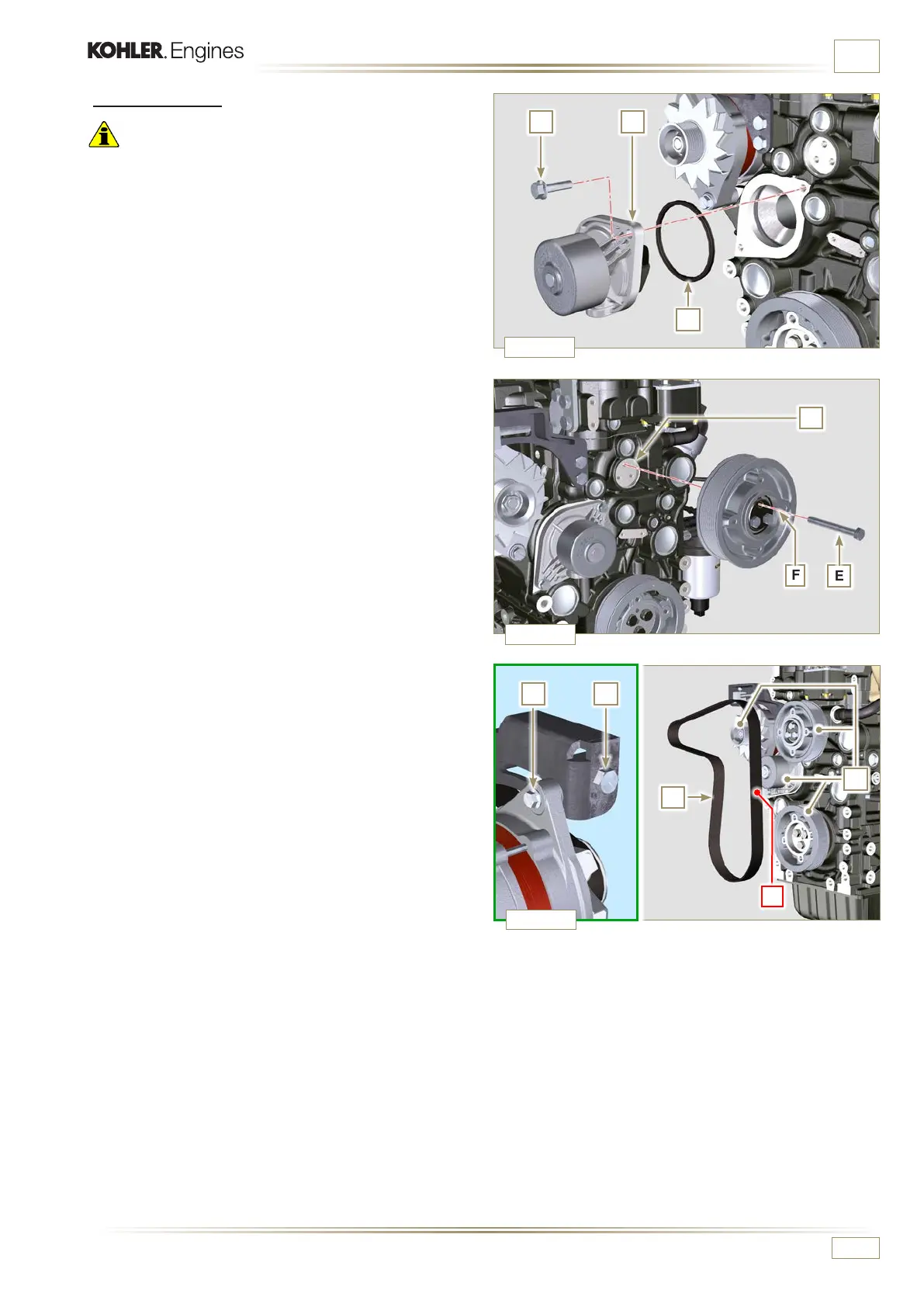

E

F

Fig. 6.35

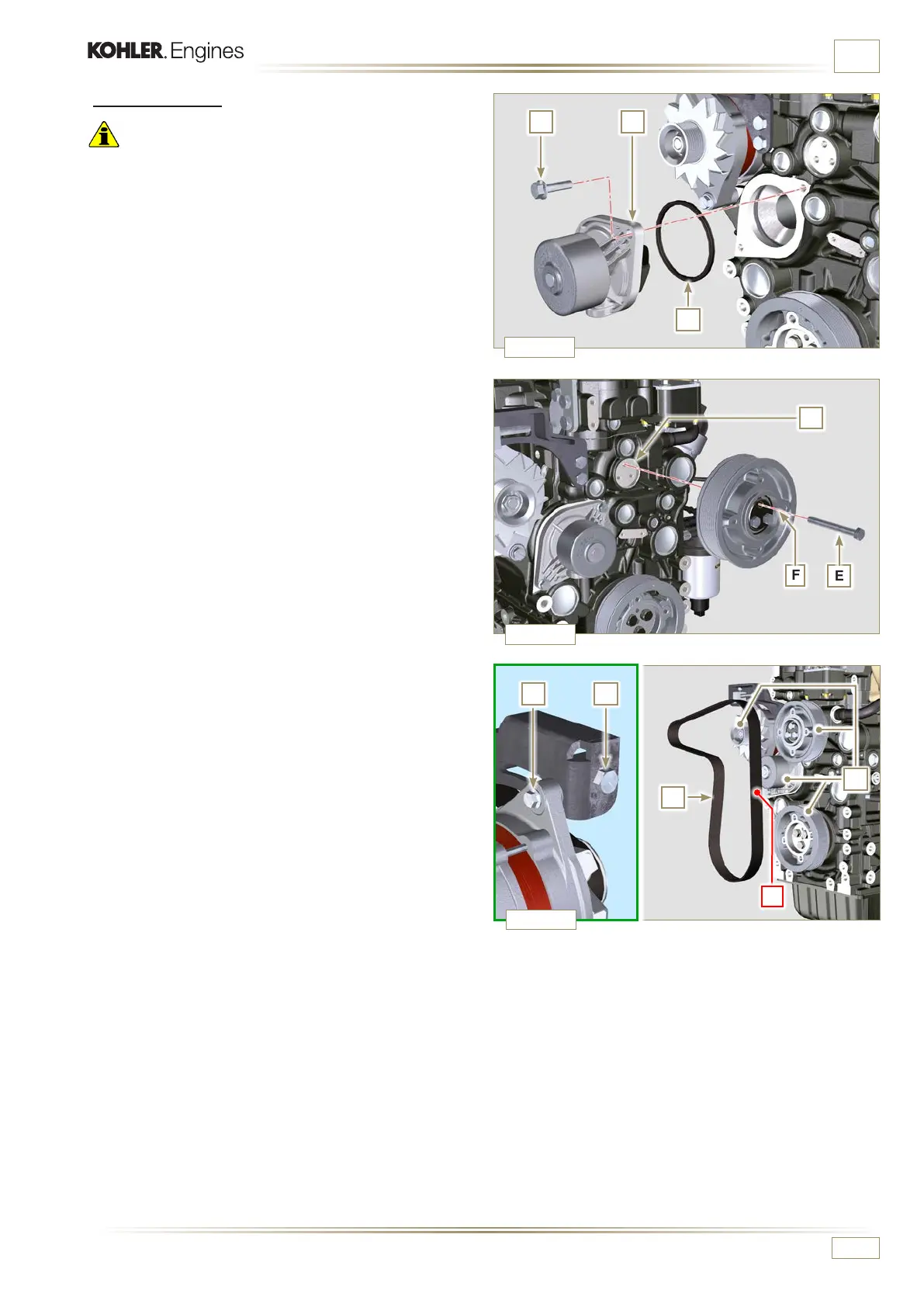

HG

J

A

C

M

D

Fig. 6.37

K

P

Fig. 6.36

ED0053030410

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.2.2 Assembly

Important

• Always replace the gaskets J, at each disassembly.

• Always replace the belt D after each assembly.

1 - Fit the pump H with the screws G interposing the new

gasket J (tightening torque at 25 Nm).

2 -

By means of capscrews E, secure pulley F to crankcase K

(tightening torque at 25 Nm).

3 - Insert the belt D on the pulleys M.

4 - Tighten capscrew C, bringing capscrew A to its stop on the

slot of support.

5 - Fit the screw A (tightening torque at 25 Nm).

6 - Fit the screw B (Fig. 6.32 - tightening torque at 45 Nm).

7 - Start the engine and run it for some minutes, then turn off

it and let it cool down at ambient temperature.

Check by the appropriate tool that at point P the tension

value is between 135 and 178 Hz.

NOTE: If the belt does not comply with the pre-set voltage

values, replace it.

Loading...

Loading...